Rooftop swimming pool heating in Perth, WA

Bowman and Rinnai provide the perfect heating solution for an Australian roof top pool – where winter temperatures can be surprisingly cool!

Used to cool the hot, compressed air from the turbo before it reaches the engine, the intercoolers improve engine efficiency and reduce emissions for marine and land-based stationary engines.

Exhaust gas heat exchangers are designed to recover waste heat energy from the exhaust stream of reciprocating engine powered generating sets.

Bowman 'copper free' fuel coolers are compact, highly efficient heat exchangers suitable for fuel conditioning rigs in the automotive testing industry.

Engine coolant header tank heat exchangers for marine propulsion, gensets or stationary land-based engines.

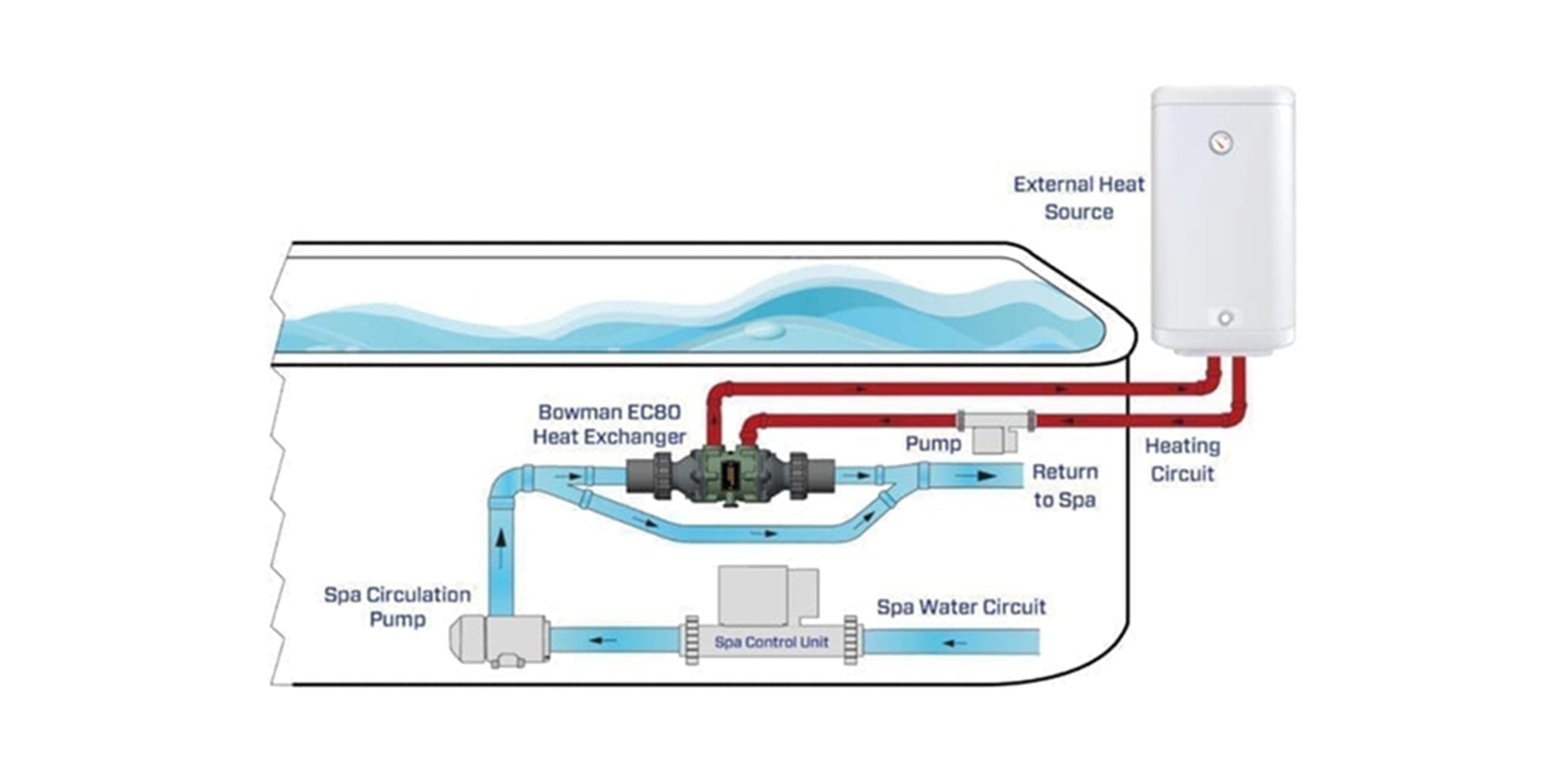

Bowman EC 80-5113-1T heat exchangers provide a new solution for heating spas and hot tubs in just a fraction of the time taken by traditional electric heaters.

Highly efficient heat transfer solutions for cooling marine, land-based and underground hydraulic systems.

Bowman inline plate heat exchangers are a compact, economical solution for high efficiency heat transfer.

Bespoke cooling solutions for a range of popular marine engines from major OEMs, including coolant heat exchangers, charge air coolers, plus combined heat exchangers and exhaust manifolds, suitable for cooling marine engines up to 1 MW.

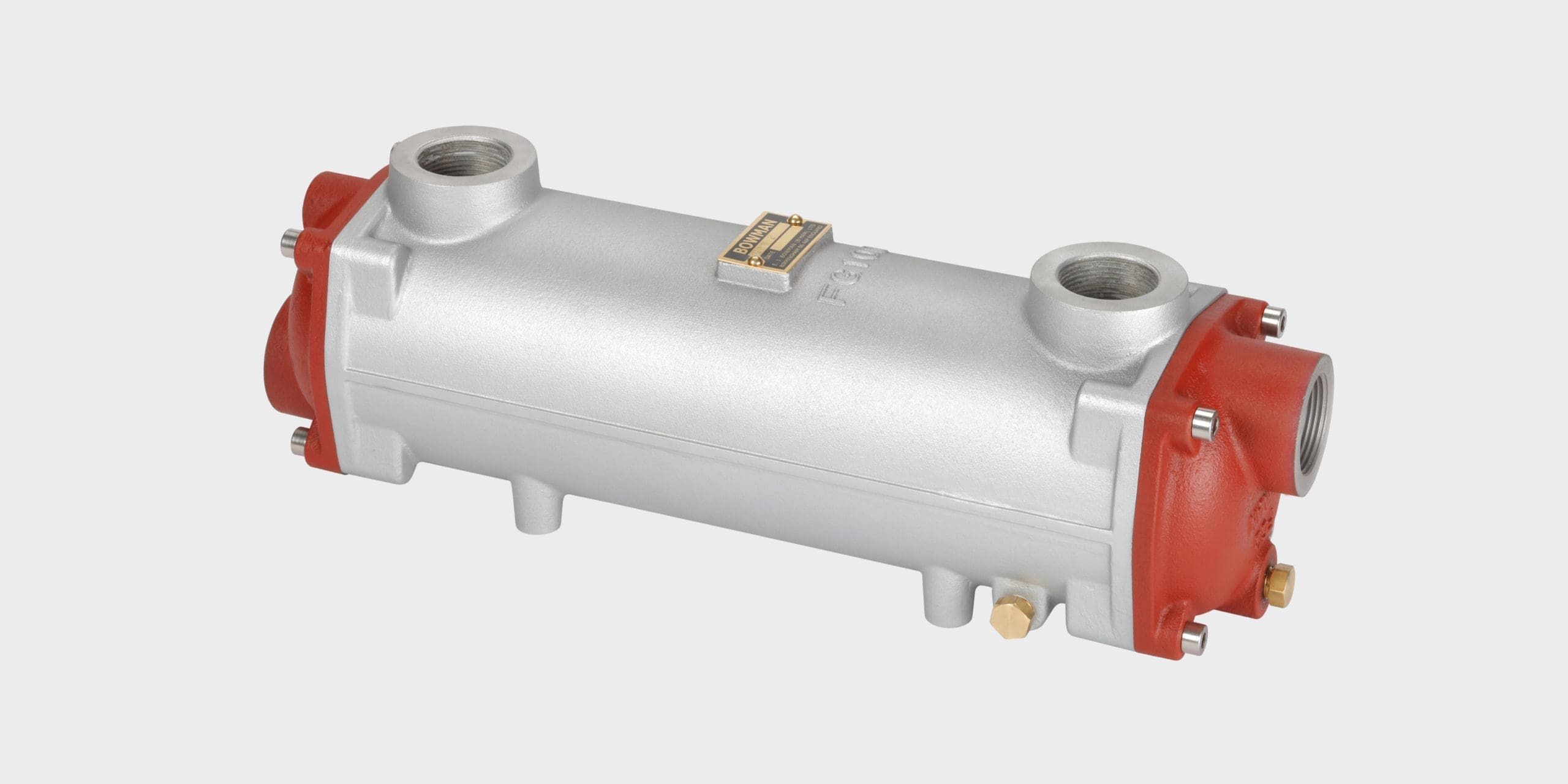

Bowman has a range of highly efficient oil coolers designed for marine and industrial engines and transmissions.

Efficient heat exchangers for cooling electric marine motors, hydrogen fuel cells, battery packs, chargers, AC-DC converters, DC-DC converters, inverters and associated equipment for electric and hybrid marine propulsion and charging systems.

Highly efficient heat transfer solutions for cooling a variety of applications where air and fluids need to be cooled by fluids.

Many applications require stainless steel shell and tube heat exchangers and Bowman provide a standard range of units that are suitable for cooling or heating a variety of fluids.

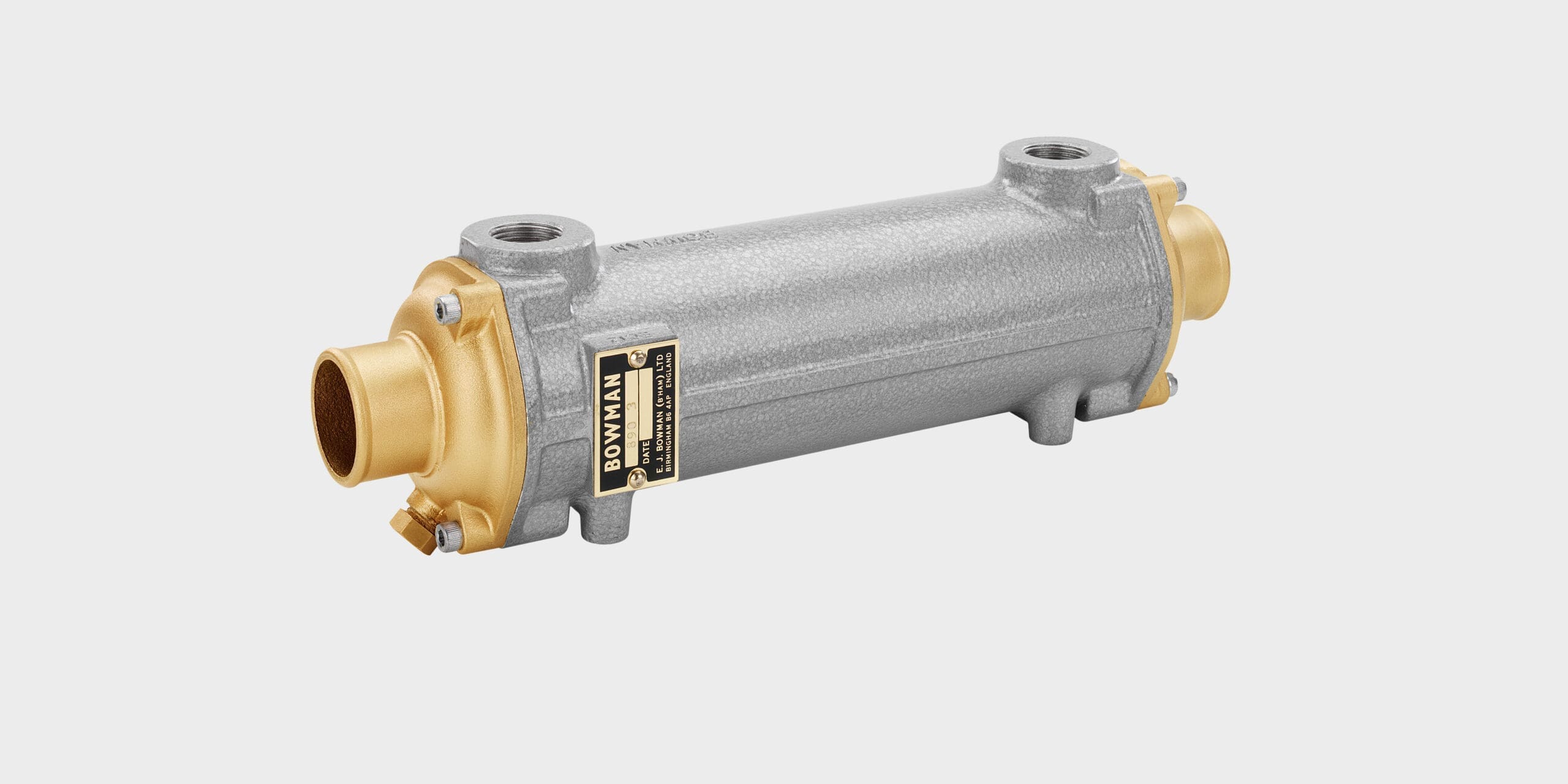

Bowman swimming pool heat exchangers are renowned for reliability and efficiency. Whether heating your pool with a traditional boiler or a renewable energy source, Bowman is the obvious choice.

Premium quality heat exchangers and oil coolers for precise temperature control of engines under test cell development conditions.

Recovering waste heat energy from engine powered generating sets for biogas, diesel and natural gas applications up to 1 MW.

Efficient cooling for stationary / land-based engines where air cooling is either unavailable or inappropriate.

The reliable solution for cooling Electric & Hybrid Marine Propulsion Systems.

A comprehensive oil cooling solution for industrial hydraulic control systems, plus high temperature and mining applications.

A complete solution for cooling complex on-board hydraulic equipment, including thruster and stabiliser systems.

The complete cooling solution for marine engine propulsion, including the latest electric and hybrid systems.

An energy efficient solution for heating hot tubs and swim spas faster, significantly reducing heat-up time for guest change-over periods.

Quality heat exchangers for efficient swimming pool heating, using boiler or renewable energy heat sources.

Bowman heat exchangers are playing a vital role in the success of a ‘zero waste’ recycling centre.

Anaerobic digestion (AD) has revolutionised the way that food waste can be handled on a commercial scale. No longer is it lost to landfill, as specialist recycling companies now convert it to energy for homes and businesses.

One such company is Biogen, who operate 7 recycling centres around the UK and its latest operation, located near Atherstone, Warwickshire, processes over 45,000 tons of food waste every year!

Over 110 tons of food waste is delivered every day, where it is bulk loaded into a ‘de-packaging’ line, to separate the food waste from associated packaging. The food waste then travels through a series of processing operations, to prepare it for the AD process.

Two anaerobic digesters operating at 40 °C, complete a digestion cycle every 40 days, which ensures the maximum energy value is recovered from the waste. The AD process produces a combustible gas containing Methane CH4 (60%) and CO2 (40%), which is used to power the company’s two GE Jenbacher generators.

The electricity produced from the generators is fed into the National Grid and provides enough power for 4,500 homes.

Waste heat is also recovered from the generators’ cooling system and this is transferred through two Bowman FC160-1426-5 heat exchangers to provide hot water for three primary areas – building services, including the underfloor heating system, plus personal hygiene facilities; the waste packaging ‘hot wash’ process, to remove any remaining food waste and avoid cross contamination; plus jet washing of all commercial vehicles prior to them leaving the site.

Waste heat is also recovered from the generators’ cooling system and this is transferred through two Bowman FC160-1426-5 heat exchangers to provide hot water for three primary areas – building services, including the underfloor heating system, plus personal hygiene facilities; the waste packaging ‘hot wash’ process, to remove any remaining food waste and avoid cross contamination; plus jet washing of all commercial vehicles prior to them leaving the site.

Remaining solids are sent off site for further processing, whilst remaining liquids provide a nutrient rich fertiliser for local farmers, ensuring that literally no waste material is sent to landfill.

‘The Bowman heat exchangers perform a vital role within the plant’, said site manager Kevin Eagles, ‘they not only cool the generator engines, they also provide hot water for vital process cleaning operations and ensure the offices and staff areas are always warm and comfortable’.

Bowman heat exchangers are playing a vital role in the success of a ‘zero waste’ recycling centre.

Anaerobic digestion (AD) has revolutionised the way that food waste can be handled on a commercial scale. No longer is it lost to landfill, as specialist recycling companies now convert it to energy for homes and businesses.

One such company is Biogen, who operate 7 recycling centres around the UK and its latest operation, located near Atherstone, Warwickshire, processes over 45,000 tons of food waste every year!

Over 110 tons of food waste is delivered every day, where it is bulk loaded into a ‘de-packaging’ line, to separate the food waste from associated packaging. The food waste then travels through a series of processing operations, to prepare it for the AD process.

Two anaerobic digesters operating at 40 °C, complete a digestion cycle every 40 days, which ensures the maximum energy value is recovered from the waste. The AD process produces a combustible gas containing Methane CH4 (60%) and CO2 (40%), which is used to power the company’s two GE Jenbacher generators.

The electricity produced from the generators is fed into the National Grid and provides enough power for 4,500 homes.

Waste heat is also recovered from the generators’ cooling system and this is transferred through two Bowman FC160-1426-5 heat exchangers to provide hot water for three primary areas – building services, including the underfloor heating system, plus personal hygiene facilities; the waste packaging ‘hot wash’ process, to remove any remaining food waste and avoid cross contamination; plus jet washing of all commercial vehicles prior to them leaving the site.

Waste heat is also recovered from the generators’ cooling system and this is transferred through two Bowman FC160-1426-5 heat exchangers to provide hot water for three primary areas – building services, including the underfloor heating system, plus personal hygiene facilities; the waste packaging ‘hot wash’ process, to remove any remaining food waste and avoid cross contamination; plus jet washing of all commercial vehicles prior to them leaving the site.

Remaining solids are sent off site for further processing, whilst remaining liquids provide a nutrient rich fertiliser for local farmers, ensuring that literally no waste material is sent to landfill.

‘The Bowman heat exchangers perform a vital role within the plant’, said site manager Kevin Eagles, ‘they not only cool the generator engines, they also provide hot water for vital process cleaning operations and ensure the offices and staff areas are always warm and comfortable’.

More News from EJ Bowman

Bowman and Rinnai provide the perfect heating solution for an Australian roof top pool – where winter temperatures can be surprisingly cool!

Six Bowman heat exchangers have been installed at the recently opened Gold’s Gym, Amman, Jordan, to heat two half Olympic-sized swimming pools.

How Bowman heat exchangers are helping this internationally renowned golf destination reduce energy costs and CO₂ emissions.

Bowman heat exchangers are playing an important role in the success of a flagship hotel on the Black Sea coast in Georgia.

Bowman and Rinnai provide the perfect heating solution for an Australian roof top pool – where winter temperatures can be surprisingly cool!

Six Bowman heat exchangers have been installed at the recently opened Gold’s Gym, Amman, Jordan, to heat two half Olympic-sized swimming pools.

How Bowman heat exchangers are helping this internationally renowned golf destination reduce energy costs and CO₂ emissions.

Bowman heat exchangers are playing an important role in the success of a flagship hotel on the Black Sea coast in Georgia.