Rooftop swimming pool heating in Perth, WA

Bowman and Rinnai provide the perfect heating solution for an Australian roof top pool – where winter temperatures can be surprisingly cool!

Used to cool the hot, compressed air from the turbo before it reaches the engine, the intercoolers improve engine efficiency and reduce emissions for marine and land-based stationary engines.

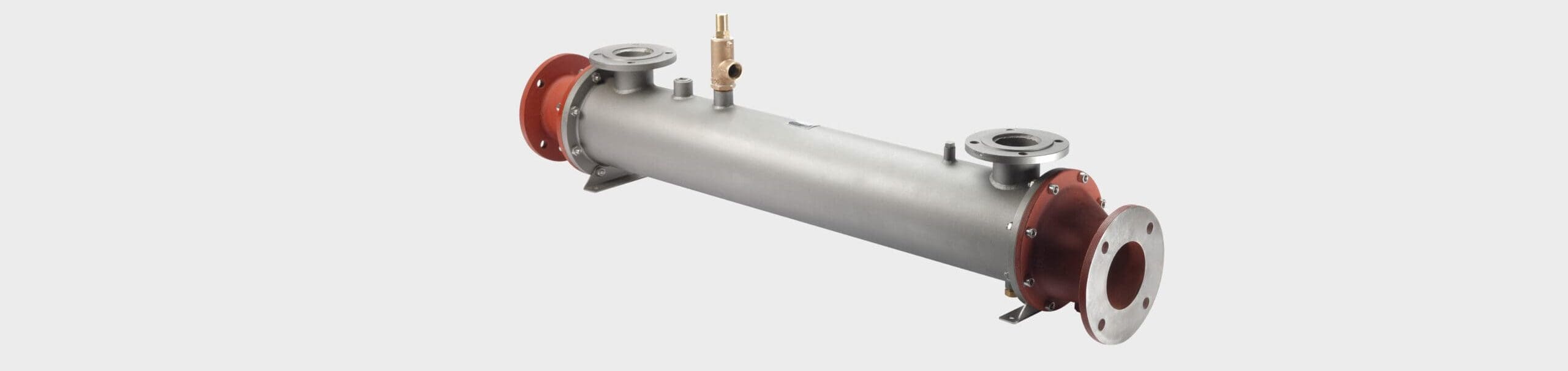

Exhaust gas heat exchangers are designed to recover waste heat energy from the exhaust stream of reciprocating engine powered generating sets.

Bowman 'copper free' fuel coolers are compact, highly efficient heat exchangers suitable for fuel conditioning rigs in the automotive testing industry.

Engine coolant header tank heat exchangers for marine propulsion, gensets or stationary land-based engines.

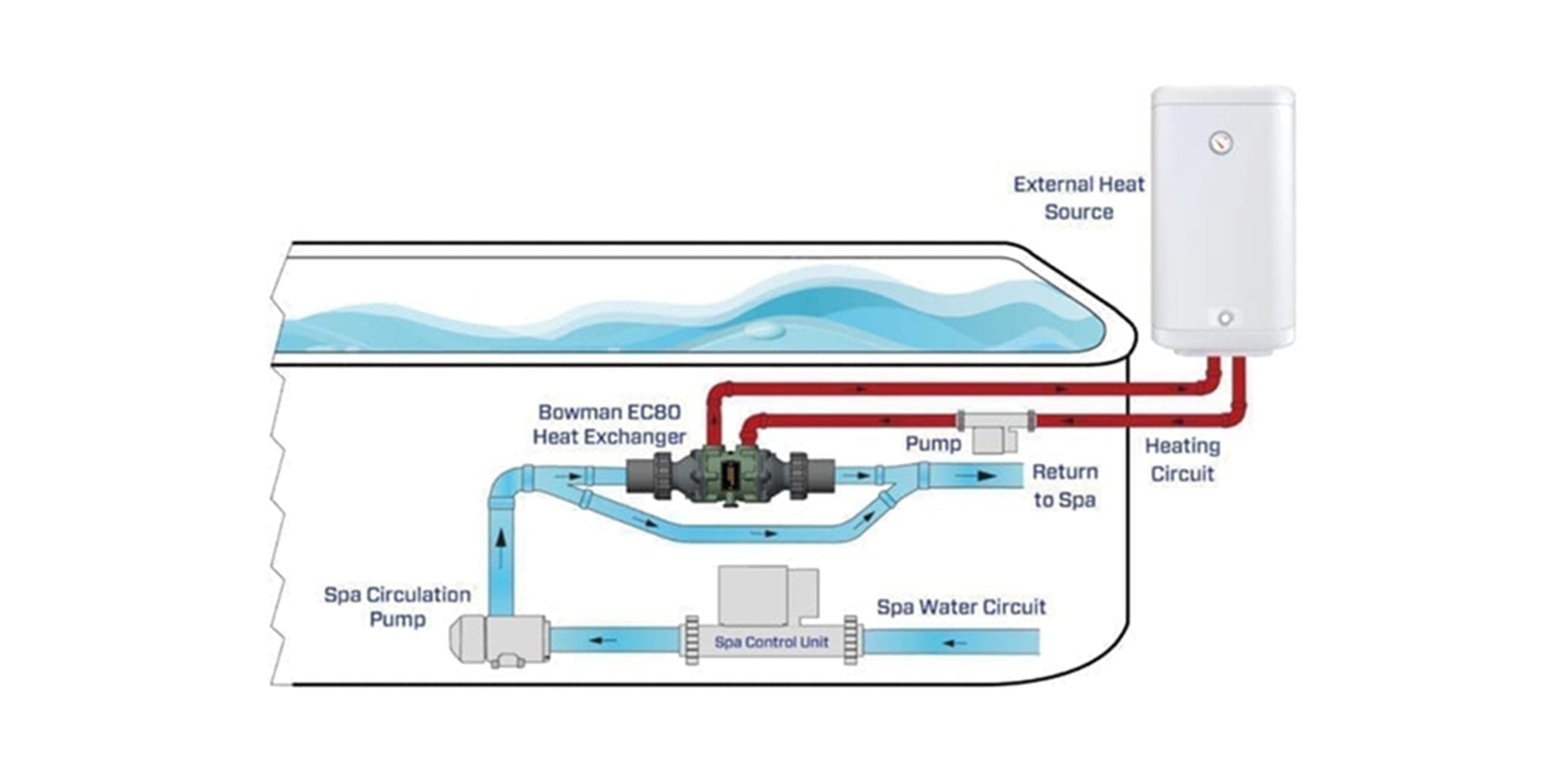

Bowman EC 80-5113-1T heat exchangers provide a new solution for heating spas and hot tubs in just a fraction of the time taken by traditional electric heaters.

Highly efficient heat transfer solutions for cooling marine, land-based and underground hydraulic systems.

Bowman inline plate heat exchangers are a compact, economical solution for high efficiency heat transfer.

Bespoke cooling solutions for a range of popular marine engines from major OEMs, including coolant heat exchangers, charge air coolers, plus combined heat exchangers and exhaust manifolds, suitable for cooling marine engines up to 1 MW.

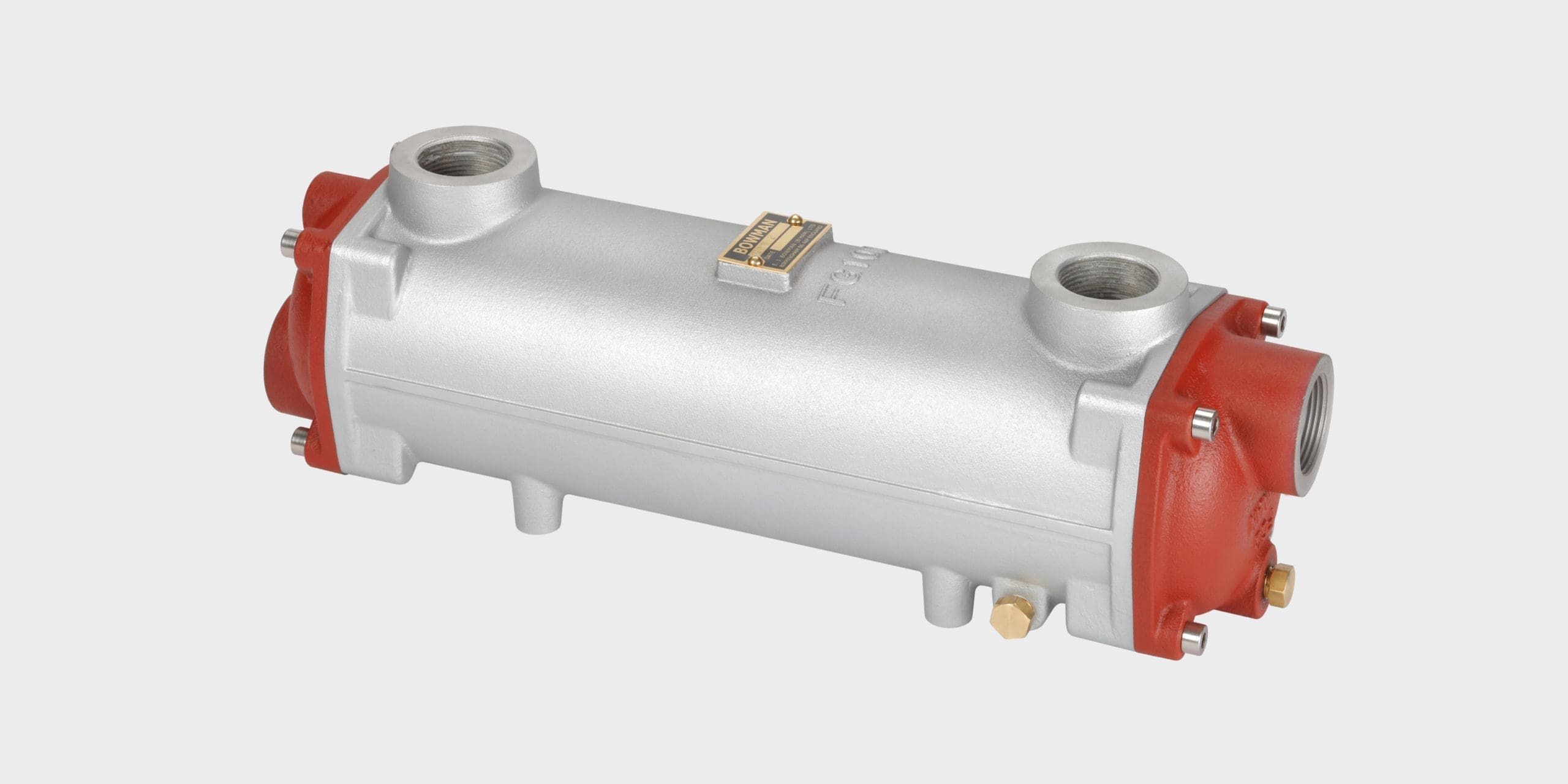

Bowman has a range of highly efficient oil coolers designed for marine and industrial engines and transmissions.

Efficient heat exchangers for cooling electric marine motors, hydrogen fuel cells, battery packs, chargers, AC-DC converters, DC-DC converters, inverters and associated equipment for electric and hybrid marine propulsion and charging systems.

Highly efficient heat transfer solutions for cooling a variety of applications where air and fluids need to be cooled by fluids.

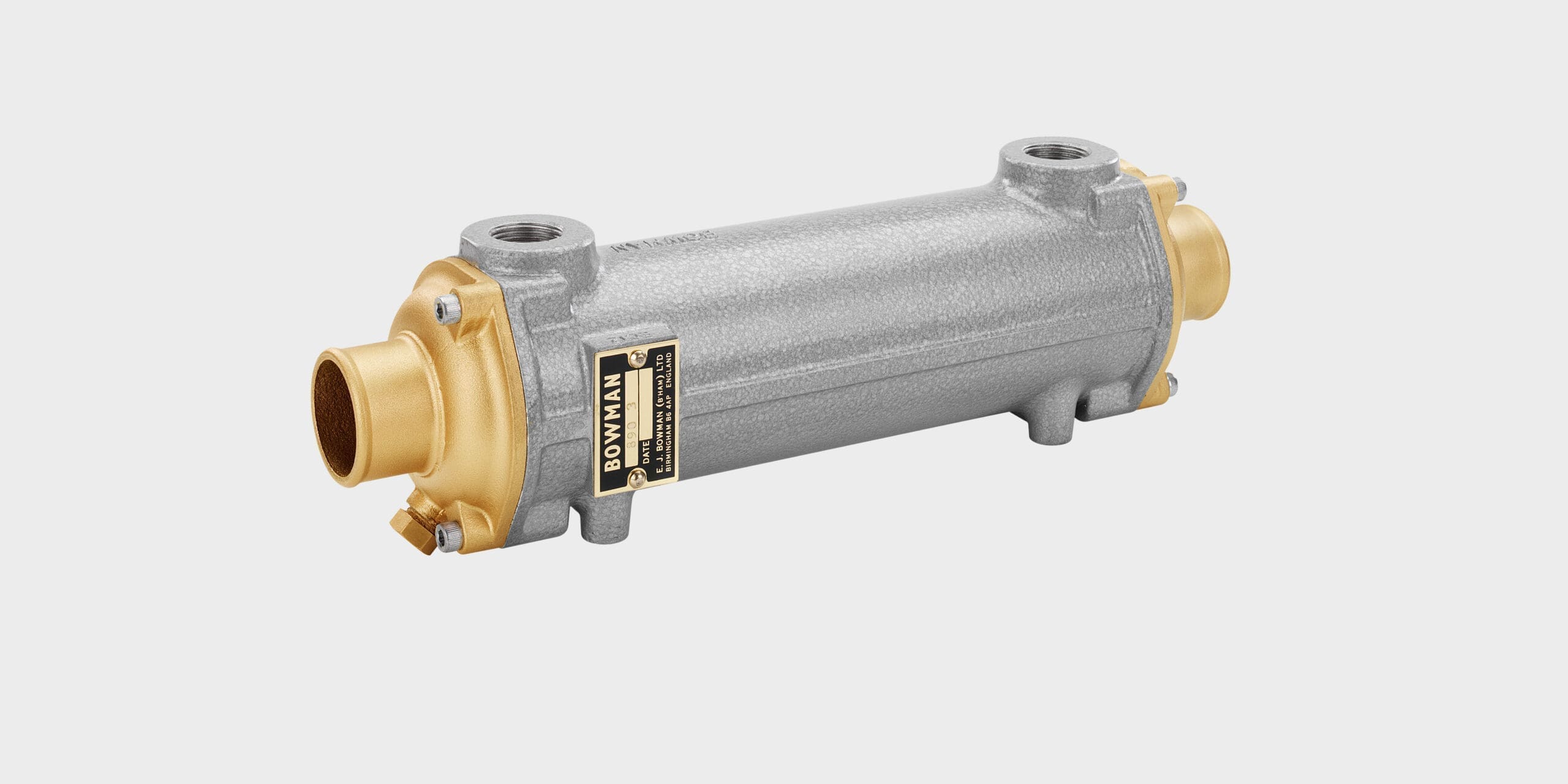

Many applications require stainless steel shell and tube heat exchangers and Bowman provide a standard range of units that are suitable for cooling or heating a variety of fluids.

Bowman swimming pool heat exchangers are renowned for reliability and efficiency. Whether heating your pool with a traditional boiler or a renewable energy source, Bowman is the obvious choice.

Premium quality heat exchangers and oil coolers for precise temperature control of engines under test cell development conditions.

Recovering waste heat energy from engine powered generating sets for biogas, diesel and natural gas applications up to 1 MW.

Efficient cooling for stationary / land-based engines where air cooling is either unavailable or inappropriate.

The reliable solution for cooling Electric & Hybrid Marine Propulsion Systems.

A comprehensive oil cooling solution for industrial hydraulic control systems, plus high temperature and mining applications.

A complete solution for cooling complex on-board hydraulic equipment, including thruster and stabiliser systems.

The complete cooling solution for marine engine propulsion, including the latest electric and hybrid systems.

An energy efficient solution for heating hot tubs and swim spas faster, significantly reducing heat-up time for guest change-over periods.

Quality heat exchangers for efficient swimming pool heating, using boiler or renewable energy heat sources.

An engine exhaust produces waste heat – and lots of it! Find out how an exhaust gas heat exchanger converts this heat into a valuable ‘free’ energy source.

An exhaust gas heat exchanger recovers heat energy from the exhaust gases of a reciprocating diesel, gas or bio gas fuelled engine and utilises this energy to heat water, which can then be used for space or process heating, cooling, via a chiller system, or generating more electricity, via an ORC system. When added to an engine powered generating set, it converts the engine from ‘Power Only’ to ‘Combined Heat and Power’ (CHP), increasing its overall efficiency significantly.

Operating principle

A reciprocating engine converts fuel into power. A by-product of this process is the creation of heat, which is generated in every part of the engine. However, the largest single area of heat generation is from the exhaust system. Up to 50% of all fuel energy used to power the engine is turned into heat and of this heat 55% comes from the engine’s exhaust system. Without some form of heat recovery this valuable energy source would simply be lost into the earth’s atmosphere. However, by installing an exhaust gas heat exchanger into the engine’s exhaust stream, it can be recovered and used for a variety of heating or cooling requirements, at no additional cost, in terms of fuel used.

How does it work?

Exhaust gases exit the engine at temperatures in excess of 500 °C, passing through the heat exchanger’s central ‘tube core’. Simultaneously, water is circulated around the outer ‘shell’ of the heat exchanger, travelling over and around the tube core, cooling the exhaust gases and transferring much of the heat in the gases to the water circuit.

What can the heat be used for?

What can the heat be used for?

Exhaust gas heat exchangers capture waste heat from flue like gases during energy generation. This system transfers the residual heat to a secondary medium, like heating water. It improves energy efficiency by repurposing heat that would otherwise be lost, reducing fuel consumption and costs.

Benefits to the end user

In addition to capturing this valuable ‘free energy’ source, the exhaust gas heat exchanger also improves the overall efficiency of a gen-set, increasing it from around 30% (power only) to around 60% (CHP). This can be improved to around 80% efficiency, when waste heat is recovered from other areas of the engine, such as the cooling, lubrication and air induction systems.

Things to consider

Consideration must be given to the amount of heat recovered from the exhaust stream, as the exhaust temperature should not normally be allowed to drop below 120 °C (or 180 °C on diesel powered engines), in order to avoid fouling or condensation forming inside the heat exchanger, which could lead to premature failure.

Automatic engine shutdown equipment must also be installed with temperature probes located in both the exhaust gas heat exchanger and the engine. Should the gas circuit shut down, it is important that the water circuit continues to operate for a period of time to enable residual heat to disperse from the heat exchanger.

In summary

Exhaust gas heat exchangers are an extremely efficient way of recovering a valuable energy resource that would otherwise be lost. Once recovered, the energy can be utilised for a range of uses, which contribute to reducing energy costs. As the UK’s leading manufacturer of exhaust gas heat exchangers, Bowman offer a wide range of high-quality units for applications up to 1 MW using biogas, diesel or natural gas, which are proven in some of the most challenging installations on earth.

For further information on Bowman exhaust gas heat exchangers, download our product brochure or contact our technical sales team on +44 (0)121 359 5401.

An engine exhaust produces waste heat – and lots of it! Find out how an exhaust gas heat exchanger converts this heat into a valuable ‘free’ energy source.

An exhaust gas heat exchanger recovers heat energy from the exhaust gases of a reciprocating diesel, gas or bio gas fuelled engine and utilises this energy to heat water, which can then be used for space or process heating, cooling, via a chiller system, or generating more electricity, via an ORC system. When added to an engine powered generating set, it converts the engine from ‘Power Only’ to ‘Combined Heat and Power’ (CHP), increasing its overall efficiency significantly.

Operating principle

A reciprocating engine converts fuel into power. A by-product of this process is the creation of heat, which is generated in every part of the engine. However, the largest single area of heat generation is from the exhaust system. Up to 50% of all fuel energy used to power the engine is turned into heat and of this heat 55% comes from the engine’s exhaust system. Without some form of heat recovery this valuable energy source would simply be lost into the earth’s atmosphere. However, by installing an exhaust gas heat exchanger into the engine’s exhaust stream, it can be recovered and used for a variety of heating or cooling requirements, at no additional cost, in terms of fuel used.

How does it work?

Exhaust gases exit the engine at temperatures in excess of 500 °C, passing through the heat exchanger’s central ‘tube core’. Simultaneously, water is circulated around the outer ‘shell’ of the heat exchanger, travelling over and around the tube core, cooling the exhaust gases and transferring much of the heat in the gases to the water circuit.

What can the heat be used for?

What can the heat be used for?

Exhaust gas heat exchangers capture waste heat from flue like gases during energy generation. This system transfers the residual heat to a secondary medium, like heating water. It improves energy efficiency by repurposing heat that would otherwise be lost, reducing fuel consumption and costs.

Benefits to the end user

In addition to capturing this valuable ‘free energy’ source, the exhaust gas heat exchanger also improves the overall efficiency of a gen-set, increasing it from around 30% (power only) to around 60% (CHP). This can be improved to around 80% efficiency, when waste heat is recovered from other areas of the engine, such as the cooling, lubrication and air induction systems.

Things to consider

Consideration must be given to the amount of heat recovered from the exhaust stream, as the exhaust temperature should not normally be allowed to drop below 120 °C (or 180 °C on diesel powered engines), in order to avoid fouling or condensation forming inside the heat exchanger, which could lead to premature failure.

Automatic engine shutdown equipment must also be installed with temperature probes located in both the exhaust gas heat exchanger and the engine. Should the gas circuit shut down, it is important that the water circuit continues to operate for a period of time to enable residual heat to disperse from the heat exchanger.

In summary

Exhaust gas heat exchangers are an extremely efficient way of recovering a valuable energy resource that would otherwise be lost. Once recovered, the energy can be utilised for a range of uses, which contribute to reducing energy costs. As the UK’s leading manufacturer of exhaust gas heat exchangers, Bowman offer a wide range of high-quality units for applications up to 1 MW using biogas, diesel or natural gas, which are proven in some of the most challenging installations on earth.

For further information on Bowman exhaust gas heat exchangers, download our product brochure or contact our technical sales team on +44 (0)121 359 5401.

Bowman and Rinnai provide the perfect heating solution for an Australian roof top pool – where winter temperatures can be surprisingly cool!

Six Bowman heat exchangers have been installed at the recently opened Gold’s Gym, Amman, Jordan, to heat two half Olympic-sized swimming pools.

How Bowman heat exchangers are helping this internationally renowned golf destination reduce energy costs and CO₂ emissions.

Bowman heat exchangers are playing an important role in the success of a flagship hotel on the Black Sea coast in Georgia.

Bowman and Rinnai provide the perfect heating solution for an Australian roof top pool – where winter temperatures can be surprisingly cool!

Six Bowman heat exchangers have been installed at the recently opened Gold’s Gym, Amman, Jordan, to heat two half Olympic-sized swimming pools.

How Bowman heat exchangers are helping this internationally renowned golf destination reduce energy costs and CO₂ emissions.

Bowman heat exchangers are playing an important role in the success of a flagship hotel on the Black Sea coast in Georgia.