Rooftop swimming pool heating in Perth, WA

Bowman and Rinnai provide the perfect heating solution for an Australian roof top pool – where winter temperatures can be surprisingly cool!

Used to cool the hot, compressed air from the turbo before it reaches the engine, the intercoolers improve engine efficiency and reduce emissions for marine and land-based stationary engines.

Exhaust gas heat exchangers are designed to recover waste heat energy from the exhaust stream of reciprocating engine powered generating sets.

Bowman 'copper free' fuel coolers are compact, highly efficient heat exchangers suitable for fuel conditioning rigs in the automotive testing industry.

Engine coolant header tank heat exchangers for marine propulsion, gensets or stationary land-based engines.

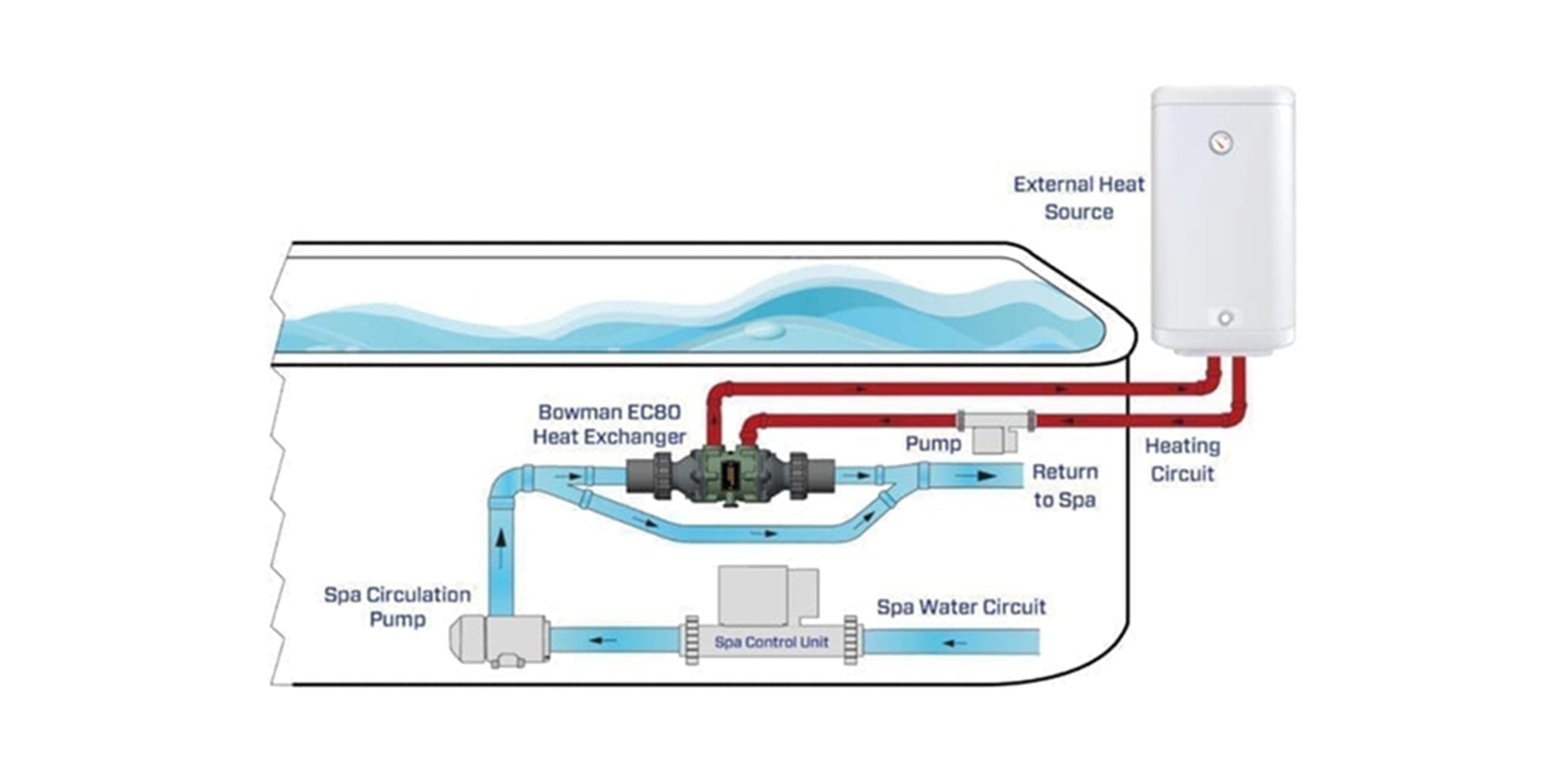

Bowman EC 80-5113-1T heat exchangers provide a new solution for heating spas and hot tubs in just a fraction of the time taken by traditional electric heaters.

Highly efficient heat transfer solutions for cooling marine, land-based and underground hydraulic systems.

Bowman inline plate heat exchangers are a compact, economical solution for high efficiency heat transfer.

Bespoke cooling solutions for a range of popular marine engines from major OEMs, including coolant heat exchangers, charge air coolers, plus combined heat exchangers and exhaust manifolds, suitable for cooling marine engines up to 1 MW.

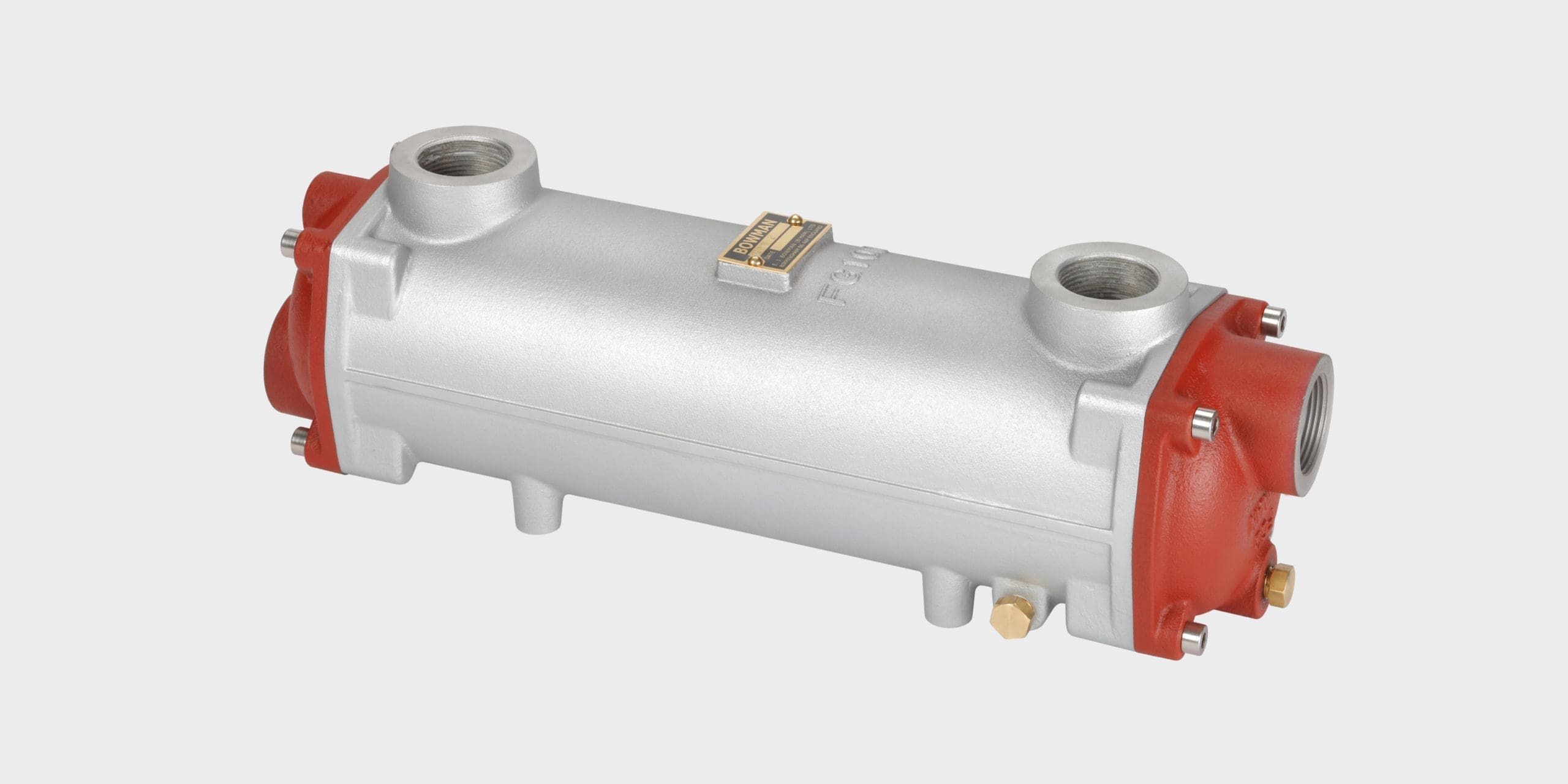

Bowman has a range of highly efficient oil coolers designed for marine and industrial engines and transmissions.

Efficient heat exchangers for cooling electric marine motors, hydrogen fuel cells, battery packs, chargers, AC-DC converters, DC-DC converters, inverters and associated equipment for electric and hybrid marine propulsion and charging systems.

Highly efficient heat transfer solutions for cooling a variety of applications where air and fluids need to be cooled by fluids.

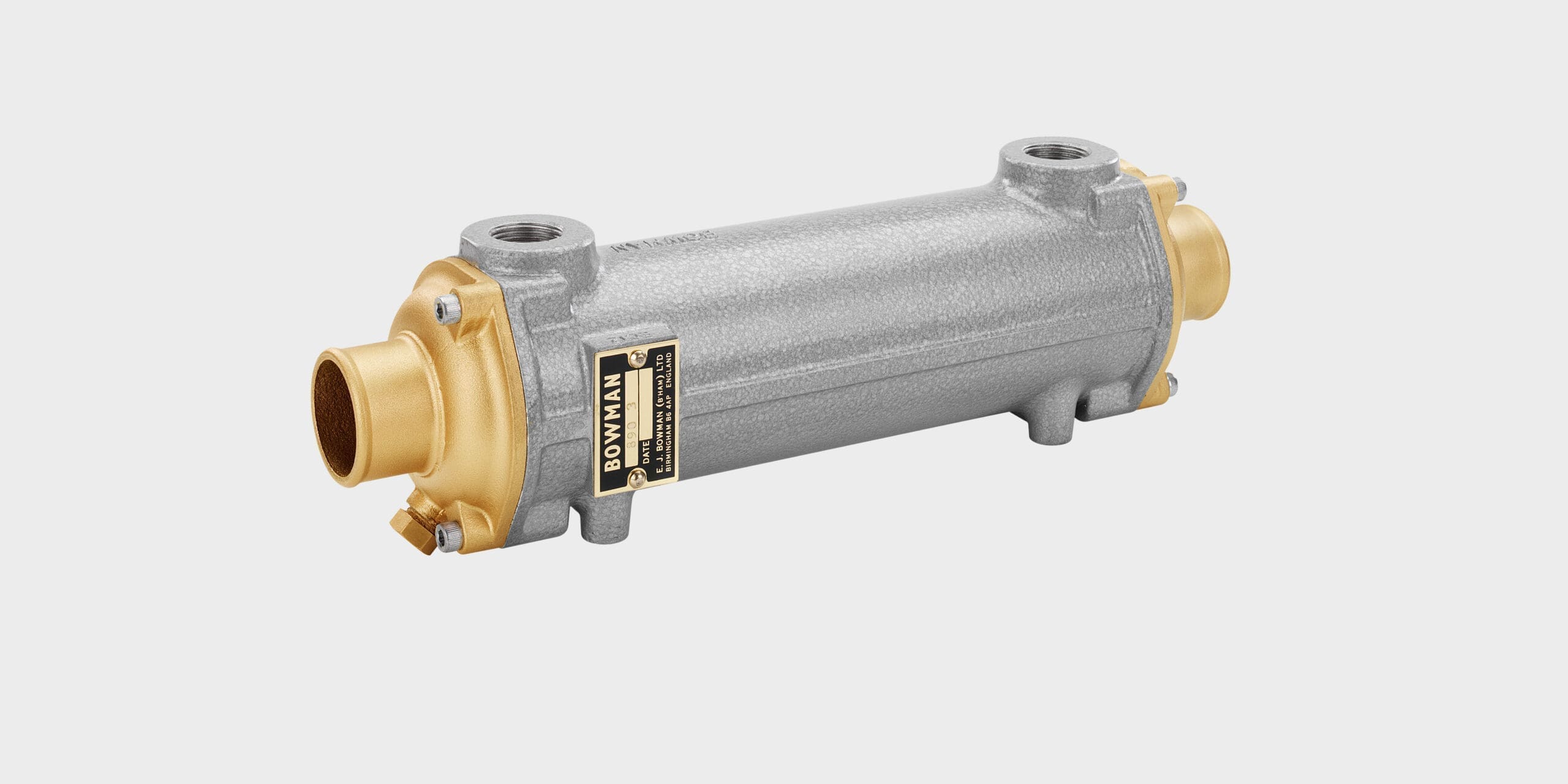

Many applications require stainless steel shell and tube heat exchangers and Bowman provide a standard range of units that are suitable for cooling or heating a variety of fluids.

Bowman swimming pool heat exchangers are renowned for reliability and efficiency. Whether heating your pool with a traditional boiler or a renewable energy source, Bowman is the obvious choice.

Premium quality heat exchangers and oil coolers for precise temperature control of engines under test cell development conditions.

Recovering waste heat energy from engine powered generating sets for biogas, diesel and natural gas applications up to 1 MW.

Efficient cooling for stationary / land-based engines where air cooling is either unavailable or inappropriate.

The reliable solution for cooling Electric & Hybrid Marine Propulsion Systems.

A comprehensive oil cooling solution for industrial hydraulic control systems, plus high temperature and mining applications.

A complete solution for cooling complex on-board hydraulic equipment, including thruster and stabiliser systems.

The complete cooling solution for marine engine propulsion, including the latest electric and hybrid systems.

An energy efficient solution for heating hot tubs and swim spas faster, significantly reducing heat-up time for guest change-over periods.

Quality heat exchangers for efficient swimming pool heating, using boiler or renewable energy heat sources.

Hydrogen fuel cells have enormous potential as a ‘zero emissions’ fuel for the marine industry, but correct system cooling is vitally important. Thankfully, Bowman has the solution!

The marine industry is ramping up towards a net carbon future and internationally has set ambitious targets, including reducing current CO2 emissions by 40% by 2030 and 70% by 2050.

Ambitious targets indeed, and the level of ‘green fuel’ development suggests they’re being taken seriously by the marine industry.

One energy solution gaining momentum is ‘clean hydrogen fuel cells’, which have been identified as a vital fuel to achieve the decarbonisation of marine transport.

Whilst battery-powered electric propulsion is extremely popular, for many marine applications it’s just not feasible – either due to range limitations, or the size of vessel. And this is where clean hydrogen fuel cells could be a game changer.

Clean hydrogen isn’t new, of course. It’s been used in industry for decades and is safe to produce, store and transport.

It’s also the most readily available element on earth and, as the only renewable fuel that’s completely free from CO2, it could be the ultimate clean fuel.

In fact, many industry observers are predicting an 800% rise in demand for clean hydrogen over the next 20 years!

So, is it really the marine industry’s ‘zero emission silver bullet’? There are many, who think it could be and here’s why:

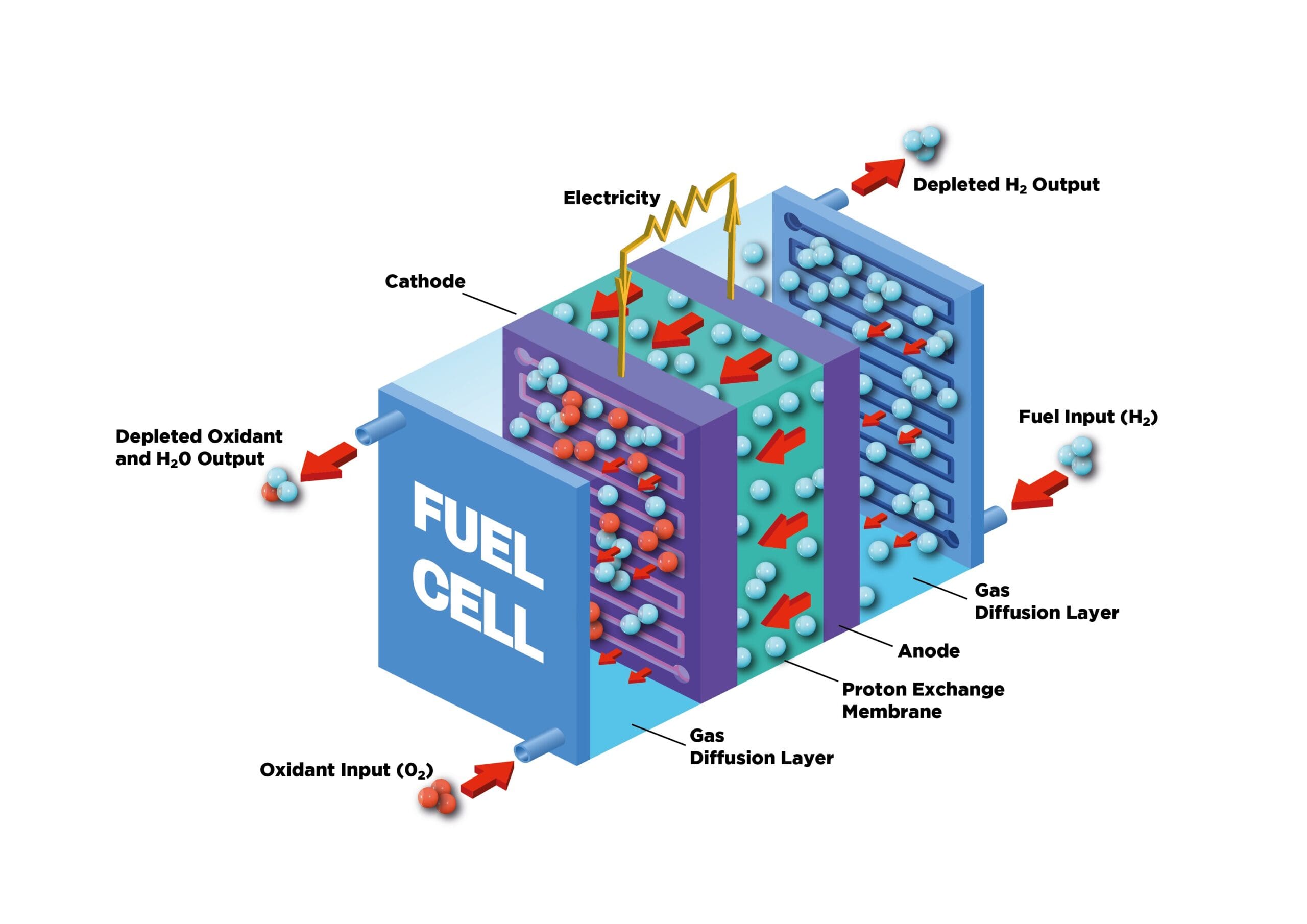

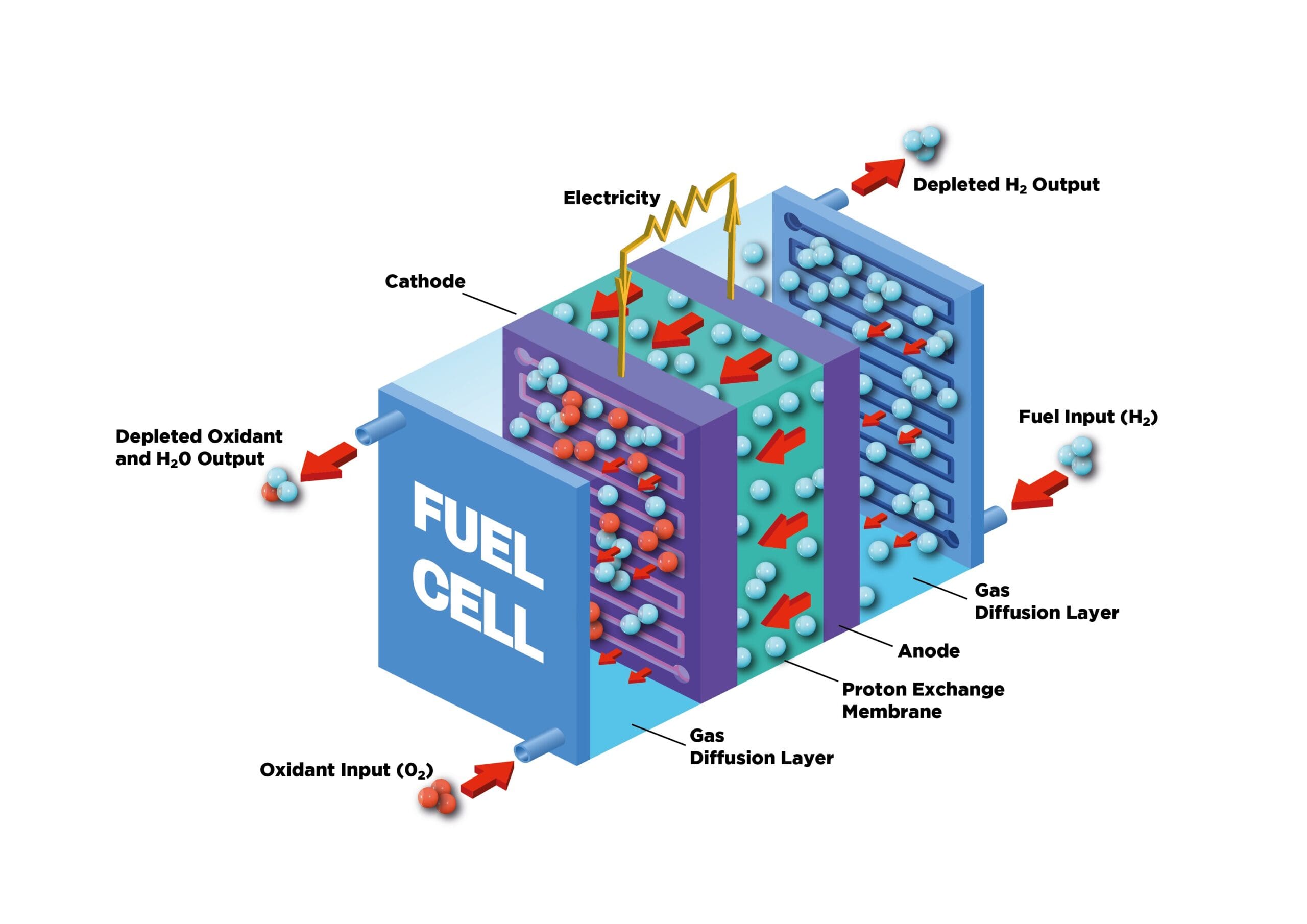

Fuel cells operate similar to batteries, creating an electrochemical reaction between the anode or cathode and the electrolyte membrane, but with continuous fuel and air supplies.

When the hydrogen comes into contact with the catalyst, it splits into protons and electrons; the protons passing through a ‘proton exchange membrane’ and on to the cathode side of the fuel cell.

When the hydrogen comes into contact with the catalyst, it splits into protons and electrons; the protons passing through a ‘proton exchange membrane’ and on to the cathode side of the fuel cell.

The electrons are blocked and forced to travel through an external circuit, which as they do, they create electricity, which can be used for battery recharging, or directly powering an electric motor.

Ultimately, the protons and electrons rejoin together and combine with oxygen, creating H2O, the totally harmless fluid we get out of our taps!

However, hydrogen fuel cells are expensive and protecting them from potential damage from external elements such as cooling water is critical! Using high-quality heat exchangers within the cooling system is extremely important.

This led Bowman to develop a range of titanium shell and tube units, to support the performance requirements of marine renewable energy applications, such as clean hydrogen.

Recently introduced, the Bowman range includes over 15 model variants, capable of dissipating between 3 kW and 65 kW of heat from the cooling circuit, providing a cost-effective titanium solution that is virtually impervious to corrosion.

UK manufactured, using titanium, aluminium and composite materials, these heat exchangers are also much lighter than traditional marine specification units, helping to reduce the overall weight of ancillary equipment.

Bowman also offer a range of larger titanium units, offering up to 700 kW of heat dissipation, for applications higher heat loads are generated.

Already the ‘go to brand’ for battery electric marine propulsion, Bowman heat exchangers proved their hydrogen cooling capabilities at the 2022 Monaco Energy Boat Challenge.

Here Bowman helped TU Delft Hydro Motion Team win the ‘Endurance Challenge’, a 6-hour race with no recharging or refuelling. Finishing 7 laps ahead of their nearest competitor, Hydro Motion achieved an amazing result, clearly demonstrating clean hydrogen’s potential for the marine industry.

Hydrogen fuel cells have enormous potential as a ‘zero emissions’ fuel for the marine industry, but correct system cooling is vitally important. Thankfully, Bowman has the solution!

The marine industry is ramping up towards a net carbon future and internationally has set ambitious targets, including reducing current CO2 emissions by 40% by 2030 and 70% by 2050.

Ambitious targets indeed, and the level of ‘green fuel’ development suggests they’re being taken seriously by the marine industry.

One energy solution gaining momentum is ‘clean hydrogen fuel cells’, which have been identified as a vital fuel to achieve the decarbonisation of marine transport.

Whilst battery-powered electric propulsion is extremely popular, for many marine applications it’s just not feasible – either due to range limitations, or the size of vessel. And this is where clean hydrogen fuel cells could be a game changer.

Clean hydrogen isn’t new, of course. It’s been used in industry for decades and is safe to produce, store and transport.

It’s also the most readily available element on earth and, as the only renewable fuel that’s completely free from CO2, it could be the ultimate clean fuel.

In fact, many industry observers are predicting an 800% rise in demand for clean hydrogen over the next 20 years!

So, is it really the marine industry’s ‘zero emission silver bullet’? There are many, who think it could be and here’s why:

Fuel cells operate similar to batteries, creating an electrochemical reaction between the anode or cathode and the electrolyte membrane, but with continuous fuel and air supplies.

When the hydrogen comes into contact with the catalyst, it splits into protons and electrons; the protons passing through a ‘proton exchange membrane’ and on to the cathode side of the fuel cell.

When the hydrogen comes into contact with the catalyst, it splits into protons and electrons; the protons passing through a ‘proton exchange membrane’ and on to the cathode side of the fuel cell.

The electrons are blocked and forced to travel through an external circuit, which as they do, they create electricity, which can be used for battery recharging, or directly powering an electric motor.

Ultimately, the protons and electrons rejoin together and combine with oxygen, creating H2O, the totally harmless fluid we get out of our taps!

However, hydrogen fuel cells are expensive and protecting them from potential damage from external elements such as cooling water is critical! Using high-quality heat exchangers within the cooling system is extremely important.

This led Bowman to develop a range of titanium shell and tube units, to support the performance requirements of marine renewable energy applications, such as clean hydrogen.

Recently introduced, the Bowman range includes over 15 model variants, capable of dissipating between 3 kW and 65 kW of heat from the cooling circuit, providing a cost-effective titanium solution that is virtually impervious to corrosion.

UK manufactured, using titanium, aluminium and composite materials, these heat exchangers are also much lighter than traditional marine specification units, helping to reduce the overall weight of ancillary equipment.

Bowman also offer a range of larger titanium units, offering up to 700 kW of heat dissipation, for applications higher heat loads are generated.

Already the ‘go to brand’ for battery electric marine propulsion, Bowman heat exchangers proved their hydrogen cooling capabilities at the 2022 Monaco Energy Boat Challenge.

Here Bowman helped TU Delft Hydro Motion Team win the ‘Endurance Challenge’, a 6-hour race with no recharging or refuelling. Finishing 7 laps ahead of their nearest competitor, Hydro Motion achieved an amazing result, clearly demonstrating clean hydrogen’s potential for the marine industry.

Bowman and Rinnai provide the perfect heating solution for an Australian roof top pool – where winter temperatures can be surprisingly cool!

Six Bowman heat exchangers have been installed at the recently opened Gold’s Gym, Amman, Jordan, to heat two half Olympic-sized swimming pools.

How Bowman heat exchangers are helping this internationally renowned golf destination reduce energy costs and CO₂ emissions.

Bowman heat exchangers are playing an important role in the success of a flagship hotel on the Black Sea coast in Georgia.

Bowman and Rinnai provide the perfect heating solution for an Australian roof top pool – where winter temperatures can be surprisingly cool!

Six Bowman heat exchangers have been installed at the recently opened Gold’s Gym, Amman, Jordan, to heat two half Olympic-sized swimming pools.

How Bowman heat exchangers are helping this internationally renowned golf destination reduce energy costs and CO₂ emissions.

Bowman heat exchangers are playing an important role in the success of a flagship hotel on the Black Sea coast in Georgia.