Rooftop swimming pool heating in Perth, WA

Bowman and Rinnai provide the perfect heating solution for an Australian roof top pool – where winter temperatures can be surprisingly cool!

Used to cool the hot, compressed air from the turbo before it reaches the engine, the intercoolers improve engine efficiency and reduce emissions for marine and land-based stationary engines.

Exhaust gas heat exchangers are designed to recover waste heat energy from the exhaust stream of reciprocating engine powered generating sets.

Bowman 'copper free' fuel coolers are compact, highly efficient heat exchangers suitable for fuel conditioning rigs in the automotive testing industry.

Engine coolant header tank heat exchangers for marine propulsion, gensets or stationary land-based engines.

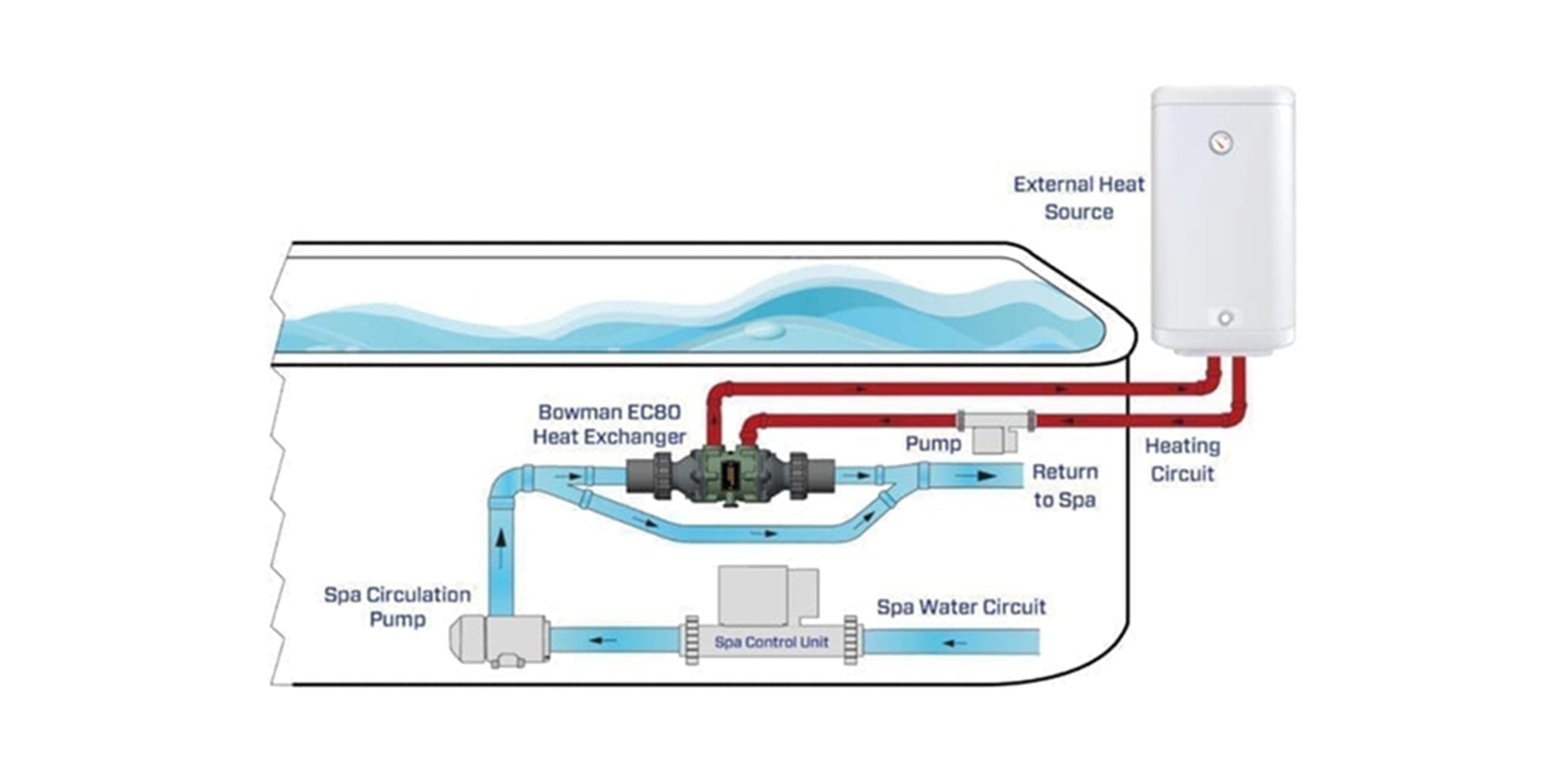

Bowman EC 80-5113-1T heat exchangers provide a new solution for heating spas and hot tubs in just a fraction of the time taken by traditional electric heaters.

Highly efficient heat transfer solutions for cooling marine, land-based and underground hydraulic systems.

Bowman inline plate heat exchangers are a compact, economical solution for high efficiency heat transfer.

Bespoke cooling solutions for a range of popular marine engines from major OEMs, including coolant heat exchangers, charge air coolers, plus combined heat exchangers and exhaust manifolds, suitable for cooling marine engines up to 1 MW.

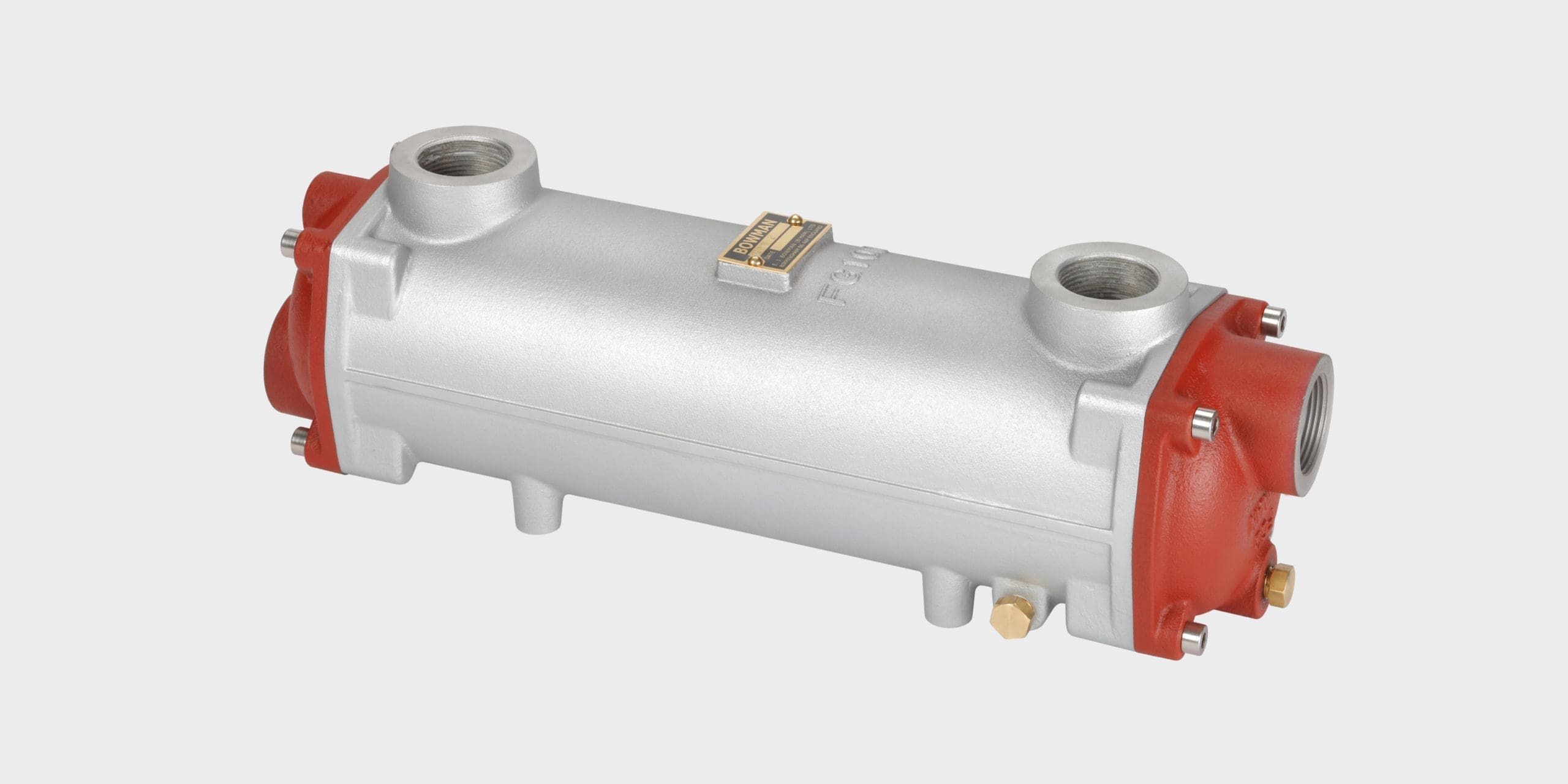

Bowman has a range of highly efficient oil coolers designed for marine and industrial engines and transmissions.

Efficient heat exchangers for cooling electric marine motors, hydrogen fuel cells, battery packs, chargers, AC-DC converters, DC-DC converters, inverters and associated equipment for electric and hybrid marine propulsion and charging systems.

Highly efficient heat transfer solutions for cooling a variety of applications where air and fluids need to be cooled by fluids.

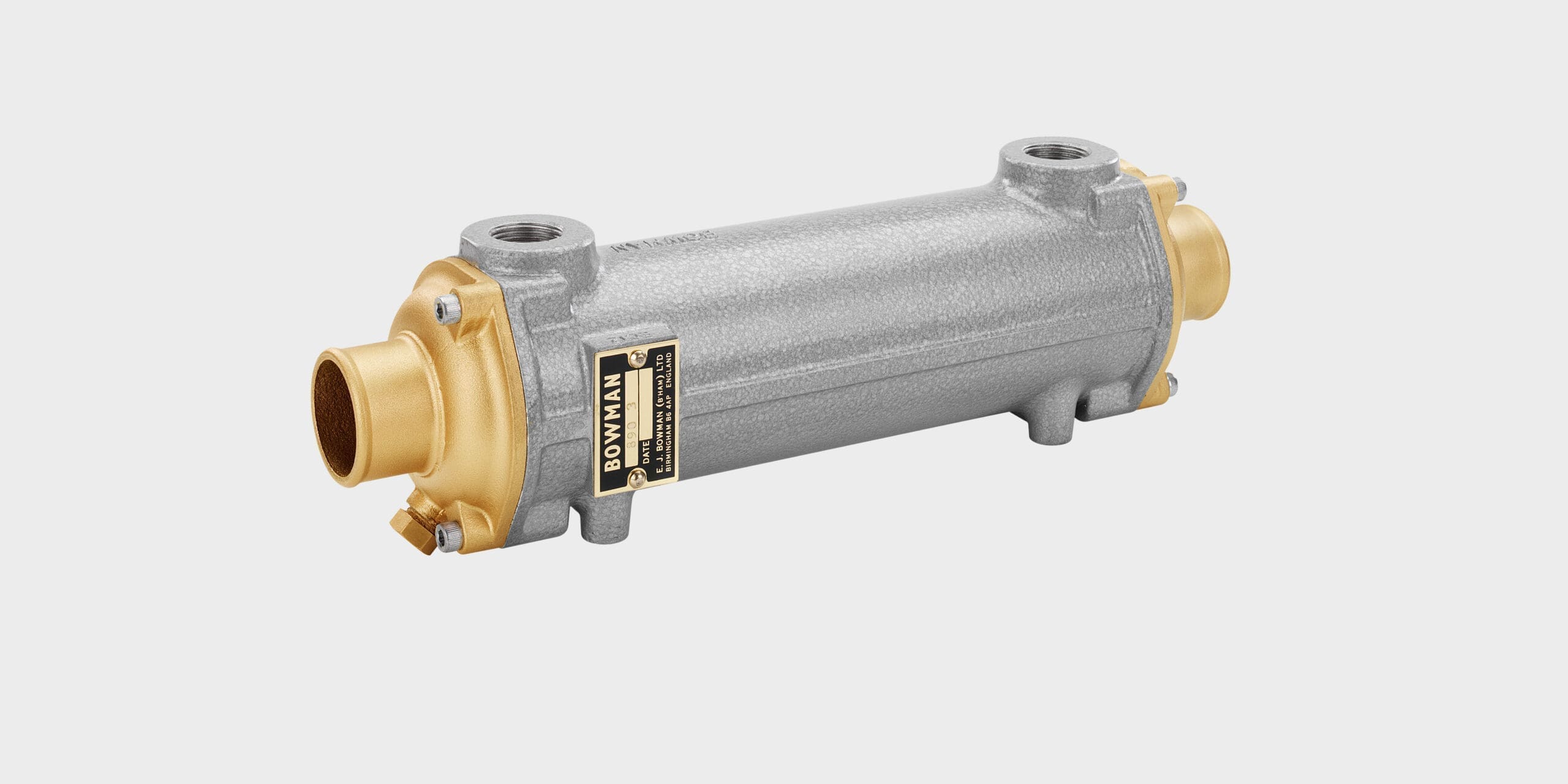

Many applications require stainless steel shell and tube heat exchangers and Bowman provide a standard range of units that are suitable for cooling or heating a variety of fluids.

Bowman swimming pool heat exchangers are renowned for reliability and efficiency. Whether heating your pool with a traditional boiler or a renewable energy source, Bowman is the obvious choice.

Premium quality heat exchangers and oil coolers for precise temperature control of engines under test cell development conditions.

Recovering waste heat energy from engine powered generating sets for biogas, diesel and natural gas applications up to 1 MW.

Efficient cooling for stationary / land-based engines where air cooling is either unavailable or inappropriate.

The reliable solution for cooling Electric & Hybrid Marine Propulsion Systems.

A comprehensive oil cooling solution for industrial hydraulic control systems, plus high temperature and mining applications.

A complete solution for cooling complex on-board hydraulic equipment, including thruster and stabiliser systems.

The complete cooling solution for marine engine propulsion, including the latest electric and hybrid systems.

An energy efficient solution for heating hot tubs and swim spas faster, significantly reducing heat-up time for guest change-over periods.

Quality heat exchangers for efficient swimming pool heating, using boiler or renewable energy heat sources.

Find out more about the company behind these great heat exchangers and oil coolers.

From our earliest beginnings, manufacturing radiators for an automotive industry still in its infancy, to the introduction of our first tubular marine engine oil coolers, and the subsequent development of the shell and tube heat exchanger design that formed the basis of our current range, Bowman has been at the forefront of heat transfer technology for 100 years – Click here to see our full history…

Today Bowman heat exchangers are as renowned for their quality and reliability as they are for their excellent heat transfer performance, which is why they can be found in some of the most challenging industry applications worldwide.

UK designed and manufactured, all Bowman heat exchangers are produced at our 6000 sq. metre manufacturing centre, where high quality standards are maintained throughout the production process.

Extensive stocks of components and finished products are carried at our distribution hub, which is supported by a network of globally based stockists, enabling the company to react quickly to customer requirements and provide fast delivery for our standard product range.

A family run business spanning four generations, today the company exports over 70% of all products manufactured to virtually every industrialised country in the world.

At Bowman we have experienced engineers ready to help and advise you, whether the enquiry is for a product specification, quotation, technical information, order placement, order progressing or finance. Download the leaflet for details of the teams who can provide the information you need and respond to your requests quickly.

Quality is at the heart of Bowman heat exchangers and testament to this is the fact that many of our products are still operating reliably and efficiently, even after 25+ years of service. To ensure quality standards are maintained, we have a highly experienced team, with a thorough knowledge of the product range and the processes employed in their manufacturing and testing. In addition the company holds full ISO 9001:2015 certification and is able to provide witness test to satisfy Lloyds and BV requirements. Read more and download our ISO certificate.

The excellent heat transfer performance of a Bowman heat exchanger is achieved primarily through the innovative design of the tube stack. The sheer number of tubes is much greater than many competitor products’, giving Bowman units a significantly larger surface area from which to transfer heat, whether for cooling an engine or a hydraulic system, or heating a swimming pool or CHP heat energy stream. The tubes run through a series of baffle plates, which not only support the tubes along their entire length, but are also cleverly designed to direct the cooling water in a travel path around and through the tube stack, in a way that delivers optimum heat transfer efficiency.

Bowman heat exchangers are available in a wide range of sizes, material specifications and performance options, including single, two and three pass flow versions, to suit application and cooling requirements. Units are available that are suitable for use with a variety of cooling media, including fresh water, sea water and mineral rich, or contaminated water.

For accurate product selection Bowman has also developed a technical programme to make it easy to select the correct product for an application. Simply by providing us with basic information of temperature, flow, heat dissipation and cooling medium used, we can quickly provide the most appropriate heat exchanger for your requirements.

Bowman heat exchangers can be found operating efficiently and reliably throughout the world, in climatic extremes that range from the freezing depths of an Antarctic winter, to the searing heat of an Australian summer. Whether on land, sea or even deep underground, Bowman heat exchangers have proven themselves to be extremely durable, reliable and thermally efficient time and again. Used extensively throughout the marine industry for both propulsion and hydraulic system cooling, they are also to be found cooling all kinds of land-based engines, heating swimming pools and spas, recovering waste heat within biogas and CHP renewable energy, automotive engine testing, plus pumps, compressors, intercoolers and much more.

And with an international network of stockists and distributors, Bowman heat exchangers are available virtually anywhere in the world.

Bowman and Rinnai provide the perfect heating solution for an Australian roof top pool – where winter temperatures can be surprisingly cool!

Six Bowman heat exchangers have been installed at the recently opened Gold’s Gym, Amman, Jordan, to heat two half Olympic-sized swimming pools.

How Bowman heat exchangers are helping this internationally renowned golf destination reduce energy costs and CO₂ emissions.

Bowman heat exchangers are playing an important role in the success of a flagship hotel on the Black Sea coast in Georgia.

Bowman and Rinnai provide the perfect heating solution for an Australian roof top pool – where winter temperatures can be surprisingly cool!

Six Bowman heat exchangers have been installed at the recently opened Gold’s Gym, Amman, Jordan, to heat two half Olympic-sized swimming pools.

How Bowman heat exchangers are helping this internationally renowned golf destination reduce energy costs and CO₂ emissions.

Bowman heat exchangers are playing an important role in the success of a flagship hotel on the Black Sea coast in Georgia.

If you have a specific enquiry or would like to talk to one of our technical sales engineers, you can contact us by phone or email, using the contact details below. For more general enquiries, simply fill in and return the contact form for a fast response.

Tel: +44 (0)121 359 5401

E-mail: [email protected]

A network of authorised, international Bowman distributors, who hold product stocks and provide local service, is also available.