Rooftop swimming pool heating in Perth, WA

Bowman and Rinnai provide the perfect heating solution for an Australian roof top pool – where winter temperatures can be surprisingly cool!

Used to cool the hot, compressed air from the turbo before it reaches the engine, the intercoolers improve engine efficiency and reduce emissions for marine and land-based stationary engines.

Exhaust gas heat exchangers are designed to recover waste heat energy from the exhaust stream of reciprocating engine powered generating sets.

Bowman 'copper free' fuel coolers are compact, highly efficient heat exchangers suitable for fuel conditioning rigs in the automotive testing industry.

Engine coolant header tank heat exchangers for marine propulsion, gensets or stationary land-based engines.

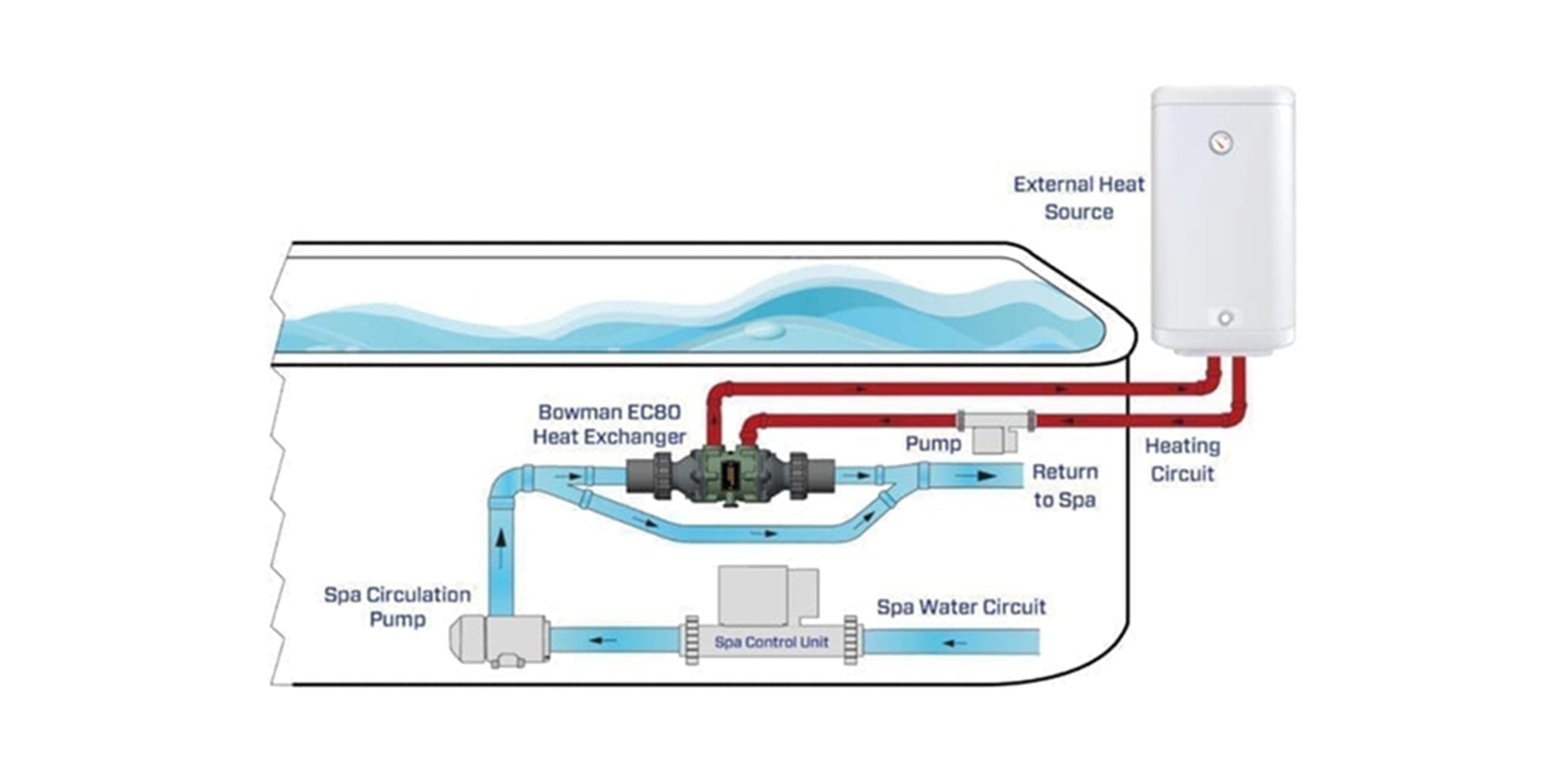

Bowman EC 80-5113-1T heat exchangers provide a new solution for heating spas and hot tubs in just a fraction of the time taken by traditional electric heaters.

Highly efficient heat transfer solutions for cooling marine, land-based and underground hydraulic systems.

Bowman inline plate heat exchangers are a compact, economical solution for high efficiency heat transfer.

Bespoke cooling solutions for a range of popular marine engines from major OEMs, including coolant heat exchangers, charge air coolers, plus combined heat exchangers and exhaust manifolds, suitable for cooling marine engines up to 1 MW.

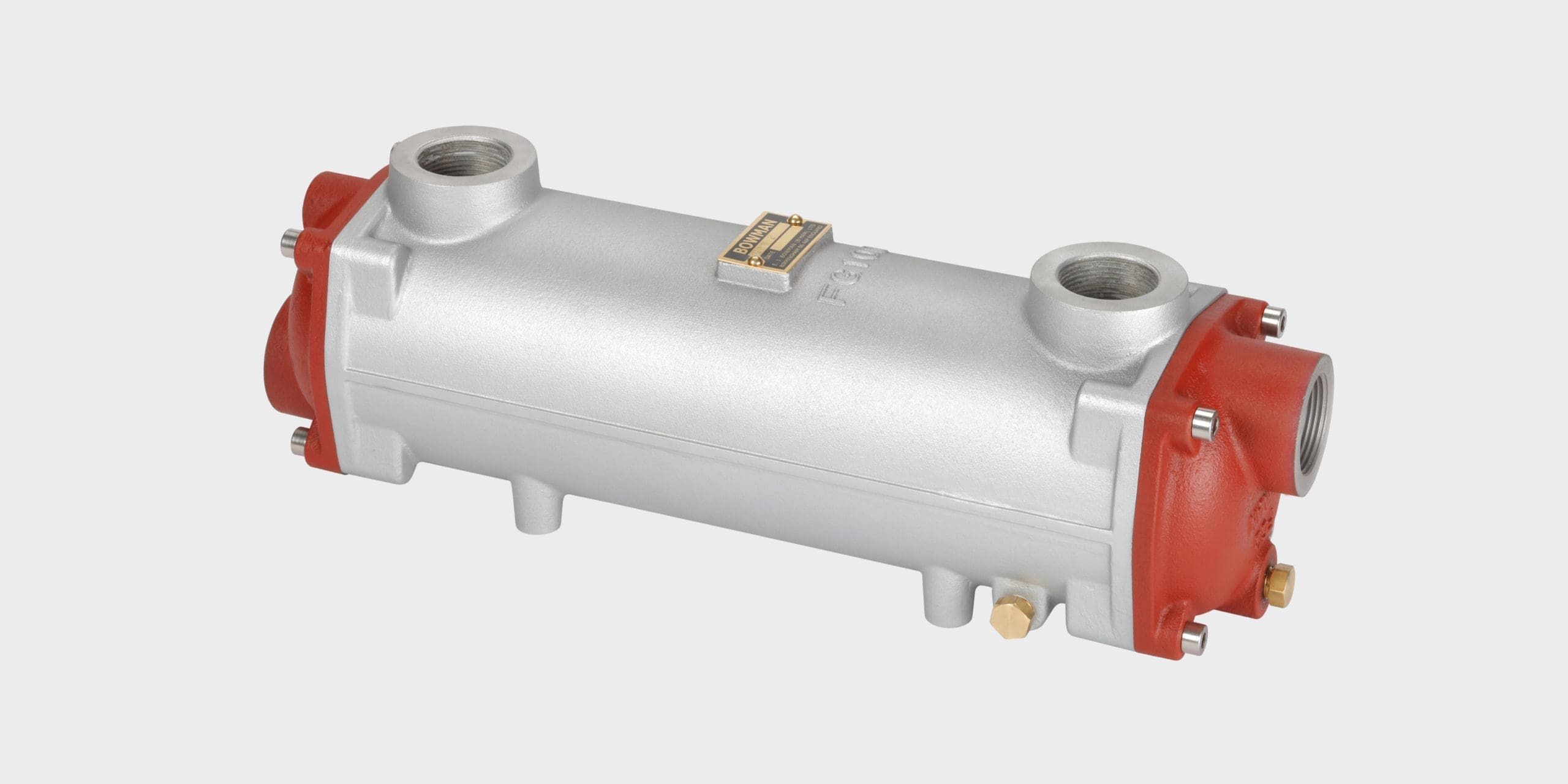

Bowman has a range of highly efficient oil coolers designed for marine and industrial engines and transmissions.

Efficient heat exchangers for cooling electric marine motors, hydrogen fuel cells, battery packs, chargers, AC-DC converters, DC-DC converters, inverters and associated equipment for electric and hybrid marine propulsion and charging systems.

Highly efficient heat transfer solutions for cooling a variety of applications where air and fluids need to be cooled by fluids.

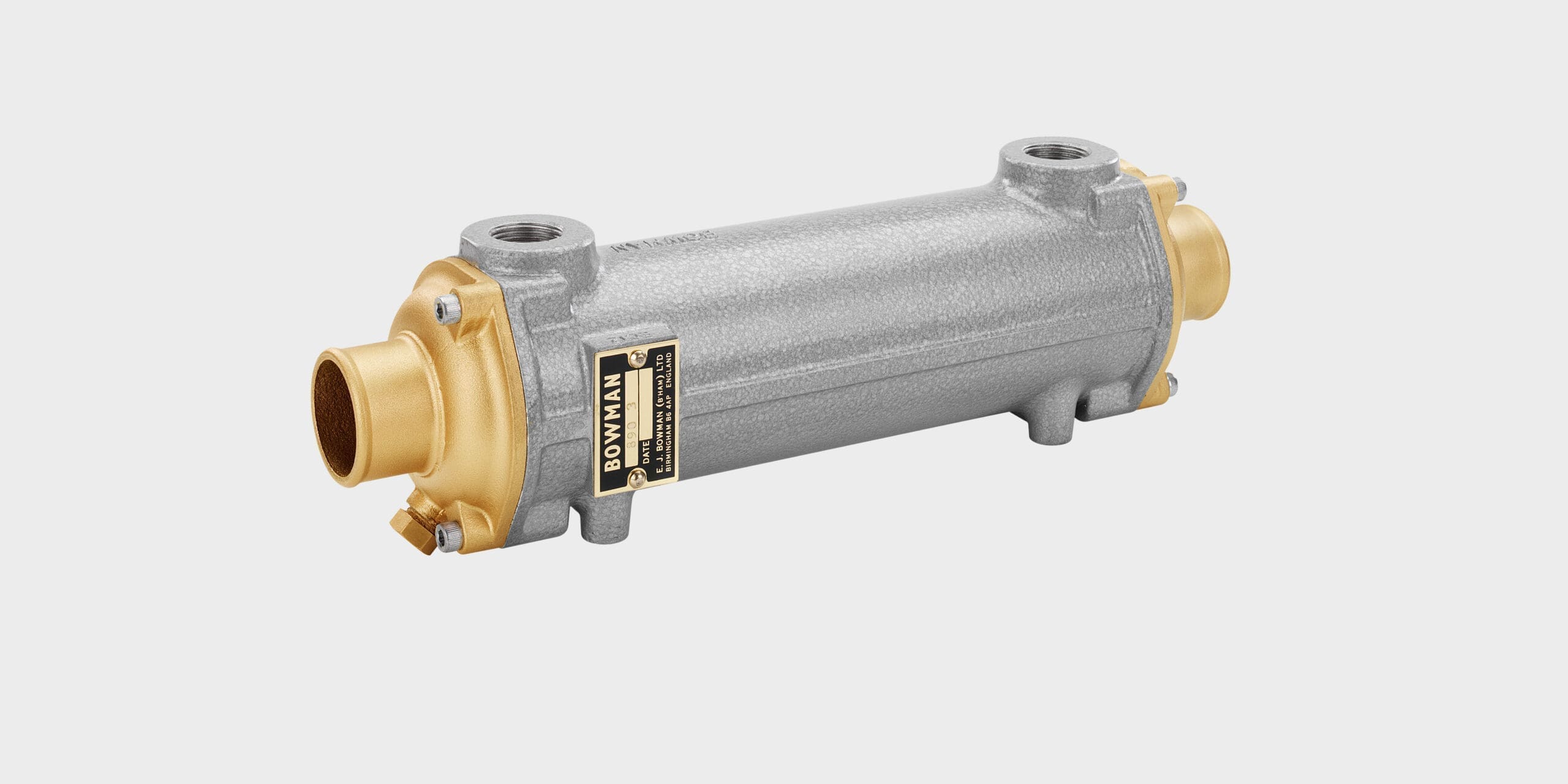

Many applications require stainless steel shell and tube heat exchangers and Bowman provide a standard range of units that are suitable for cooling or heating a variety of fluids.

Bowman swimming pool heat exchangers are renowned for reliability and efficiency. Whether heating your pool with a traditional boiler or a renewable energy source, Bowman is the obvious choice.

Premium quality heat exchangers and oil coolers for precise temperature control of engines under test cell development conditions.

Recovering waste heat energy from engine powered generating sets for biogas, diesel and natural gas applications up to 1 MW.

Efficient cooling for stationary / land-based engines where air cooling is either unavailable or inappropriate.

The reliable solution for cooling Electric & Hybrid Marine Propulsion Systems.

A comprehensive oil cooling solution for industrial hydraulic control systems, plus high temperature and mining applications.

A complete solution for cooling complex on-board hydraulic equipment, including thruster and stabiliser systems.

The complete cooling solution for marine engine propulsion, including the latest electric and hybrid systems.

An energy efficient solution for heating hot tubs and swim spas faster, significantly reducing heat-up time for guest change-over periods.

Quality heat exchangers for efficient swimming pool heating, using boiler or renewable energy heat sources.

Bowman publish a new brochure on cooling electric and hybrid marine propulsion systems.

In just a few years, electric and hybrid propulsion has gone from an industry in its infancy, to being adopted as a mainstream propulsion option by many sectors of the marine industry.

Whilst this increasing level of acceptance is often driven by emissions legislation in many parts of the world, there are also numerous operational benefits beyond the obvious environmental issues.

For example, water taxis and other watercraft used on lakes or inland waterways, not only benefit from reduced CO2 emissions, but also reduced noise pollution, too. Likewise, in sport fishing, where full power is required to get out to the fishing grounds, but very low power is used during fishing operations such as ‘trolling’, with a hybrid system, power can be switched from the main engine to electric propulsion, enabling the vessel to be operated much more efficiently.

As the industry has developed, it’s encouraging to see that many early electric or hybrid propulsion concepts have now become reality, as demand for these products gathers momentum.

However, one issue that remains key to its success is cooling.

It is estimated that 70% of all vessels will require cooling for the electric motor and perhaps all vessels will require cooling for the batteries and associated electrical control equipment.

The importance of cooling electrical components cannot be overemphasised as a universal principle of electronics states that a 10 °C (50 °F) lower temperature will double the life expectancy of an electrical component.

During the ‘Electric & Hybrid Propulsion World Expo’ in June 2019, the level of interest in cooling was very high and throughout the show, Bowman’s stand was kept busy with visitors looking for advice on cooling not only the electric motors and battery packs, but also the ancillary equipment, including AC-DC converters, DC-DC converters, on-board chargers, plus hybrid control units, combined electric motor/generator and engine-powered generators.

This has led Bowman to produce a new technical brochure covering its range of shell and tube heat exchangers for cooling electric and hybrid systems. With over 40 heat exchangers listed in the brochure, offering heat dissipation from 3 kW up to 701 kW, this is one of the most comprehensive ranges currently available. In addition to giving performance, specification and dimensional details, the brochure also provides information on Bowman’s own computer-aided product selection, which enables the company to recommend the most appropriate heat exchanger for a customer’s requirements.

With over 80 years’ experience of providing efficient heat exchangers to the marine industry, Bowman is ideally placed to recommend the most effective cooling solutions for electric or hybrid propulsion systems.

Copies of the brochure are freely available and can either be downloaded from ej-bowman.com or if a printed copy is preferred, by contacting Bowman directly on +44 (0)121 359 5401, or emailing [email protected].

Bowman publish a new brochure on cooling electric and hybrid marine propulsion systems.

In just a few years, electric and hybrid propulsion has gone from an industry in its infancy, to being adopted as a mainstream propulsion option by many sectors of the marine industry.

Whilst this increasing level of acceptance is often driven by emissions legislation in many parts of the world, there are also numerous operational benefits beyond the obvious environmental issues.

For example, water taxis and other watercraft used on lakes or inland waterways, not only benefit from reduced CO2 emissions, but also reduced noise pollution, too. Likewise, in sport fishing, where full power is required to get out to the fishing grounds, but very low power is used during fishing operations such as ‘trolling’, with a hybrid system, power can be switched from the main engine to electric propulsion, enabling the vessel to be operated much more efficiently.

As the industry has developed, it’s encouraging to see that many early electric or hybrid propulsion concepts have now become reality, as demand for these products gathers momentum.

However, one issue that remains key to its success is cooling.

It is estimated that 70% of all vessels will require cooling for the electric motor and perhaps all vessels will require cooling for the batteries and associated electrical control equipment.

The importance of cooling electrical components cannot be overemphasised as a universal principle of electronics states that a 10 °C (50 °F) lower temperature will double the life expectancy of an electrical component.

During the ‘Electric & Hybrid Propulsion World Expo’ in June 2019, the level of interest in cooling was very high and throughout the show, Bowman’s stand was kept busy with visitors looking for advice on cooling not only the electric motors and battery packs, but also the ancillary equipment, including AC-DC converters, DC-DC converters, on-board chargers, plus hybrid control units, combined electric motor/generator and engine-powered generators.

This has led Bowman to produce a new technical brochure covering its range of shell and tube heat exchangers for cooling electric and hybrid systems. With over 40 heat exchangers listed in the brochure, offering heat dissipation from 3 kW up to 701 kW, this is one of the most comprehensive ranges currently available. In addition to giving performance, specification and dimensional details, the brochure also provides information on Bowman’s own computer-aided product selection, which enables the company to recommend the most appropriate heat exchanger for a customer’s requirements.

With over 80 years’ experience of providing efficient heat exchangers to the marine industry, Bowman is ideally placed to recommend the most effective cooling solutions for electric or hybrid propulsion systems.

Copies of the brochure are freely available and can either be downloaded from ej-bowman.com or if a printed copy is preferred, by contacting Bowman directly on +44 (0)121 359 5401, or emailing [email protected].

More News from EJ Bowman

Bowman and Rinnai provide the perfect heating solution for an Australian roof top pool – where winter temperatures can be surprisingly cool!

Six Bowman heat exchangers have been installed at the recently opened Gold’s Gym, Amman, Jordan, to heat two half Olympic-sized swimming pools.

How Bowman heat exchangers are helping this internationally renowned golf destination reduce energy costs and CO₂ emissions.

Bowman heat exchangers are playing an important role in the success of a flagship hotel on the Black Sea coast in Georgia.

Bowman and Rinnai provide the perfect heating solution for an Australian roof top pool – where winter temperatures can be surprisingly cool!

Six Bowman heat exchangers have been installed at the recently opened Gold’s Gym, Amman, Jordan, to heat two half Olympic-sized swimming pools.

How Bowman heat exchangers are helping this internationally renowned golf destination reduce energy costs and CO₂ emissions.

Bowman heat exchangers are playing an important role in the success of a flagship hotel on the Black Sea coast in Georgia.