Rooftop swimming pool heating in Perth, WA

Bowman and Rinnai provide the perfect heating solution for an Australian roof top pool – where winter temperatures can be surprisingly cool!

Used to cool the hot, compressed air from the turbo before it reaches the engine, the intercoolers improve engine efficiency and reduce emissions for marine and land-based stationary engines.

Exhaust gas heat exchangers are designed to recover waste heat energy from the exhaust stream of reciprocating engine powered generating sets.

Bowman 'copper free' fuel coolers are compact, highly efficient heat exchangers suitable for fuel conditioning rigs in the automotive testing industry.

Engine coolant header tank heat exchangers for marine propulsion, gensets or stationary land-based engines.

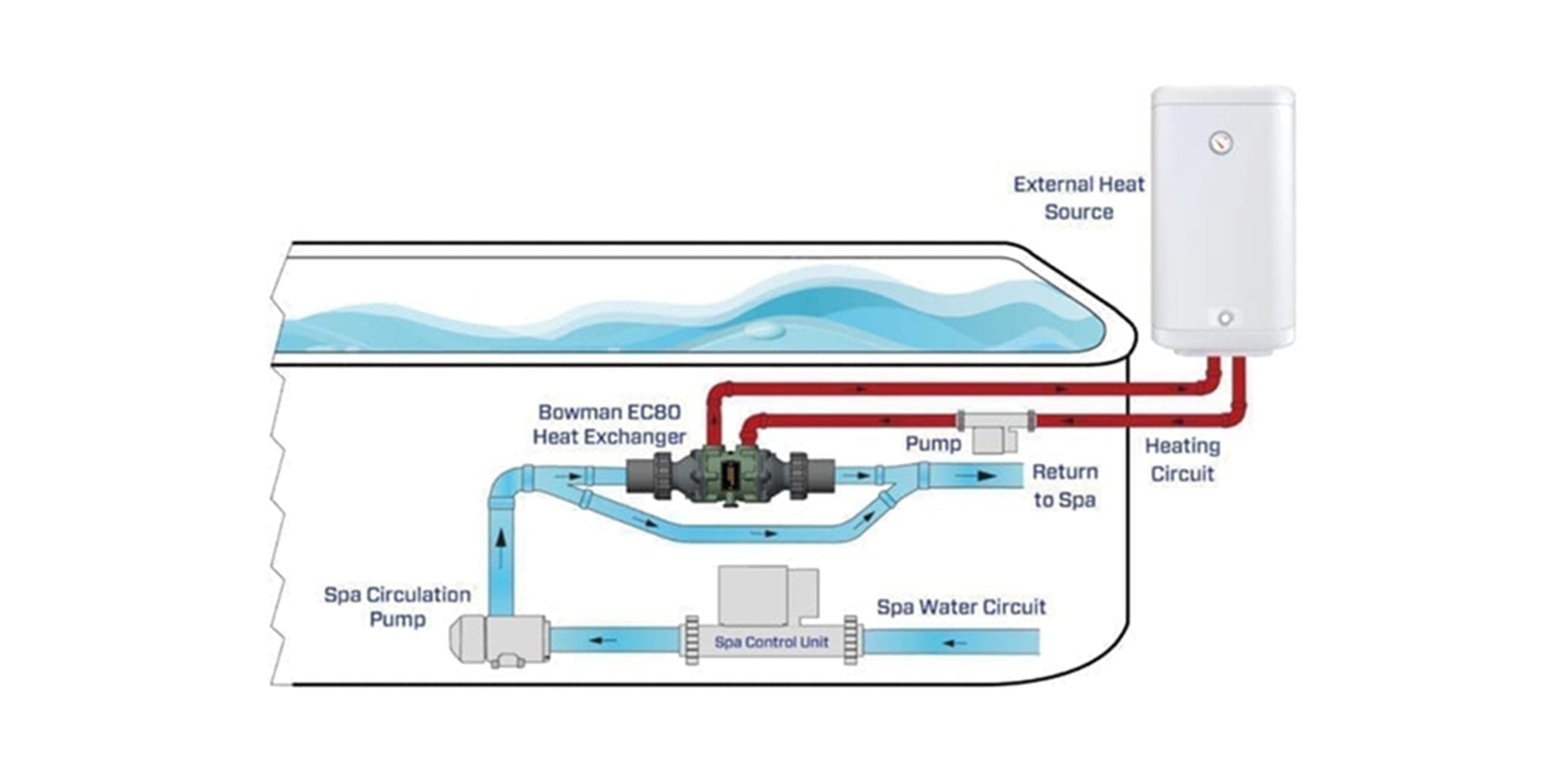

Bowman EC 80-5113-1T heat exchangers provide a new solution for heating spas and hot tubs in just a fraction of the time taken by traditional electric heaters.

Highly efficient heat transfer solutions for cooling marine, land-based and underground hydraulic systems.

Bowman inline plate heat exchangers are a compact, economical solution for high efficiency heat transfer.

Bespoke cooling solutions for a range of popular marine engines from major OEMs, including coolant heat exchangers, charge air coolers, plus combined heat exchangers and exhaust manifolds, suitable for cooling marine engines up to 1 MW.

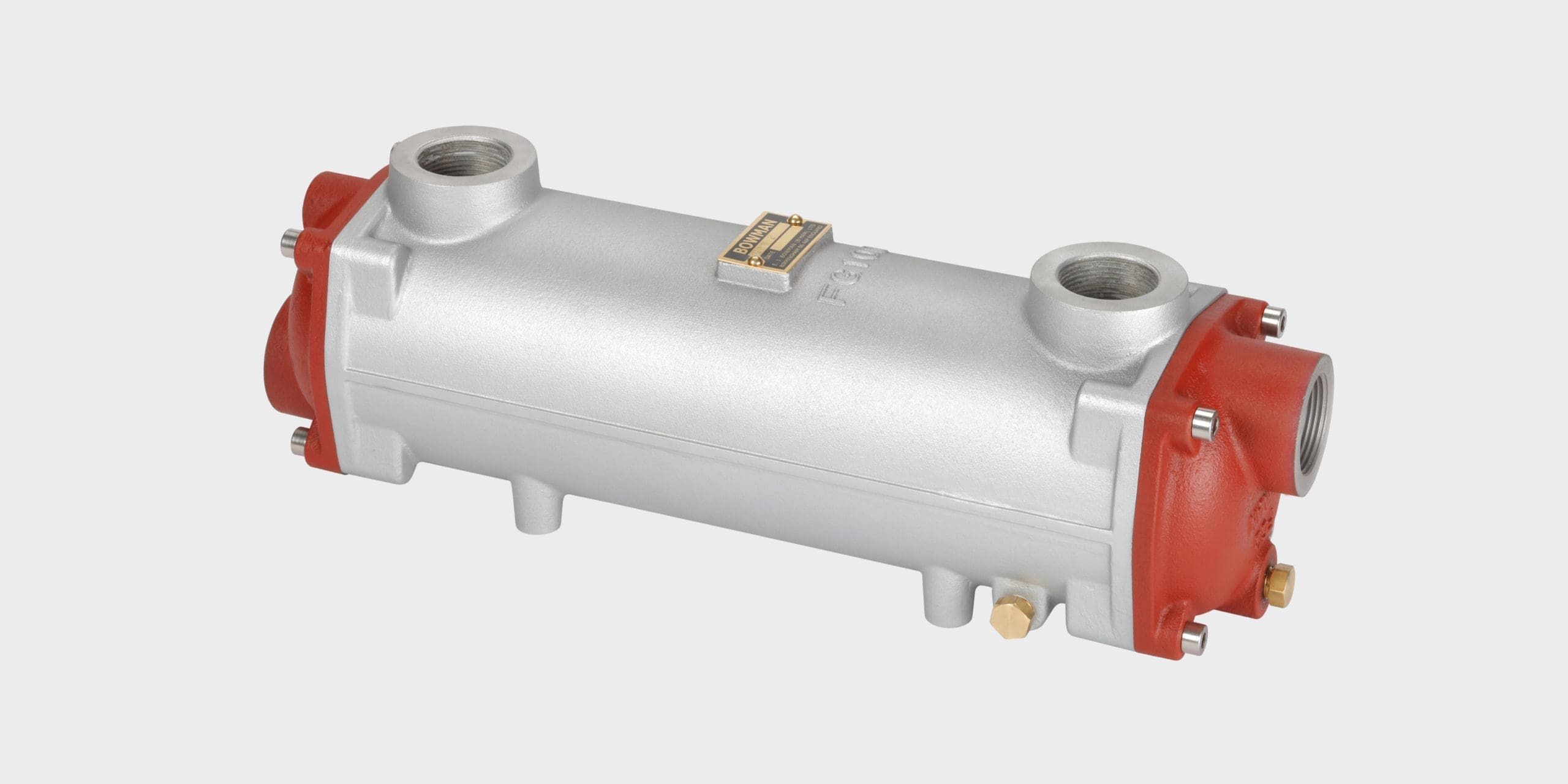

Bowman has a range of highly efficient oil coolers designed for marine and industrial engines and transmissions.

Efficient heat exchangers for cooling electric marine motors, hydrogen fuel cells, battery packs, chargers, AC-DC converters, DC-DC converters, inverters and associated equipment for electric and hybrid marine propulsion and charging systems.

Highly efficient heat transfer solutions for cooling a variety of applications where air and fluids need to be cooled by fluids.

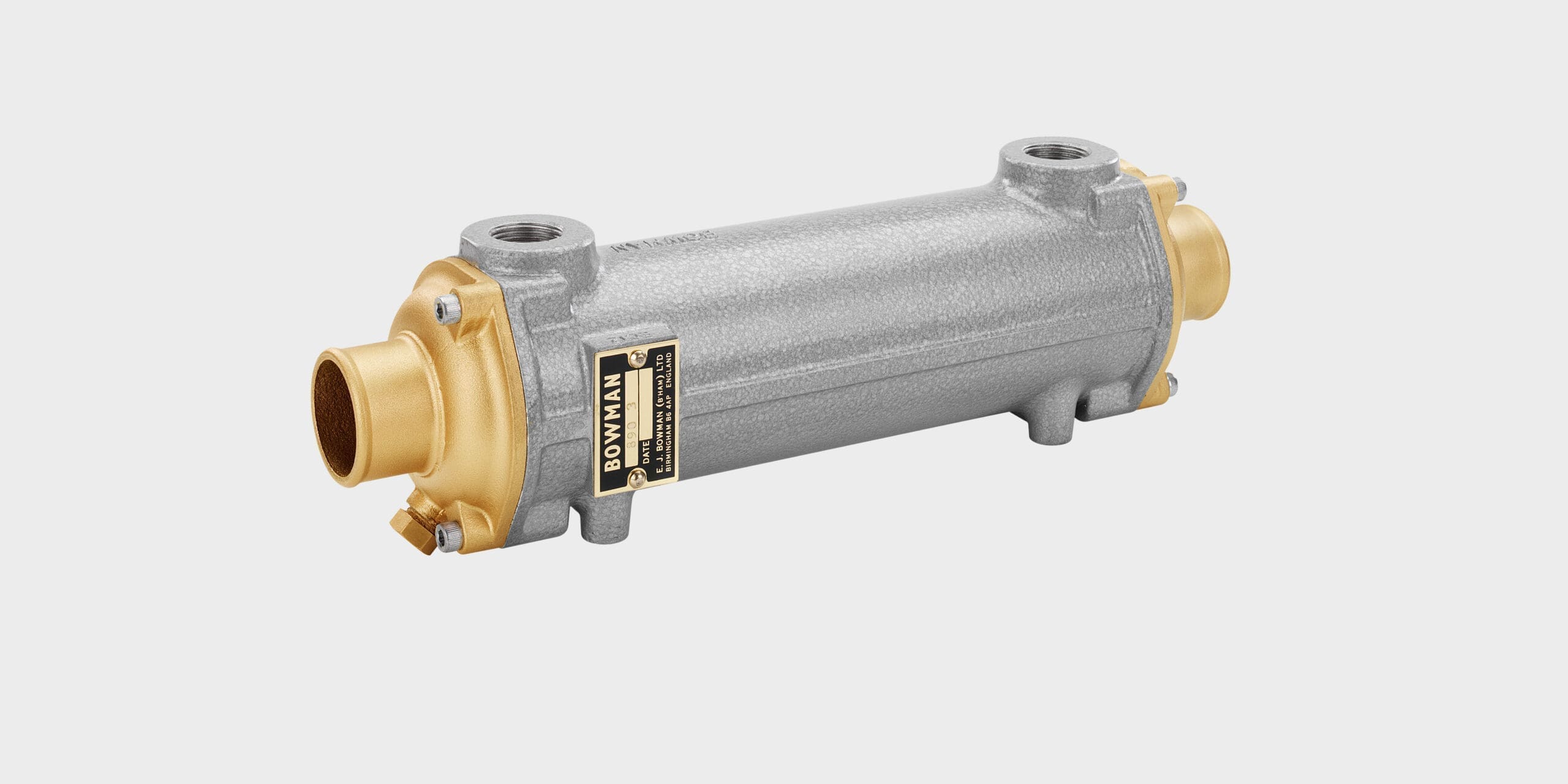

Many applications require stainless steel shell and tube heat exchangers and Bowman provide a standard range of units that are suitable for cooling or heating a variety of fluids.

Bowman swimming pool heat exchangers are renowned for reliability and efficiency. Whether heating your pool with a traditional boiler or a renewable energy source, Bowman is the obvious choice.

Premium quality heat exchangers and oil coolers for precise temperature control of engines under test cell development conditions.

Recovering waste heat energy from engine powered generating sets for biogas, diesel and natural gas applications up to 1 MW.

Efficient cooling for stationary / land-based engines where air cooling is either unavailable or inappropriate.

The reliable solution for cooling Electric & Hybrid Marine Propulsion Systems.

A comprehensive oil cooling solution for industrial hydraulic control systems, plus high temperature and mining applications.

A complete solution for cooling complex on-board hydraulic equipment, including thruster and stabiliser systems.

The complete cooling solution for marine engine propulsion, including the latest electric and hybrid systems.

An energy efficient solution for heating hot tubs and swim spas faster, significantly reducing heat-up time for guest change-over periods.

Quality heat exchangers for efficient swimming pool heating, using boiler or renewable energy heat sources.

How switching from electric heating, to a biomass system, reduced hot tub heat-up times to just 2-3 hours and reduced energy costs by £12,000 per year for this prestige Yorkshire resort.

The KP Club is a prestige golf and leisure resort, set in 180 acres of the Yorkshire Wolds. The club recently opened 24 new luxury woodland lodges, which offer its guests privacy, combined with the facilities of a boutique hotel. Each of the lodges has its own hot tub, supplied by Urban Cedar, who specialise in the design, build and installation of contemporary cedar wood hot tubs.

When the KP Club approached Urban Cedar to investigate a greener way of heating the hot tubs, they approached E J Bowman for advice. As a result, an innovative new heating solution, using Bowman heat exchangers, linked to the KP Club’s centralised Biomass heating system, has helped the club substantially reduce energy costs, by using this sustainable heating system in place of conventional electric heaters.

The solution

Urban Cedar contacted Bowman because of its reputation for producing the most thermally efficient swimming pool heat exchangers available. Bowman EC100-5113-2S stainless steel heat exchangers were recommended for the application and samples sent for Urban Cedar to test at its USA manufacturing facility. The units not only passed, but produced remarkable improvements in heat-up times and thermal efficiency compared to previously used electric heaters.

Back in the UK, Urban Cedar fitted the hot tubs with the Bowman units – a simple process requiring just standard plumbing components. The compact heat exchanger is hidden behind the skin of the hot tub, so, is neither visible nor affects the design.

The energy savings of the new system are nothing short of remarkable. On average, using conventional electric heaters, each hot tub would cost around £500 annually in electricity. However, by using Bowman heat exchangers linked to the main biomass boiler system, the hot tubs are now heated at no extra cost – saving the KP Club approximately £12,000 a year.

Another major benefit of the system is that the electric heaters typically raised the water temperature by just 1-2 °C an hour, taking up to 24 hours to heat a tub from cold. The Bowman heat exchangers raise the water temperature by 12 °C an hour – so the tub reaches temperature in just 2-3 hours, giving the hotel greater flexibility when servicing the tubs between guest changeovers and ensuring the tubs are ready immediately when new guests arrive.

“The KP Club is leading the way by using Bowman heat exchangers linked to a biomass boiler to heat its hot tubs. This is the first time we have come across this method and it offers huge potential to commercial, leisure and domestic hot tubs users,” says Antony Perry, Managing Director of Urban Cedar.

“Bowman heat exchangers, used in conjunction with the biomass boiler, create the opportunity to significantly reduce hot tub heating costs, by using a more energy-efficient and sustainable method of heating,” adds Antony Perry.

How switching from electric heating, to a biomass system, reduced hot tub heat-up times to just 2-3 hours and reduced energy costs by £12,000 per year for this prestige Yorkshire resort.

The KP Club is a prestige golf and leisure resort, set in 180 acres of the Yorkshire Wolds. The club recently opened 24 new luxury woodland lodges, which offer its guests privacy, combined with the facilities of a boutique hotel. Each of the lodges has its own hot tub, supplied by Urban Cedar, who specialise in the design, build and installation of contemporary cedar wood hot tubs.

When the KP Club approached Urban Cedar to investigate a greener way of heating the hot tubs, they approached E J Bowman for advice. As a result, an innovative new heating solution, using Bowman heat exchangers, linked to the KP Club’s centralised Biomass heating system, has helped the club substantially reduce energy costs, by using this sustainable heating system in place of conventional electric heaters.

The solution

Urban Cedar contacted Bowman because of its reputation for producing the most thermally efficient swimming pool heat exchangers available. Bowman EC100-5113-2S stainless steel heat exchangers were recommended for the application and samples sent for Urban Cedar to test at its USA manufacturing facility. The units not only passed, but produced remarkable improvements in heat-up times and thermal efficiency compared to previously used electric heaters.

Back in the UK, Urban Cedar fitted the hot tubs with the Bowman units – a simple process requiring just standard plumbing components. The compact heat exchanger is hidden behind the skin of the hot tub, so, is neither visible nor affects the design.

The energy savings of the new system are nothing short of remarkable. On average, using conventional electric heaters, each hot tub would cost around £500 annually in electricity. However, by using Bowman heat exchangers linked to the main biomass boiler system, the hot tubs are now heated at no extra cost – saving the KP Club approximately £12,000 a year.

Another major benefit of the system is that the electric heaters typically raised the water temperature by just 1-2 °C an hour, taking up to 24 hours to heat a tub from cold. The Bowman heat exchangers raise the water temperature by 12 °C an hour – so the tub reaches temperature in just 2-3 hours, giving the hotel greater flexibility when servicing the tubs between guest changeovers and ensuring the tubs are ready immediately when new guests arrive.

“The KP Club is leading the way by using Bowman heat exchangers linked to a biomass boiler to heat its hot tubs. This is the first time we have come across this method and it offers huge potential to commercial, leisure and domestic hot tubs users,” says Antony Perry, Managing Director of Urban Cedar.

“Bowman heat exchangers, used in conjunction with the biomass boiler, create the opportunity to significantly reduce hot tub heating costs, by using a more energy-efficient and sustainable method of heating,” adds Antony Perry.

More News from EJ Bowman

Bowman and Rinnai provide the perfect heating solution for an Australian roof top pool – where winter temperatures can be surprisingly cool!

Six Bowman heat exchangers have been installed at the recently opened Gold’s Gym, Amman, Jordan, to heat two half Olympic-sized swimming pools.

How Bowman heat exchangers are helping this internationally renowned golf destination reduce energy costs and CO₂ emissions.

Bowman heat exchangers are playing an important role in the success of a flagship hotel on the Black Sea coast in Georgia.

Bowman and Rinnai provide the perfect heating solution for an Australian roof top pool – where winter temperatures can be surprisingly cool!

Six Bowman heat exchangers have been installed at the recently opened Gold’s Gym, Amman, Jordan, to heat two half Olympic-sized swimming pools.

How Bowman heat exchangers are helping this internationally renowned golf destination reduce energy costs and CO₂ emissions.

Bowman heat exchangers are playing an important role in the success of a flagship hotel on the Black Sea coast in Georgia.