Rooftop swimming pool heating in Perth, WA

Bowman and Rinnai provide the perfect heating solution for an Australian roof top pool – where winter temperatures can be surprisingly cool!

Used to cool the hot, compressed air from the turbo before it reaches the engine, the intercoolers improve engine efficiency and reduce emissions for marine and land-based stationary engines.

Exhaust gas heat exchangers are designed to recover waste heat energy from the exhaust stream of reciprocating engine powered generating sets.

Bowman 'copper free' fuel coolers are compact, highly efficient heat exchangers suitable for fuel conditioning rigs in the automotive testing industry.

Engine coolant header tank heat exchangers for marine propulsion, gensets or stationary land-based engines.

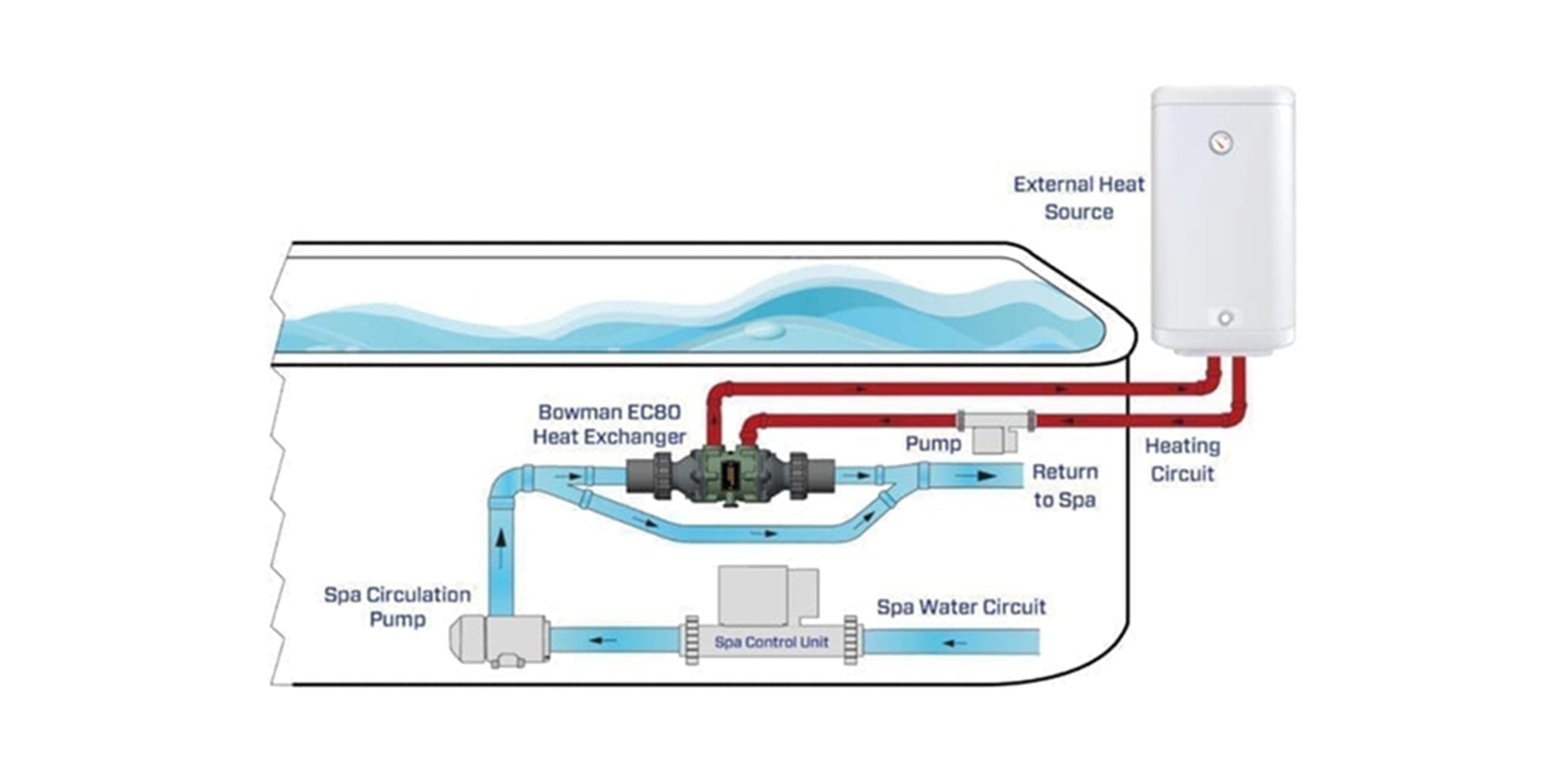

Bowman EC 80-5113-1T heat exchangers provide a new solution for heating spas and hot tubs in just a fraction of the time taken by traditional electric heaters.

Highly efficient heat transfer solutions for cooling marine, land-based and underground hydraulic systems.

Bowman inline plate heat exchangers are a compact, economical solution for high efficiency heat transfer.

Bespoke cooling solutions for a range of popular marine engines from major OEMs, including coolant heat exchangers, charge air coolers, plus combined heat exchangers and exhaust manifolds, suitable for cooling marine engines up to 1 MW.

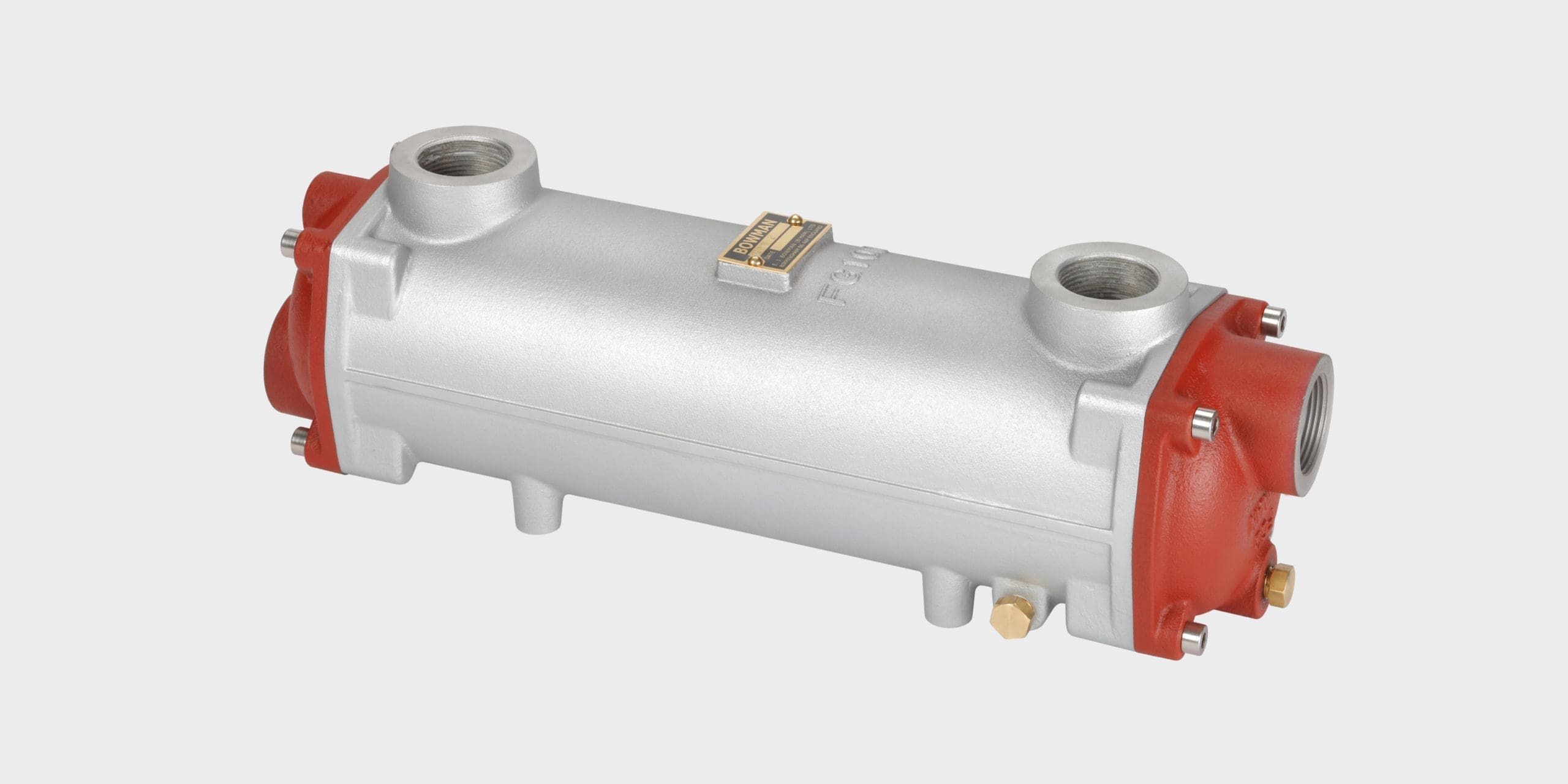

Bowman has a range of highly efficient oil coolers designed for marine and industrial engines and transmissions.

Efficient heat exchangers for cooling electric marine motors, hydrogen fuel cells, battery packs, chargers, AC-DC converters, DC-DC converters, inverters and associated equipment for electric and hybrid marine propulsion and charging systems.

Highly efficient heat transfer solutions for cooling a variety of applications where air and fluids need to be cooled by fluids.

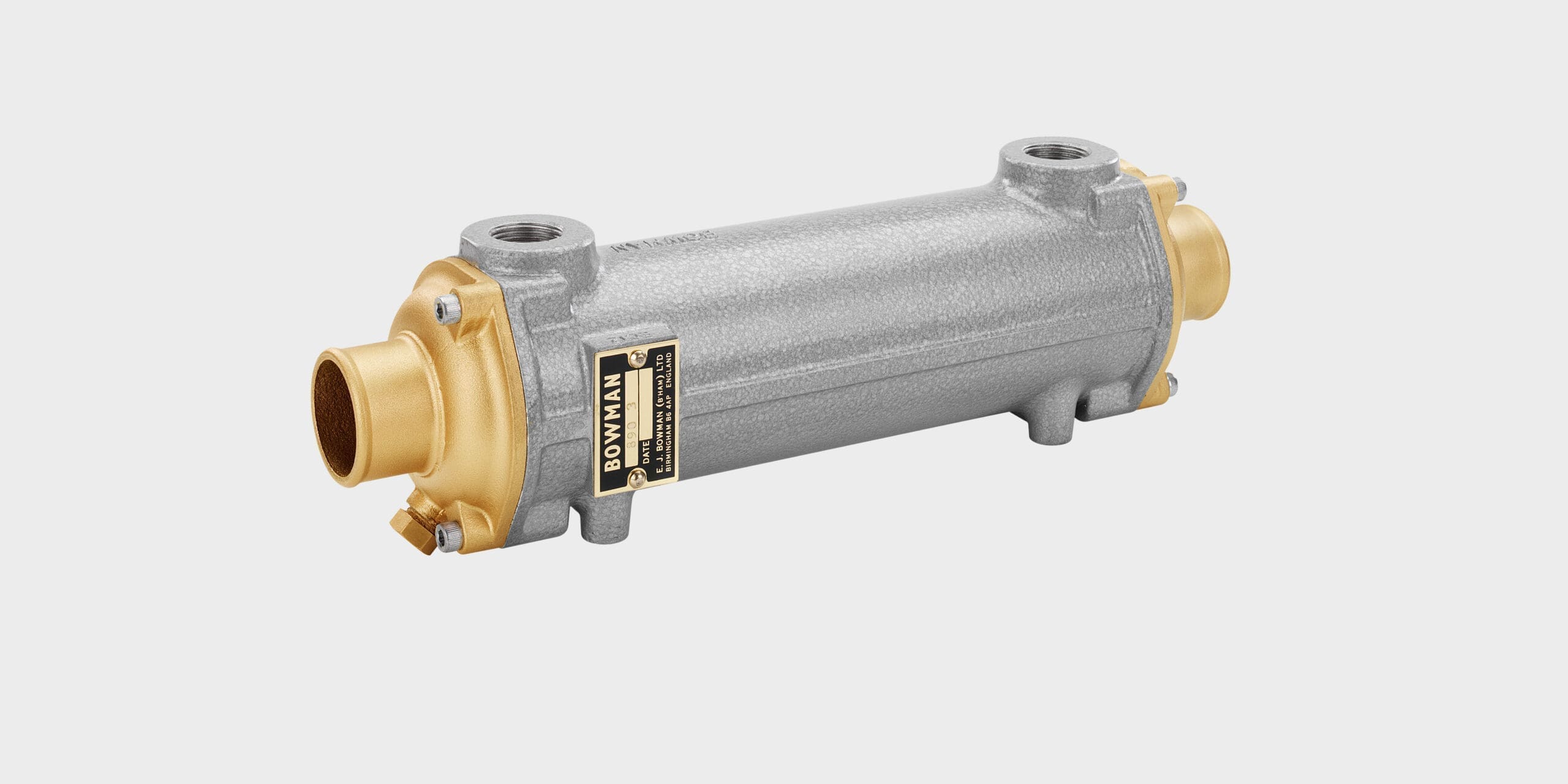

Many applications require stainless steel shell and tube heat exchangers and Bowman provide a standard range of units that are suitable for cooling or heating a variety of fluids.

Bowman swimming pool heat exchangers are renowned for reliability and efficiency. Whether heating your pool with a traditional boiler or a renewable energy source, Bowman is the obvious choice.

Premium quality heat exchangers and oil coolers for precise temperature control of engines under test cell development conditions.

Recovering waste heat energy from engine powered generating sets for biogas, diesel and natural gas applications up to 1 MW.

Efficient cooling for stationary / land-based engines where air cooling is either unavailable or inappropriate.

The reliable solution for cooling Electric & Hybrid Marine Propulsion Systems.

A comprehensive oil cooling solution for industrial hydraulic control systems, plus high temperature and mining applications.

A complete solution for cooling complex on-board hydraulic equipment, including thruster and stabiliser systems.

The complete cooling solution for marine engine propulsion, including the latest electric and hybrid systems.

An energy efficient solution for heating hot tubs and swim spas faster, significantly reducing heat-up time for guest change-over periods.

Quality heat exchangers for efficient swimming pool heating, using boiler or renewable energy heat sources.

Whilst this may not be a problem for coastal leisure craft or ferries, it’s clearly not a perfect solution for larger leisure boats and commercial vessels.

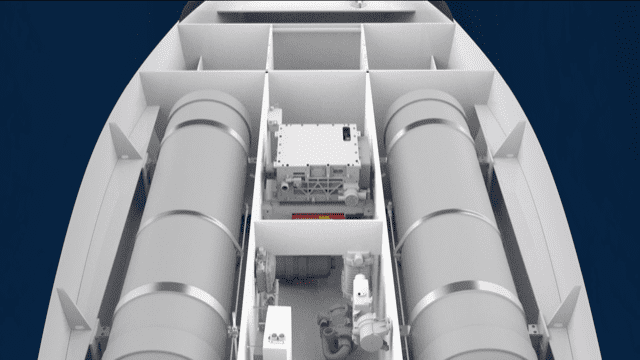

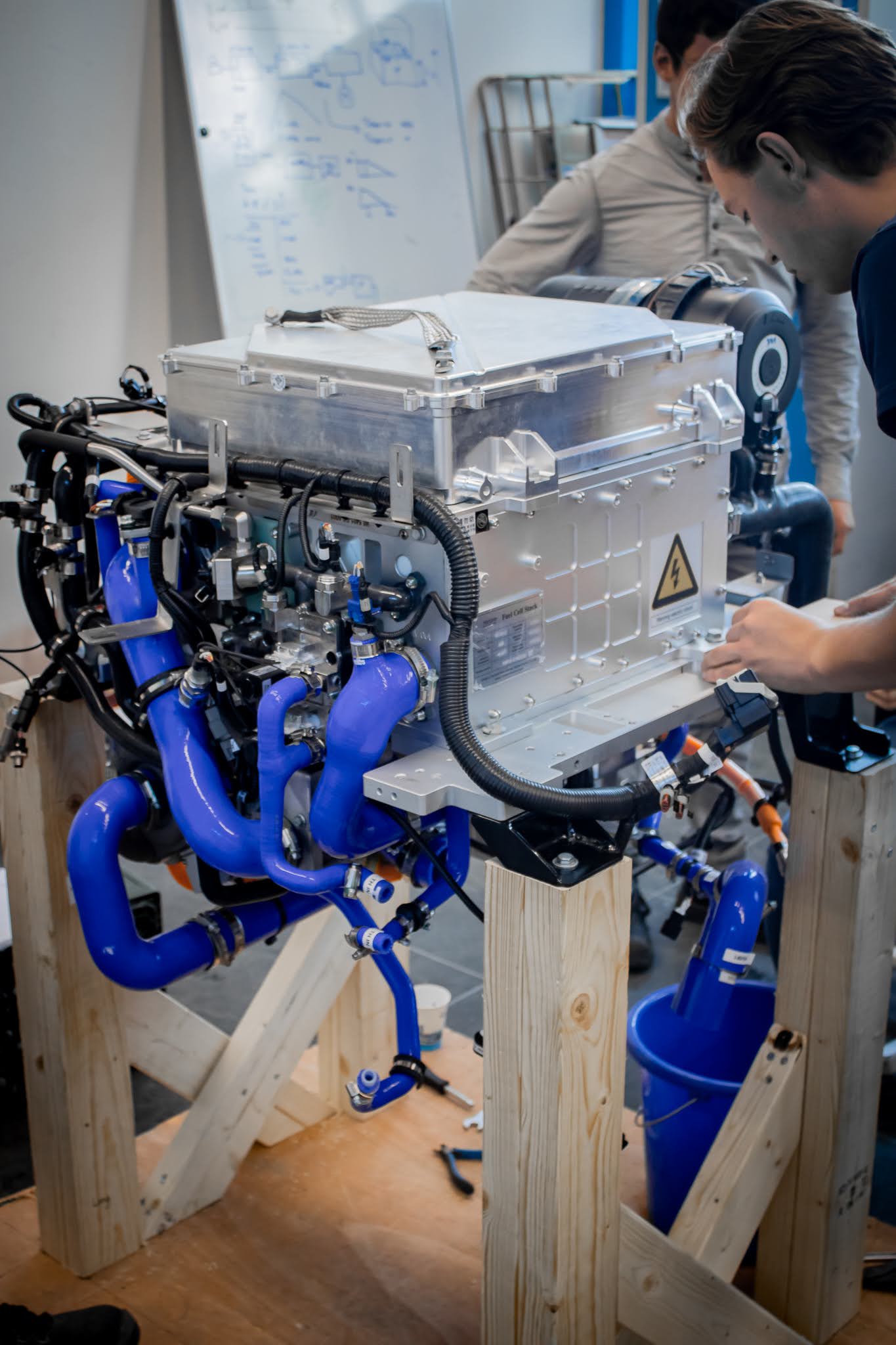

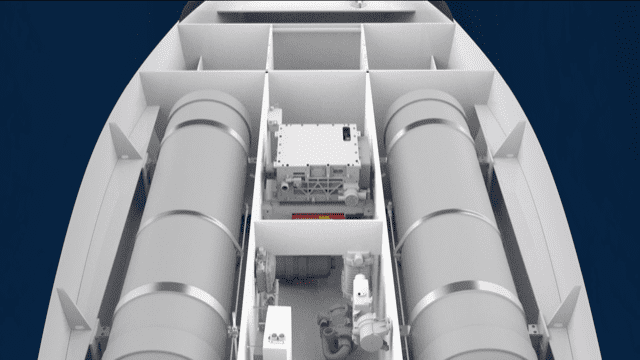

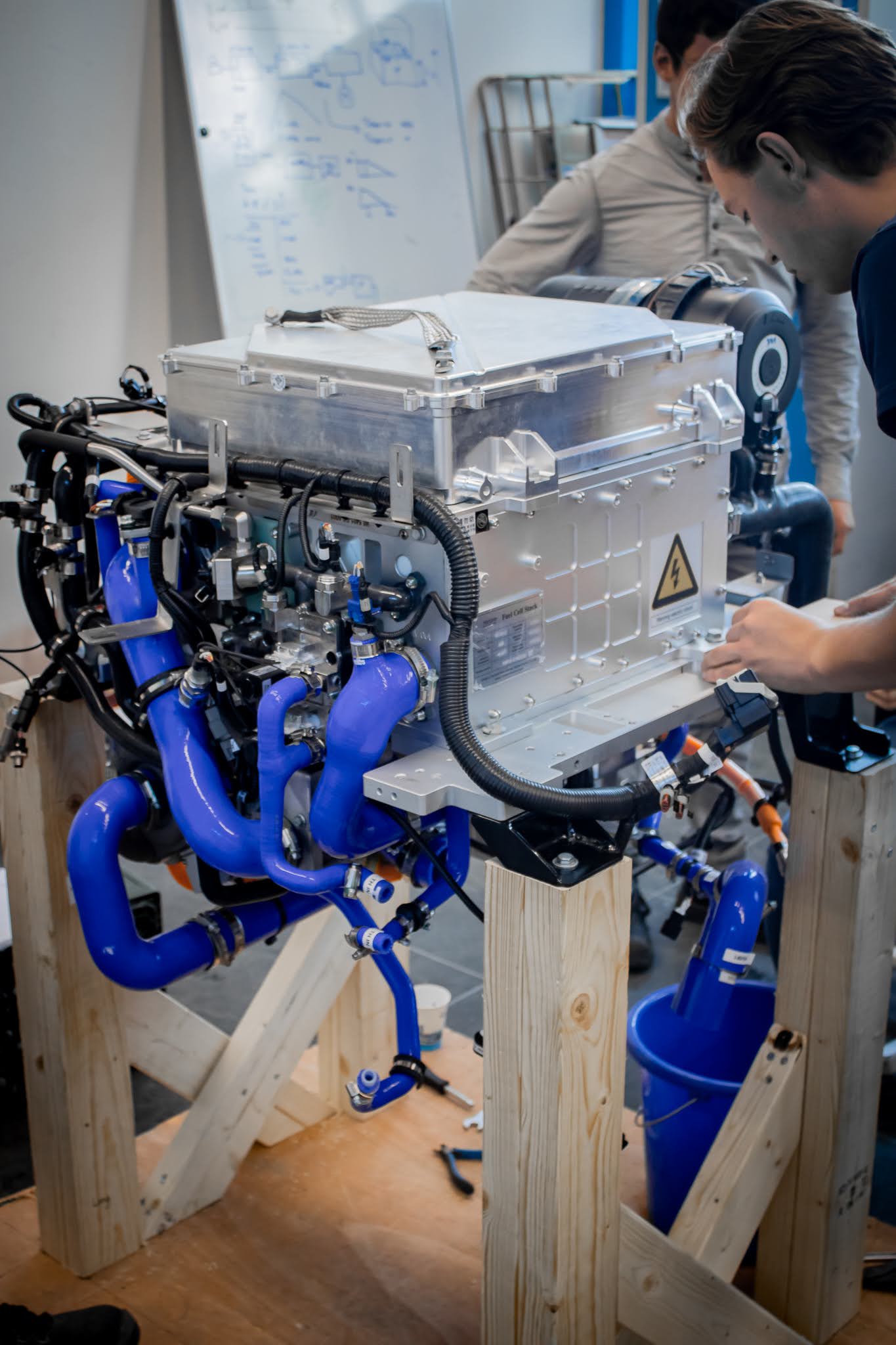

From the outset, Hydro Motion designed the boat specially for hydrogen power. Its mono hull design enabling 16 kg of hydrogen to be stored in a gaseous state at 350 bar, in two 2.3 meters long by 50 cm diameter fuel tanks.

From there, hydrogen is transferred to a fuel cell, where it is mixed with oxygen, generating electricity to power the boat – the only by-product being water.

From there, hydrogen is transferred to a fuel cell, where it is mixed with oxygen, generating electricity to power the boat – the only by-product being water.

Cooling the system and keeping it within optimum temperature range are three Bowman marine specification heat exchangers. Supplied through Bowman’s Dutch distributor KVT, these proved to be efficient and reliable throughout the programme.

The hull design incorporated three hydrofoil ‘wings’, which lift the boat out of the water at speeds of 25 km/h and above. This design reduces drag, enables higher speeds to be achieved and is more energy-efficient.

The World Championship Open Sea Class is designed for green energy powered boats. Teams race in open sea conditions and the event comprises three specific challenges; Manoeuvrability, Speed and Endurance.

The World Championship Open Sea Class is designed for green energy powered boats. Teams race in open sea conditions and the event comprises three specific challenges; Manoeuvrability, Speed and Endurance.

In the manoeuvrability challenge, Hydro Motion came 2nd with an excellent performance over the technically challenging course.

Unfortunately, during the speed challenge, problems with a motor controller forced them to retire.

However, in the endurance challenge, which involved 6 hours of continuous sailing without recharging or refuelling, Hydro Motion stunned the competition, covering 17 laps of the course (the equivalent of 95 km or 51 nautical miles), finishing 7 laps ahead of their nearest competitor, to win the race, whilst having used just 8 kg of hydrogen.

The win lifted them to 2nd overall in the competition, but perhaps their greatest achievement was to demonstrate how hydrogen could be the future in sustainable boating.

Commenting on the performance, Tony Carter, Sales Manager of E J Bowman said, ‘’We are again delighted to be associated with TU Delft. The university has a long history of success in the Monaco Energy Boat Challenge, but this year marked a significant change for them, with the switch from solar power to hydrogen. Bowman heat exchangers are now well-established in the battery/electric marine propulsion market, so we were very pleased to see how well they performed in Hydro Motion’s hydrogen fuel cell competition boat. We look forward to working with them again as they continue to push the boundaries in sustainable boating.’’

For more information on Hydro Motion Team, go to www.hydromotionteam.nl and for Bowman heat exchangers ej-bowman.com.

Pushing The Boundaries In Sustainable Boating

Whilst this may not be a problem for coastal leisure craft or ferries, it’s clearly not a perfect solution for larger leisure boats and commercial vessels.

From the outset, Hydro Motion designed the boat specially for hydrogen power. Its mono hull design enabling 16 kg of hydrogen to be stored in a gaseous state at 350 bar, in two 2.3 meters long by 50 cm diameter fuel tanks.

From there, hydrogen is transferred to a fuel cell, where it is mixed with oxygen, generating electricity to power the boat – the only by-product being water.

From there, hydrogen is transferred to a fuel cell, where it is mixed with oxygen, generating electricity to power the boat – the only by-product being water.

Cooling the system and keeping it within optimum temperature range are three Bowman marine specification heat exchangers. Supplied through Bowman’s Dutch distributor KVT, these proved to be efficient and reliable throughout the programme.

The hull design incorporated three hydrofoil ‘wings’, which lift the boat out of the water at speeds of 25 km/h and above. This design reduces drag, enables higher speeds to be achieved and is more energy-efficient.

The World Championship Open Sea Class is designed for green energy powered boats. Teams race in open sea conditions and the event comprises three specific challenges; Manoeuvrability, Speed and Endurance.

The World Championship Open Sea Class is designed for green energy powered boats. Teams race in open sea conditions and the event comprises three specific challenges; Manoeuvrability, Speed and Endurance.

In the manoeuvrability challenge, Hydro Motion came 2nd with an excellent performance over the technically challenging course.

Unfortunately, during the speed challenge, problems with a motor controller forced them to retire.

However, in the endurance challenge, which involved 6 hours of continuous sailing without recharging or refuelling, Hydro Motion stunned the competition, covering 17 laps of the course (the equivalent of 95 km or 51 nautical miles), finishing 7 laps ahead of their nearest competitor, to win the race, whilst having used just 8 kg of hydrogen.

The win lifted them to 2nd overall in the competition, but perhaps their greatest achievement was to demonstrate how hydrogen could be the future in sustainable boating.

Commenting on the performance, Tony Carter, Sales Manager of E J Bowman said, ‘’We are again delighted to be associated with TU Delft. The university has a long history of success in the Monaco Energy Boat Challenge, but this year marked a significant change for them, with the switch from solar power to hydrogen. Bowman heat exchangers are now well-established in the battery/electric marine propulsion market, so we were very pleased to see how well they performed in Hydro Motion’s hydrogen fuel cell competition boat. We look forward to working with them again as they continue to push the boundaries in sustainable boating.’’

For more information on Hydro Motion Team, go to www.hydromotionteam.nl and for Bowman heat exchangers ej-bowman.com.

More News from EJ Bowman

Bowman and Rinnai provide the perfect heating solution for an Australian roof top pool – where winter temperatures can be surprisingly cool!

Six Bowman heat exchangers have been installed at the recently opened Gold’s Gym, Amman, Jordan, to heat two half Olympic-sized swimming pools.

How Bowman heat exchangers are helping this internationally renowned golf destination reduce energy costs and CO₂ emissions.

Bowman heat exchangers are playing an important role in the success of a flagship hotel on the Black Sea coast in Georgia.

Bowman and Rinnai provide the perfect heating solution for an Australian roof top pool – where winter temperatures can be surprisingly cool!

Six Bowman heat exchangers have been installed at the recently opened Gold’s Gym, Amman, Jordan, to heat two half Olympic-sized swimming pools.

How Bowman heat exchangers are helping this internationally renowned golf destination reduce energy costs and CO₂ emissions.

Bowman heat exchangers are playing an important role in the success of a flagship hotel on the Black Sea coast in Georgia.