Rooftop swimming pool heating in Perth, WA

Bowman and Rinnai provide the perfect heating solution for an Australian roof top pool – where winter temperatures can be surprisingly cool!

Used to cool the hot, compressed air from the turbo before it reaches the engine, the intercoolers improve engine efficiency and reduce emissions for marine and land-based stationary engines.

Exhaust gas heat exchangers are designed to recover waste heat energy from the exhaust stream of reciprocating engine powered generating sets.

Bowman 'copper free' fuel coolers are compact, highly efficient heat exchangers suitable for fuel conditioning rigs in the automotive testing industry.

Engine coolant header tank heat exchangers for marine propulsion, gensets or stationary land-based engines.

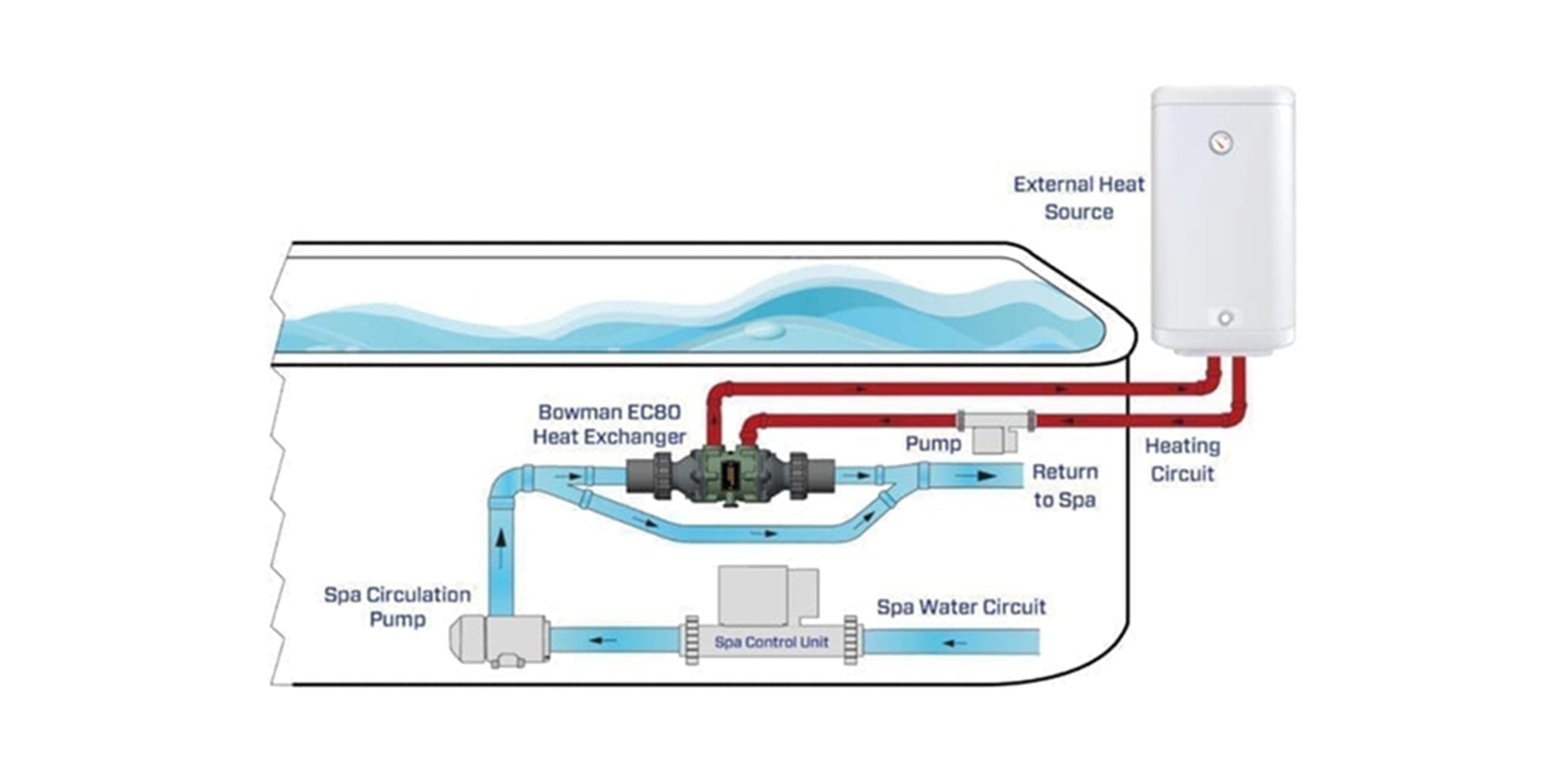

Bowman EC 80-5113-1T heat exchangers provide a new solution for heating spas and hot tubs in just a fraction of the time taken by traditional electric heaters.

Highly efficient heat transfer solutions for cooling marine, land-based and underground hydraulic systems.

Bowman inline plate heat exchangers are a compact, economical solution for high efficiency heat transfer.

Bespoke cooling solutions for a range of popular marine engines from major OEMs, including coolant heat exchangers, charge air coolers, plus combined heat exchangers and exhaust manifolds, suitable for cooling marine engines up to 1 MW.

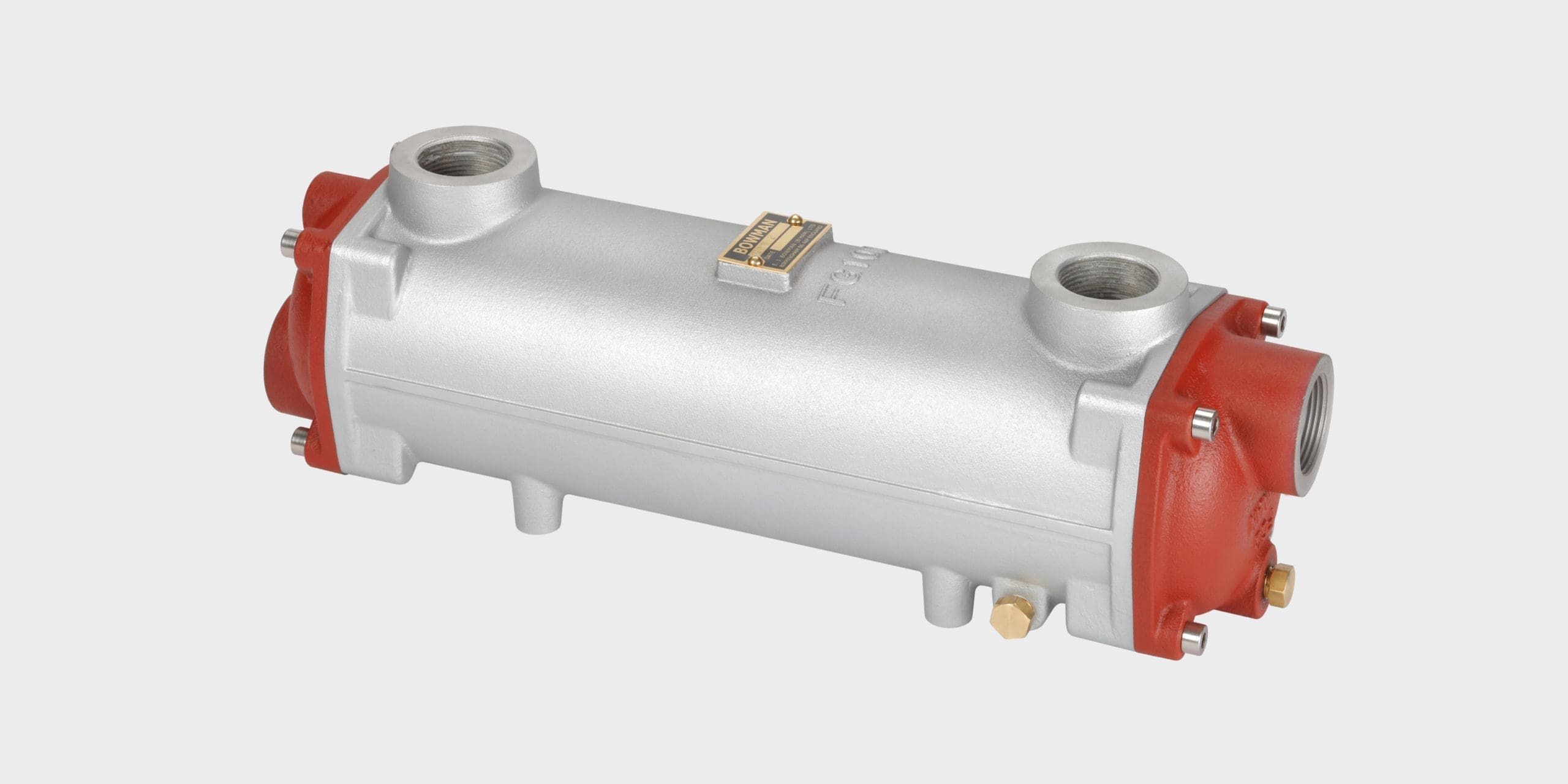

Bowman has a range of highly efficient oil coolers designed for marine and industrial engines and transmissions.

Efficient heat exchangers for cooling electric marine motors, hydrogen fuel cells, battery packs, chargers, AC-DC converters, DC-DC converters, inverters and associated equipment for electric and hybrid marine propulsion and charging systems.

Highly efficient heat transfer solutions for cooling a variety of applications where air and fluids need to be cooled by fluids.

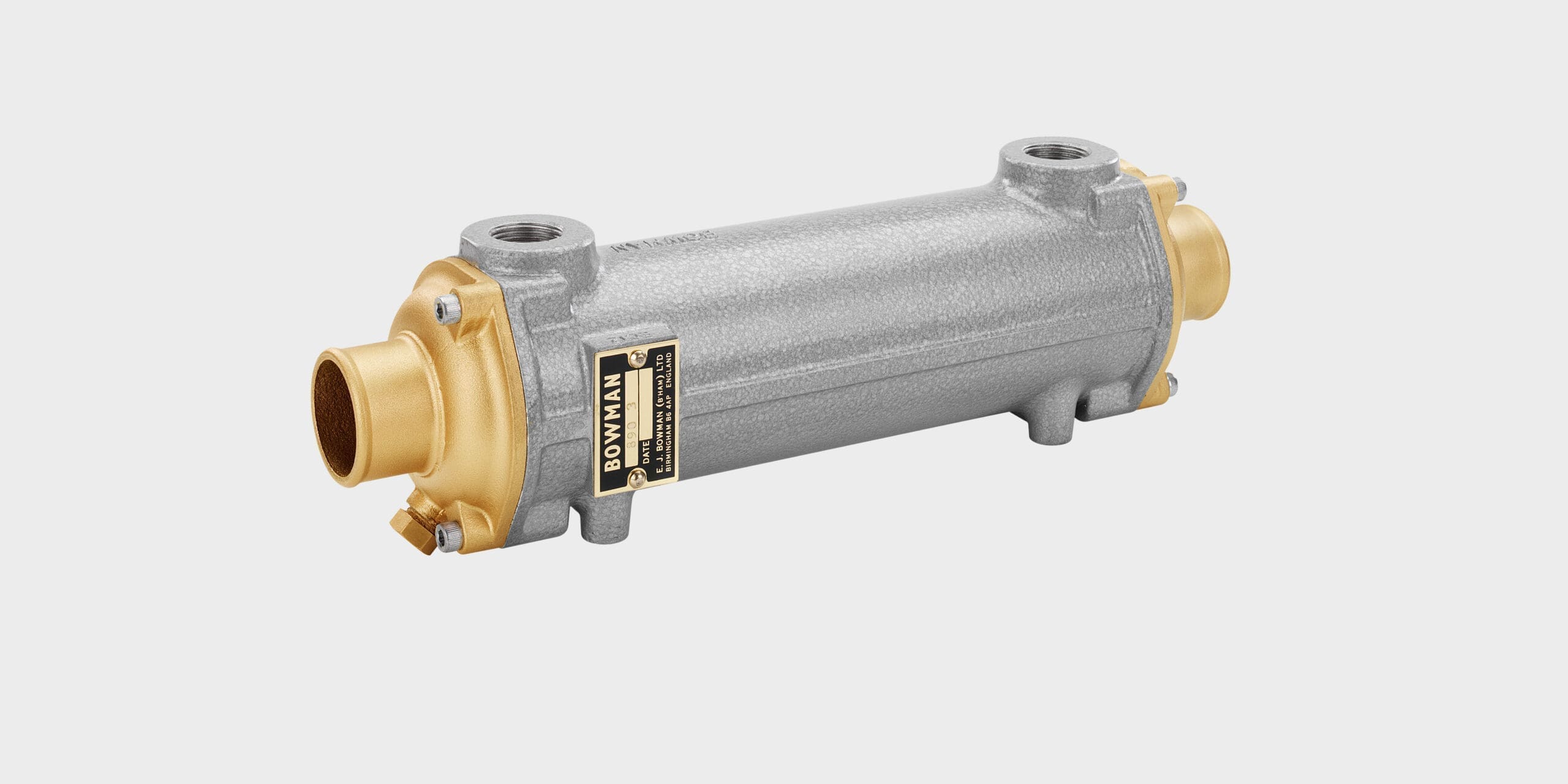

Many applications require stainless steel shell and tube heat exchangers and Bowman provide a standard range of units that are suitable for cooling or heating a variety of fluids.

Bowman swimming pool heat exchangers are renowned for reliability and efficiency. Whether heating your pool with a traditional boiler or a renewable energy source, Bowman is the obvious choice.

Premium quality heat exchangers and oil coolers for precise temperature control of engines under test cell development conditions.

Recovering waste heat energy from engine powered generating sets for biogas, diesel and natural gas applications up to 1 MW.

Efficient cooling for stationary / land-based engines where air cooling is either unavailable or inappropriate.

The reliable solution for cooling Electric & Hybrid Marine Propulsion Systems.

A comprehensive oil cooling solution for industrial hydraulic control systems, plus high temperature and mining applications.

A complete solution for cooling complex on-board hydraulic equipment, including thruster and stabiliser systems.

The complete cooling solution for marine engine propulsion, including the latest electric and hybrid systems.

An energy efficient solution for heating hot tubs and swim spas faster, significantly reducing heat-up time for guest change-over periods.

Quality heat exchangers for efficient swimming pool heating, using boiler or renewable energy heat sources.

In just a few years, electric and hybrid propulsion has gone from a niche market enterprise to a serious mainstream solution for marine propulsion systems.

Originally seen as an option for small leisure craft, its continued development is now providing systems that deliver over 100 kW of clean, emission-free power!

As propulsion systems develop, one constant issue is the need to keep the heat generated within operating parameters, to ensure its performance and eliminate system failure due to heat overload.

Areas requiring cooling can include the battery pack and on-board charger, AC-DC convertor, DC-DC convertor, the electric drive motor, transformers, invertors plus on-shore battery charging stations.

Although all systems require different levels of heat dissipation, there are general guidelines that can be applied to establish the typical size of the heat exchanger required.

For example, an electric motor will commonly lose 6% approximately of the rated power in the form of heat. Therefore, a 100 kW motor may need a unit capable of removing 6 kW of thermal energy. The associated components will typically require a further 3% of the motor’s power to be dissipated, whilst additional cooling may be required for the batteries.

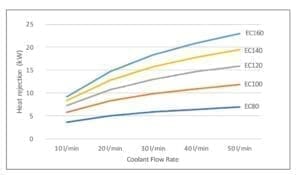

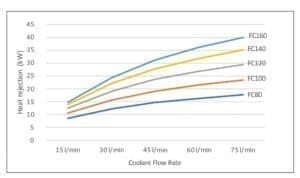

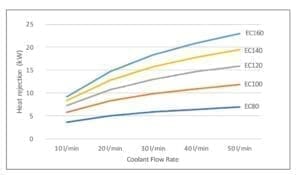

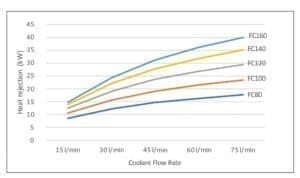

Coolant flow rates also affect the performance of a heat exchanger and usually vary from one electrical system to another. So, the 100 kW system example above would require at least 9 kW of heat rejection. The performance graphs below illustrate that if the coolant flow through the system is 40 l/min, a Bowman EC100 would be suitable for the job. However, if the coolant flow rate was only 15 l/min, a larger FC100 heat exchanger would be required, as a low coolant flow rate significantly reduces the cooling capability of any heat exchanger!

EC Series Heat Exchangers

FC Series Heat Exchangers

Figures based upon: Coolant type: 50/50 water/glycol. Sea water inlet temperature: 30 °C at 50 l/min. Coolant inlet temperature: 50 °C.

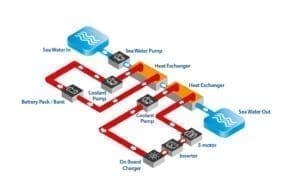

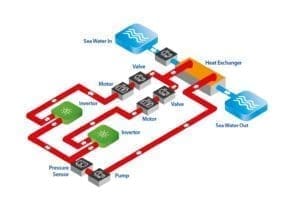

Bowman heat exchangers are easily integrated into the design of the propulsion system and a single unit is usually all that is required. However, in some installations, a secondary circuit may be required where components (such as the battery) have specific cooling requirements. The illustrations below show three typical scenarios for cooling electric and hybrid systems.

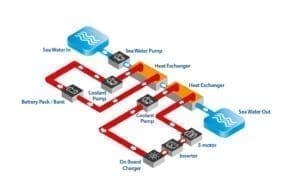

Two heat exchangers, installed in series, control the differing cooling requirements for the battery bank and invertor/drive circuits.

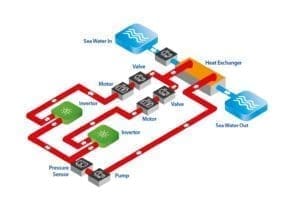

A single heat exchanger is used to cool the dual invertor/drive circuits in this installation.

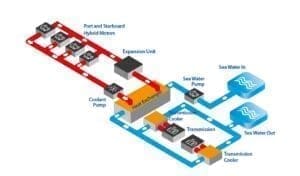

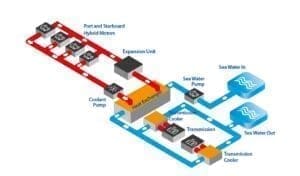

A single heat exchanger cools both the hybrid motors and invertors, plus two separate coolers installed within this hybrid system.

Electric and hybrid systems are often designed to operate with sea water temperatures of 30 °C plus, so selecting the right unit is critical to performance and reliability. However, by supplying the following information, Bowman can provide a computer-aided product selection, to recommend the most appropriate heat exchanger for an application:

Coolant type and concentration

Heat to be dissipated (in kW)

Required coolant outlet temperature (in °C)

Coolant flow (in l/min)

Sea water temperature (in °C)

For more information, contact the sales team on +44 (0)121 359 5401 or email [email protected].

In just a few years, electric and hybrid propulsion has gone from a niche market enterprise to a serious mainstream solution for marine propulsion systems.

Originally seen as an option for small leisure craft, its continued development is now providing systems that deliver over 100 kW of clean, emission-free power!

As propulsion systems develop, one constant issue is the need to keep the heat generated within operating parameters, to ensure its performance and eliminate system failure due to heat overload.

Areas requiring cooling can include the battery pack and on-board charger, AC-DC convertor, DC-DC convertor, the electric drive motor, transformers, invertors plus on-shore battery charging stations.

Although all systems require different levels of heat dissipation, there are general guidelines that can be applied to establish the typical size of the heat exchanger required.

For example, an electric motor will commonly lose 6% approximately of the rated power in the form of heat. Therefore, a 100 kW motor may need a unit capable of removing 6 kW of thermal energy. The associated components will typically require a further 3% of the motor’s power to be dissipated, whilst additional cooling may be required for the batteries.

Coolant flow rates also affect the performance of a heat exchanger and usually vary from one electrical system to another. So, the 100 kW system example above would require at least 9 kW of heat rejection. The performance graphs below illustrate that if the coolant flow through the system is 40 l/min, a Bowman EC100 would be suitable for the job. However, if the coolant flow rate was only 15 l/min, a larger FC100 heat exchanger would be required, as a low coolant flow rate significantly reduces the cooling capability of any heat exchanger!

EC Series Heat Exchangers

FC Series Heat Exchangers

Figures based upon: Coolant type: 50/50 water/glycol. Sea water inlet temperature: 30 °C at 50 l/min. Coolant inlet temperature: 50 °C.

Bowman heat exchangers are easily integrated into the design of the propulsion system and a single unit is usually all that is required. However, in some installations, a secondary circuit may be required where components (such as the battery) have specific cooling requirements. The illustrations below show three typical scenarios for cooling electric and hybrid systems.

Two heat exchangers, installed in series, control the differing cooling requirements for the battery bank and invertor/drive circuits.

A single heat exchanger is used to cool the dual invertor/drive circuits in this installation.

A single heat exchanger cools both the hybrid motors and invertors, plus two separate coolers installed within this hybrid system.

Electric and hybrid systems are often designed to operate with sea water temperatures of 30 °C plus, so selecting the right unit is critical to performance and reliability. However, by supplying the following information, Bowman can provide a computer-aided product selection, to recommend the most appropriate heat exchanger for an application:

Coolant type and concentration

Heat to be dissipated (in kW)

Required coolant outlet temperature (in °C)

Coolant flow (in l/min)

Sea water temperature (in °C)

For more information, contact the sales team on +44 (0)121 359 5401 or email [email protected].

Bowman and Rinnai provide the perfect heating solution for an Australian roof top pool – where winter temperatures can be surprisingly cool!

Six Bowman heat exchangers have been installed at the recently opened Gold’s Gym, Amman, Jordan, to heat two half Olympic-sized swimming pools.

How Bowman heat exchangers are helping this internationally renowned golf destination reduce energy costs and CO₂ emissions.

Bowman heat exchangers are playing an important role in the success of a flagship hotel on the Black Sea coast in Georgia.

Bowman and Rinnai provide the perfect heating solution for an Australian roof top pool – where winter temperatures can be surprisingly cool!

Six Bowman heat exchangers have been installed at the recently opened Gold’s Gym, Amman, Jordan, to heat two half Olympic-sized swimming pools.

How Bowman heat exchangers are helping this internationally renowned golf destination reduce energy costs and CO₂ emissions.

Bowman heat exchangers are playing an important role in the success of a flagship hotel on the Black Sea coast in Georgia.