Rooftop swimming pool heating in Perth, WA

Bowman and Rinnai provide the perfect heating solution for an Australian roof top pool – where winter temperatures can be surprisingly cool!

Used to cool the hot, compressed air from the turbo before it reaches the engine, the intercoolers improve engine efficiency and reduce emissions for marine and land-based stationary engines.

Exhaust gas heat exchangers are designed to recover waste heat energy from the exhaust stream of reciprocating engine powered generating sets.

Bowman 'copper free' fuel coolers are compact, highly efficient heat exchangers suitable for fuel conditioning rigs in the automotive testing industry.

Engine coolant header tank heat exchangers for marine propulsion, gensets or stationary land-based engines.

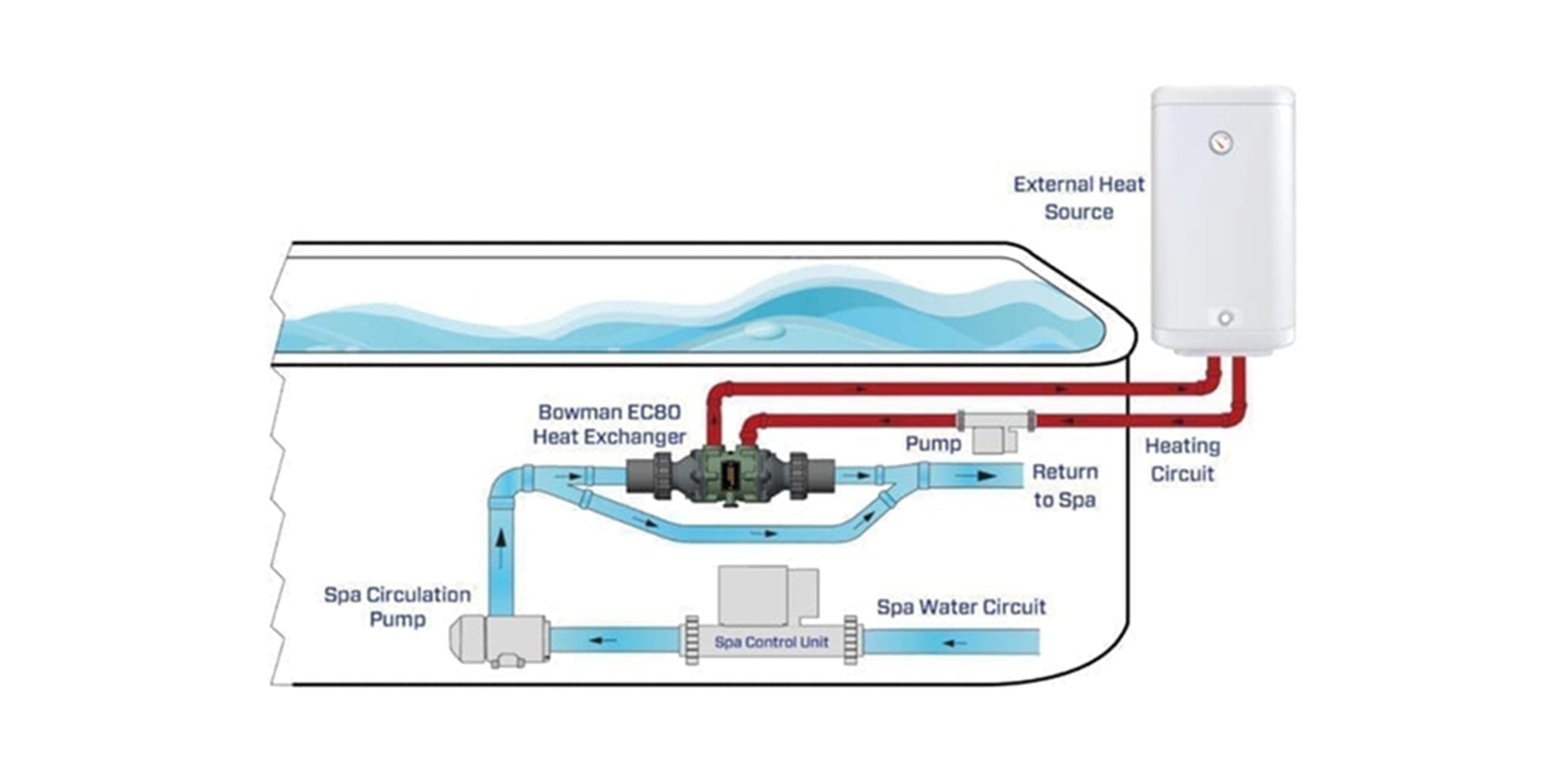

Bowman EC 80-5113-1T heat exchangers provide a new solution for heating spas and hot tubs in just a fraction of the time taken by traditional electric heaters.

Highly efficient heat transfer solutions for cooling marine, land-based and underground hydraulic systems.

Bowman inline plate heat exchangers are a compact, economical solution for high efficiency heat transfer.

Bespoke cooling solutions for a range of popular marine engines from major OEMs, including coolant heat exchangers, charge air coolers, plus combined heat exchangers and exhaust manifolds, suitable for cooling marine engines up to 1 MW.

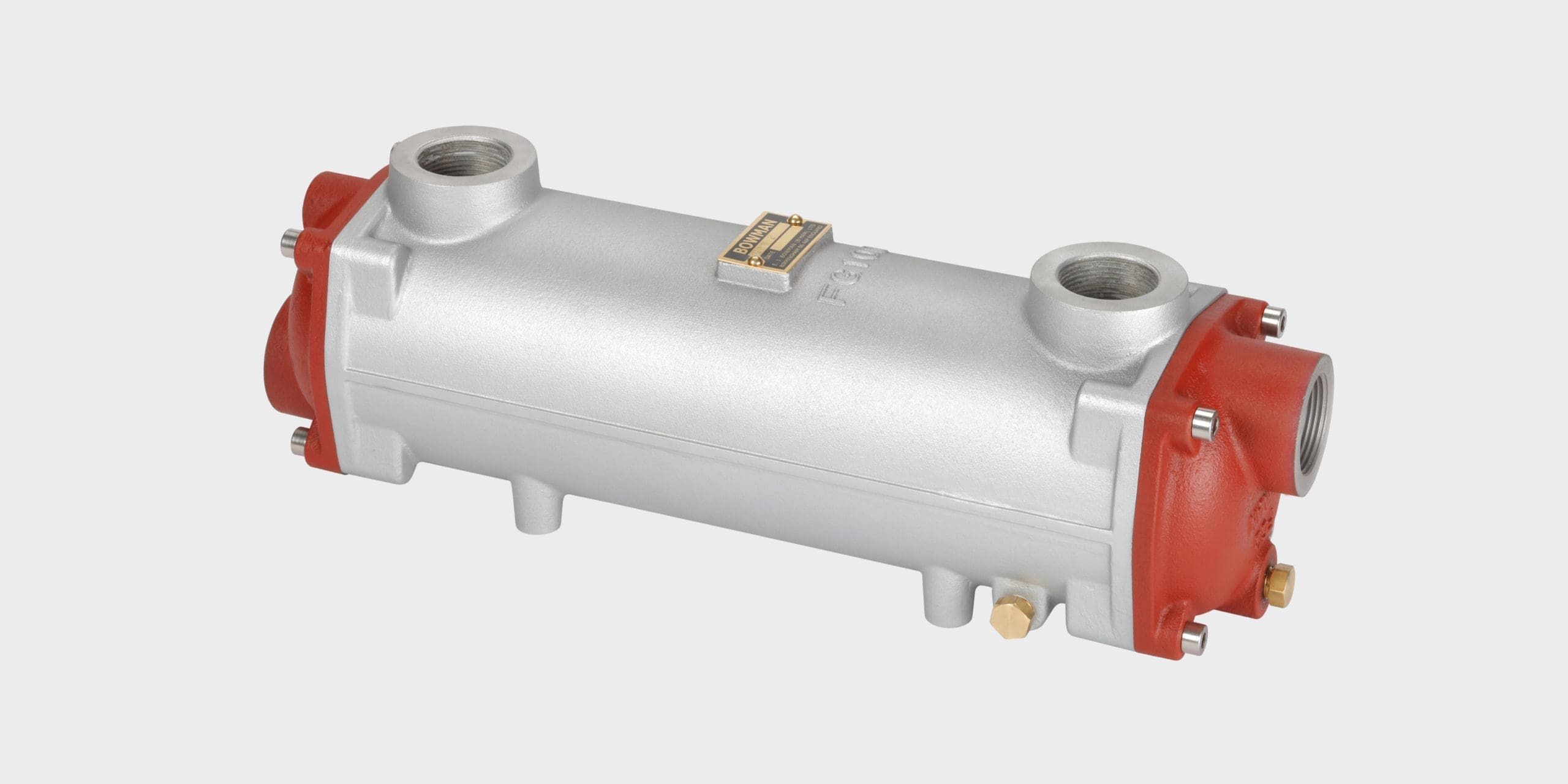

Bowman has a range of highly efficient oil coolers designed for marine and industrial engines and transmissions.

Efficient heat exchangers for cooling electric marine motors, hydrogen fuel cells, battery packs, chargers, AC-DC converters, DC-DC converters, inverters and associated equipment for electric and hybrid marine propulsion and charging systems.

Highly efficient heat transfer solutions for cooling a variety of applications where air and fluids need to be cooled by fluids.

Many applications require stainless steel shell and tube heat exchangers and Bowman provide a standard range of units that are suitable for cooling or heating a variety of fluids.

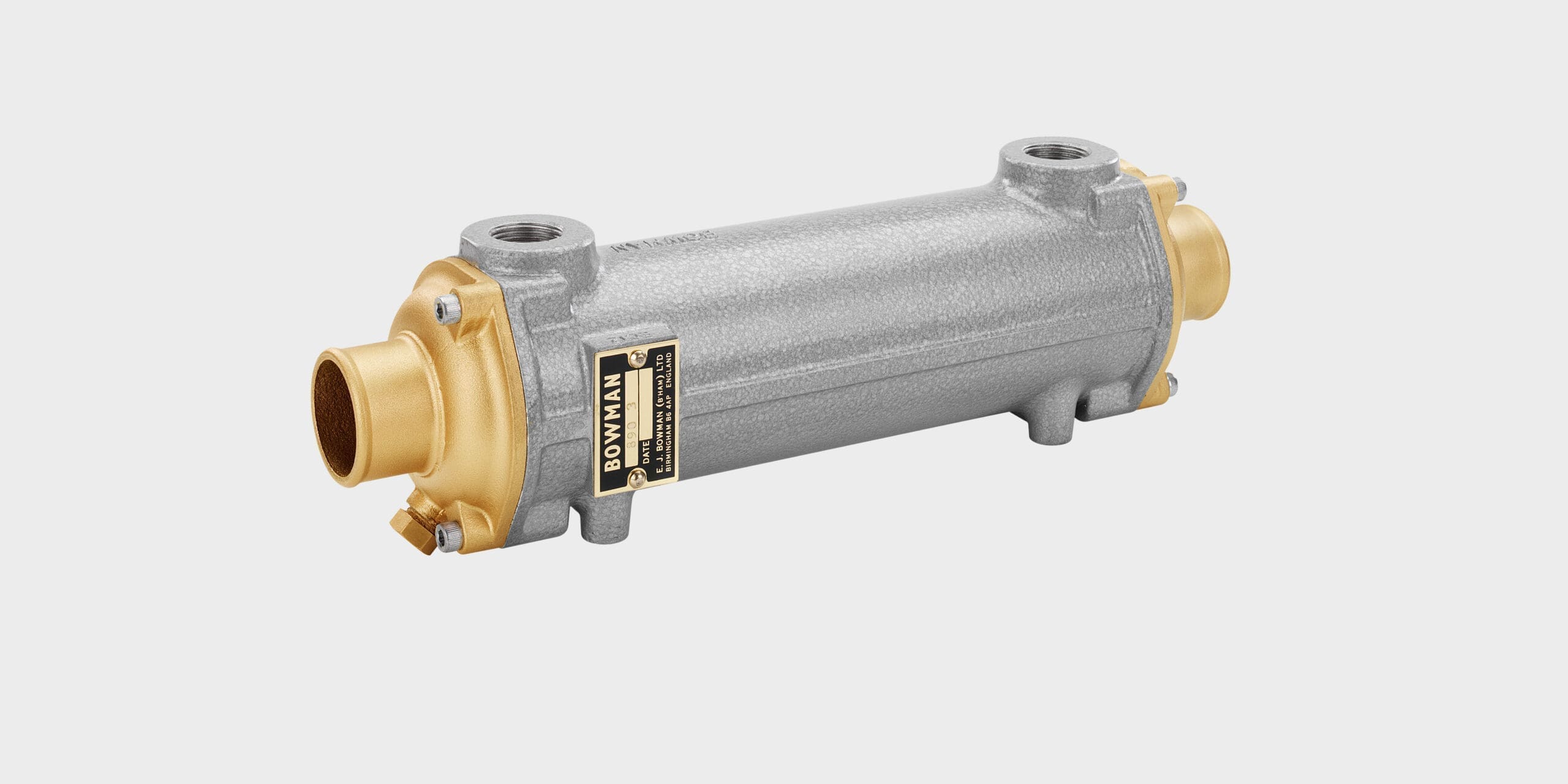

Bowman swimming pool heat exchangers are renowned for reliability and efficiency. Whether heating your pool with a traditional boiler or a renewable energy source, Bowman is the obvious choice.

Premium quality heat exchangers and oil coolers for precise temperature control of engines under test cell development conditions.

Recovering waste heat energy from engine powered generating sets for biogas, diesel and natural gas applications up to 1 MW.

Efficient cooling for stationary / land-based engines where air cooling is either unavailable or inappropriate.

The reliable solution for cooling Electric & Hybrid Marine Propulsion Systems.

A comprehensive oil cooling solution for industrial hydraulic control systems, plus high temperature and mining applications.

A complete solution for cooling complex on-board hydraulic equipment, including thruster and stabiliser systems.

The complete cooling solution for marine engine propulsion, including the latest electric and hybrid systems.

An energy efficient solution for heating hot tubs and swim spas faster, significantly reducing heat-up time for guest change-over periods.

Quality heat exchangers for efficient swimming pool heating, using boiler or renewable energy heat sources.

Biogas is becoming increasingly popular for fuelling generating sets. But why only generate power when you can recover heat too?

As a fuel, Biogas has much to recommend it.

It’s a renewable fuel produced by breaking down organic matter through the Anaerobic Digestion (AD) process. It reduces the amount of waste being sent to landfill and helps control the emission of Methane gas to the atmosphere (Methane is significantly more damaging to the environment than CO2). Biogas is also a suitable fuel for engine powered gen-sets and is carbon neutral.

So, it’s no surprise that Biogas is being widely used to generate energy as the world seeks to reduce its reliance on fossil fuels to reduce CO2-emissions.

If the story ended there, it would be a good one; but it would be only half the story, because generating sets creating electricity are generally inefficient. Only around 30% of all fuel energy that goes in to the generator gets converted to power. Nearly 50% is converted to heat and lost to atmosphere. Just by recovering the heat energy from the engine’s exhaust stream provides an additional energy source – at no additional cost in terms of fuel required!

So, why not recover this valuable energy source? One of the reasons may be the fuel itself. Biogas is an extremely aggressive fuel and requires careful control of the exhaust stream gas temperature. If the system is overcooled, it can create corrosion in fabricated carbon steel components, such as exhaust gas heat exchangers, leading to premature failure and the expense of replacing the unit.

The good news is that Bowman exhaust gas heat exchangers, being made entirely of 316L stainless steel, offer a long-life solution for recovering waste heat from Biogas, due to the superior material specification and quality of the manufacturing process.

Manufactured in the UK, every component is designed for longevity and durability, even when used with aggressing fuels such as Biogas and, consequently, Bowman exhaust gas heat exchangers offer much longer service life due to the quality of their construction.

For example, the cooling tubes undergo a two stage installation process ensuring they are permanently secured in the tube plate – first, they are roller expanded onto the tube plate and then automatically welded into position, creating a secure weld that is totally consistent across every tube in the heat exchanger. All end cover flanges and shell side flanges are PN6 to BS EN1092 for ease of installation.

Bowman exhaust gas heat exchangers are also easy to clean – an important consideration when using a fuel like Biogas, where residues can remain after combustion. They’re also available in a range of sizes and specifications to suit applications from 16 kW to 1 MW, whilst computer-aided selection software enables Bowman to recommend the right specification for each application.

Bowman exhaust gas heat exchangers are also easy to clean – an important consideration when using a fuel like Biogas, where residues can remain after combustion. They’re also available in a range of sizes and specifications to suit applications from 16 kW to 1 MW, whilst computer-aided selection software enables Bowman to recommend the right specification for each application.

The quality and performance of Bowman exhaust gas heat exchangers, has already led to them being selected by a number of AD plants, to replace the failed units originally supplied by others. Their compact design enables them to be easily retro-fitted to existing plant, making Bowman units a popular choice for Biogas replacement.

For further information, download the brochure or contact the technical sales team on +44 (0)121 359 5401 or email [email protected].

Biogas is becoming increasingly popular for fuelling generating sets. But why only generate power when you can recover heat too?

As a fuel, Biogas has much to recommend it.

It’s a renewable fuel produced by breaking down organic matter through the Anaerobic Digestion (AD) process. It reduces the amount of waste being sent to landfill and helps control the emission of Methane gas to the atmosphere (Methane is significantly more damaging to the environment than CO2). Biogas is also a suitable fuel for engine powered gen-sets and is carbon neutral.

So, it’s no surprise that Biogas is being widely used to generate energy as the world seeks to reduce its reliance on fossil fuels to reduce CO2-emissions.

If the story ended there, it would be a good one; but it would be only half the story, because generating sets creating electricity are generally inefficient. Only around 30% of all fuel energy that goes in to the generator gets converted to power. Nearly 50% is converted to heat and lost to atmosphere. Just by recovering the heat energy from the engine’s exhaust stream provides an additional energy source – at no additional cost in terms of fuel required!

So, why not recover this valuable energy source? One of the reasons may be the fuel itself. Biogas is an extremely aggressive fuel and requires careful control of the exhaust stream gas temperature. If the system is overcooled, it can create corrosion in fabricated carbon steel components, such as exhaust gas heat exchangers, leading to premature failure and the expense of replacing the unit.

The good news is that Bowman exhaust gas heat exchangers, being made entirely of 316L stainless steel, offer a long-life solution for recovering waste heat from Biogas, due to the superior material specification and quality of the manufacturing process.

Manufactured in the UK, every component is designed for longevity and durability, even when used with aggressing fuels such as Biogas and, consequently, Bowman exhaust gas heat exchangers offer much longer service life due to the quality of their construction.

For example, the cooling tubes undergo a two stage installation process ensuring they are permanently secured in the tube plate – first, they are roller expanded onto the tube plate and then automatically welded into position, creating a secure weld that is totally consistent across every tube in the heat exchanger. All end cover flanges and shell side flanges are PN6 to BS EN1092 for ease of installation.

Bowman exhaust gas heat exchangers are also easy to clean – an important consideration when using a fuel like Biogas, where residues can remain after combustion. They’re also available in a range of sizes and specifications to suit applications from 16 kW to 1 MW, whilst computer-aided selection software enables Bowman to recommend the right specification for each application.

Bowman exhaust gas heat exchangers are also easy to clean – an important consideration when using a fuel like Biogas, where residues can remain after combustion. They’re also available in a range of sizes and specifications to suit applications from 16 kW to 1 MW, whilst computer-aided selection software enables Bowman to recommend the right specification for each application.

The quality and performance of Bowman exhaust gas heat exchangers, has already led to them being selected by a number of AD plants, to replace the failed units originally supplied by others. Their compact design enables them to be easily retro-fitted to existing plant, making Bowman units a popular choice for Biogas replacement.

For further information, download the brochure or contact the technical sales team on +44 (0)121 359 5401 or email [email protected].

Bowman and Rinnai provide the perfect heating solution for an Australian roof top pool – where winter temperatures can be surprisingly cool!

Six Bowman heat exchangers have been installed at the recently opened Gold’s Gym, Amman, Jordan, to heat two half Olympic-sized swimming pools.

How Bowman heat exchangers are helping this internationally renowned golf destination reduce energy costs and CO₂ emissions.

Bowman heat exchangers are playing an important role in the success of a flagship hotel on the Black Sea coast in Georgia.

Bowman and Rinnai provide the perfect heating solution for an Australian roof top pool – where winter temperatures can be surprisingly cool!

Six Bowman heat exchangers have been installed at the recently opened Gold’s Gym, Amman, Jordan, to heat two half Olympic-sized swimming pools.

How Bowman heat exchangers are helping this internationally renowned golf destination reduce energy costs and CO₂ emissions.

Bowman heat exchangers are playing an important role in the success of a flagship hotel on the Black Sea coast in Georgia.