Bowman is a leading UK manufacturer of shell and tube coolers that deliver highly efficient cooling solutions for a wide range of applications, including compressors, pumps, engines, hydraulic power packs, plastic injection moulding machinery, automotive engine and transmission testing, processing machinery and much more.

The following information offers a general guide to the performance and dimensions of our standard range of shell and tube heat exchangers. For more detailed information on additional configurations and specific applications, please download relevant brochures. Computer aided selection software (CAS) is available to accurately select the correct heat exchanger specifically for your application.

Please contact us or your nearest stockist with the following information to receive a CAS selection:

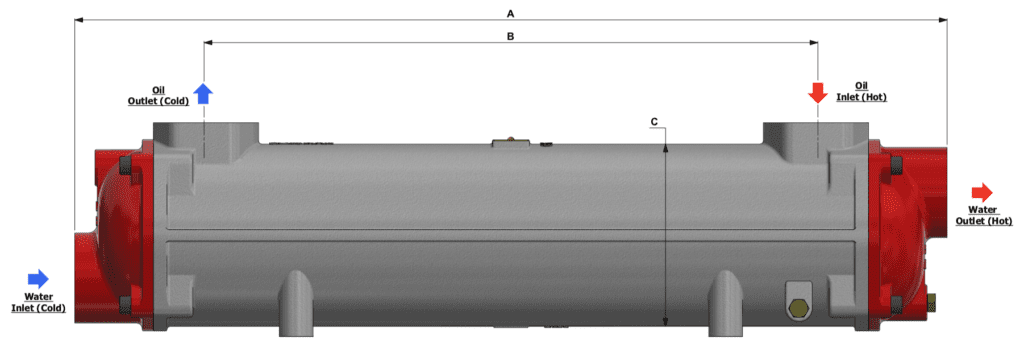

Note – Dimensions in the table below refer to standard three-pass, fresh water heat exchangers. For part numbers and more detailed drawings please download the brochure or contact us.

| Type | Heat Dissipated (kW) | Dim. A (mm) | Dim. B (mm) | Dim. C (mm) | Weight (kg) |

|---|---|---|---|---|---|

| EC80 | 4 | 174 | 60 | 84 | 2.4 |

| EC100 | 9 | 260 | 140 | 84 | 3.2 |

| EC120 | 13 | 346 | 226 | 84 | 3.8 |

| EC140 | 17 | 444 | 324 | 84 | 4.8 |

| EC160 | 22 | 572 | 452 | 84 | 5.7 |

| FC80 | 13 | 272 | 116 | 108 | 5.5 |

| FC100 | 19 | 358 | 202 | 108 | 6.3 |

| FC120 | 26 | 456 | 300 | 108 | 7.3 |

| FC140 | 35 | 584 | 428 | 108 | 9.4 |

| FC160 | 45 | 730 | 574 | 108 | 11.0 |

| FG80 | 28 | 374 | 196 | 128 | 8.5 |

| FG100 | 37 | 472 | 294 | 128 | 10.0 |

| FG120 | 50 | 600 | 422 | 128 | 12.0 |

| FG140 | 62 | 746 | 568 | 128 | 14.5 |

| FG160 | 79 | 924 | 746 | 128 | 17.5 |

| FG200 | 123 | 1330 | 1152 | 128 | 24.0 |

| GL140 | 56 | 502 | 272 | 162 | 18.0 |

| GL180 | 73 | 630 | 400 | 162 | 21.0 |

| GL240 | 93 | 776 | 546 | 162 | 25.0 |

| GL320 | 114 | 954 | 724 | 162 | 30.0 |

| GL400 | 146 | 1156 | 926 | 162 | 36.0 |

| GL480 | 172 | 1360 | 1130 | 162 | 42.0 |

| GK190 | 112 | 674 | 370 | 198 | 34.0 |

| GK250 | 144 | 820 | 516 | 198 | 39.0 |

| GK320 | 181 | 998 | 694 | 198 | 46.0 |

| GK400 | 221 | 1200 | 896 | 198 | 54.0 |

| GK480 | 259 | 1404 | 1100 | 198 | 62.0 |

| GK600 | 329 | 1708 | 1404 | 198 | 74.0 |

| JK190 | 145 | 704 | 340 | 232 | 58.0 |

| JK250 | 186 | 850 | 486 | 232 | 66.0 |

| JK320 | 232 | 1028 | 664 | 232 | 78.0 |

| JK400 | 283 | 1230 | 866 | 232 | 92.0 |

| JK480 | 335 | 1434 | 1070 | 232 | 105.0 |

| JK600 | 401 | 1738 | 1374 | 232 | 126.0 |

| PK190 | 212 | 754 | 330 | 278 | 81.0 |

| PK250 | 270 | 900 | 476 | 278 | 94.0 |

| PK320 | 336 | 1078 | 654 | 278 | 110.0 |

| PK400 | 414 | 1280 | 856 | 278 | 125.0 |

| PK480 | 497 | 1484 | 1060 | 278 | 140.0 |

| PK600 | 660 | 1788 | 1364 | 278 | 158.0 |

| RK400 | 570 | 1392 | 812 | 338 | 186.0 |

| RK600 | 900 | 1900 | 1320 | 338 | 246.0 |