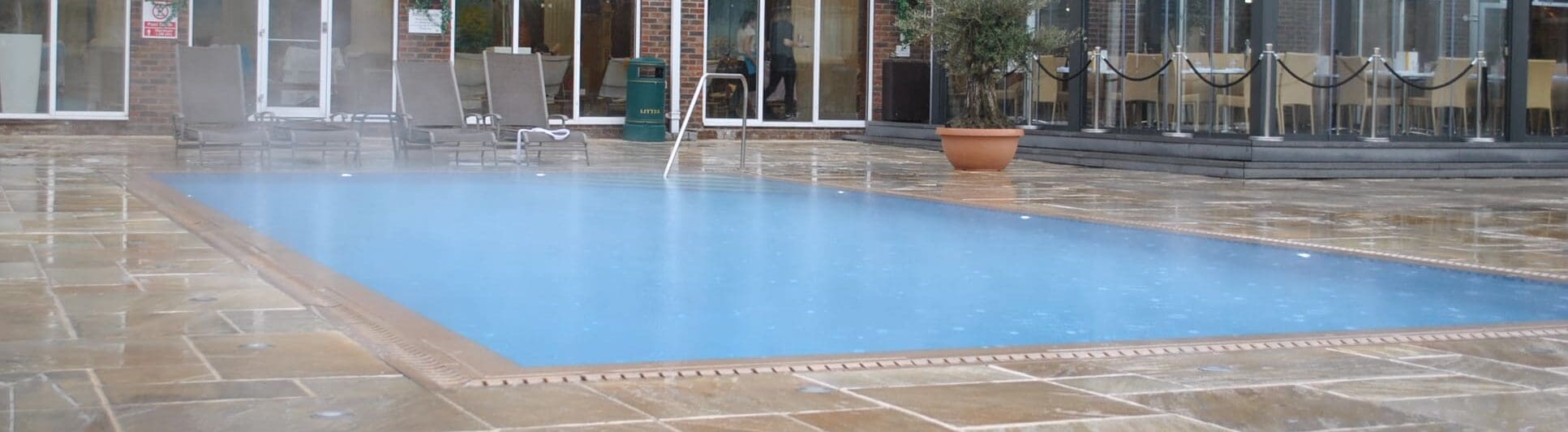

Rooftop swimming pool heating in Perth, WA

Bowman and Rinnai provide the perfect heating solution for an Australian roof top pool – where winter temperatures can be surprisingly cool!

Used to cool the hot, compressed air from the turbo before it reaches the engine, the intercoolers improve engine efficiency and reduce emissions for marine and land-based stationary engines.

Exhaust gas heat exchangers are designed to recover waste heat energy from the exhaust stream of reciprocating engine powered generating sets.

Bowman 'copper free' fuel coolers are compact, highly efficient heat exchangers suitable for fuel conditioning rigs in the automotive testing industry.

Engine coolant header tank heat exchangers for marine propulsion, gensets or stationary land-based engines.

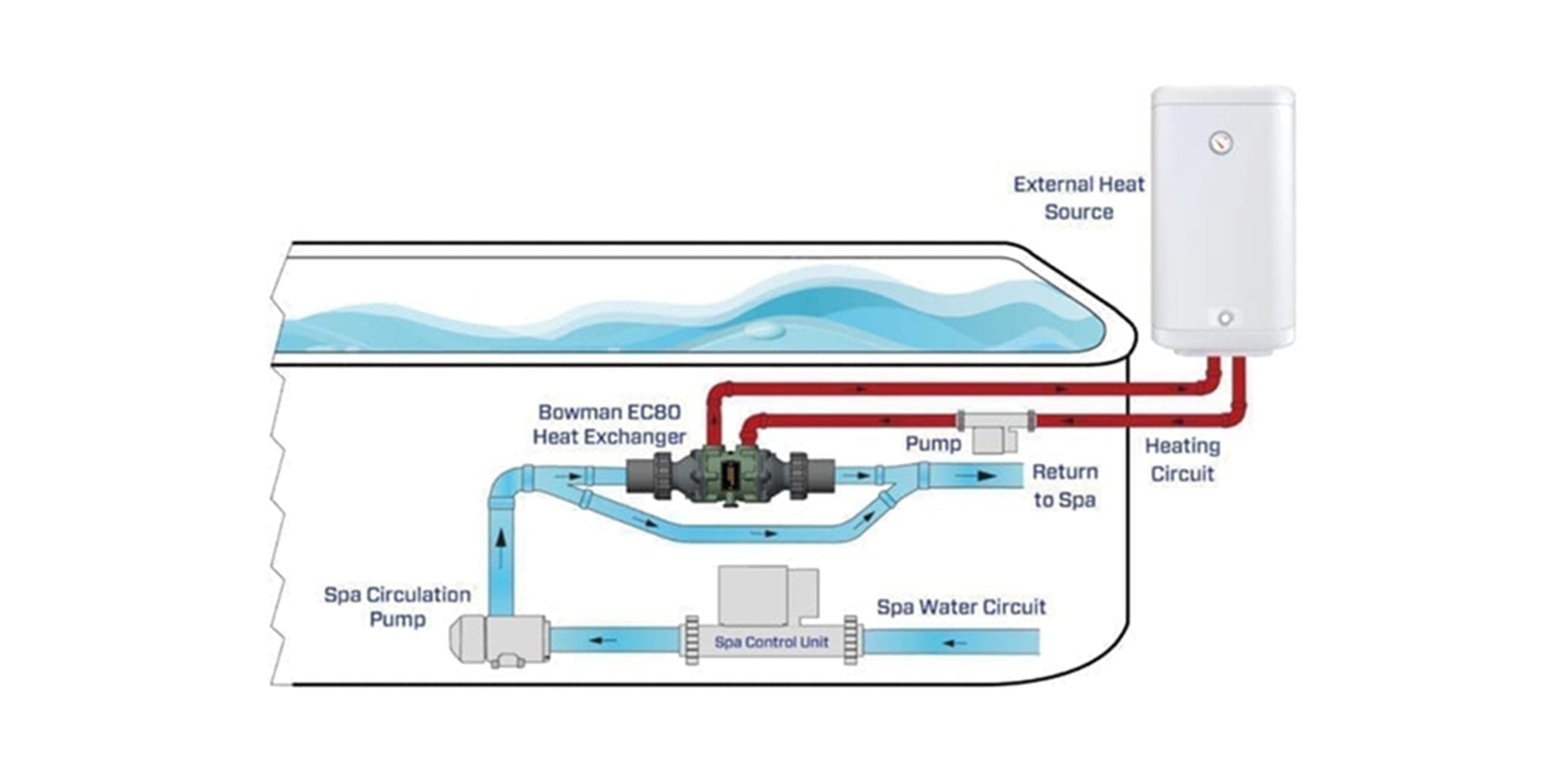

Bowman EC 80-5113-1T heat exchangers provide a new solution for heating spas and hot tubs in just a fraction of the time taken by traditional electric heaters.

Highly efficient heat transfer solutions for cooling marine, land-based and underground hydraulic systems.

Bowman inline plate heat exchangers are a compact, economical solution for high efficiency heat transfer.

Bespoke cooling solutions for a range of popular marine engines from major OEMs, including coolant heat exchangers, charge air coolers, plus combined heat exchangers and exhaust manifolds, suitable for cooling marine engines up to 1 MW.

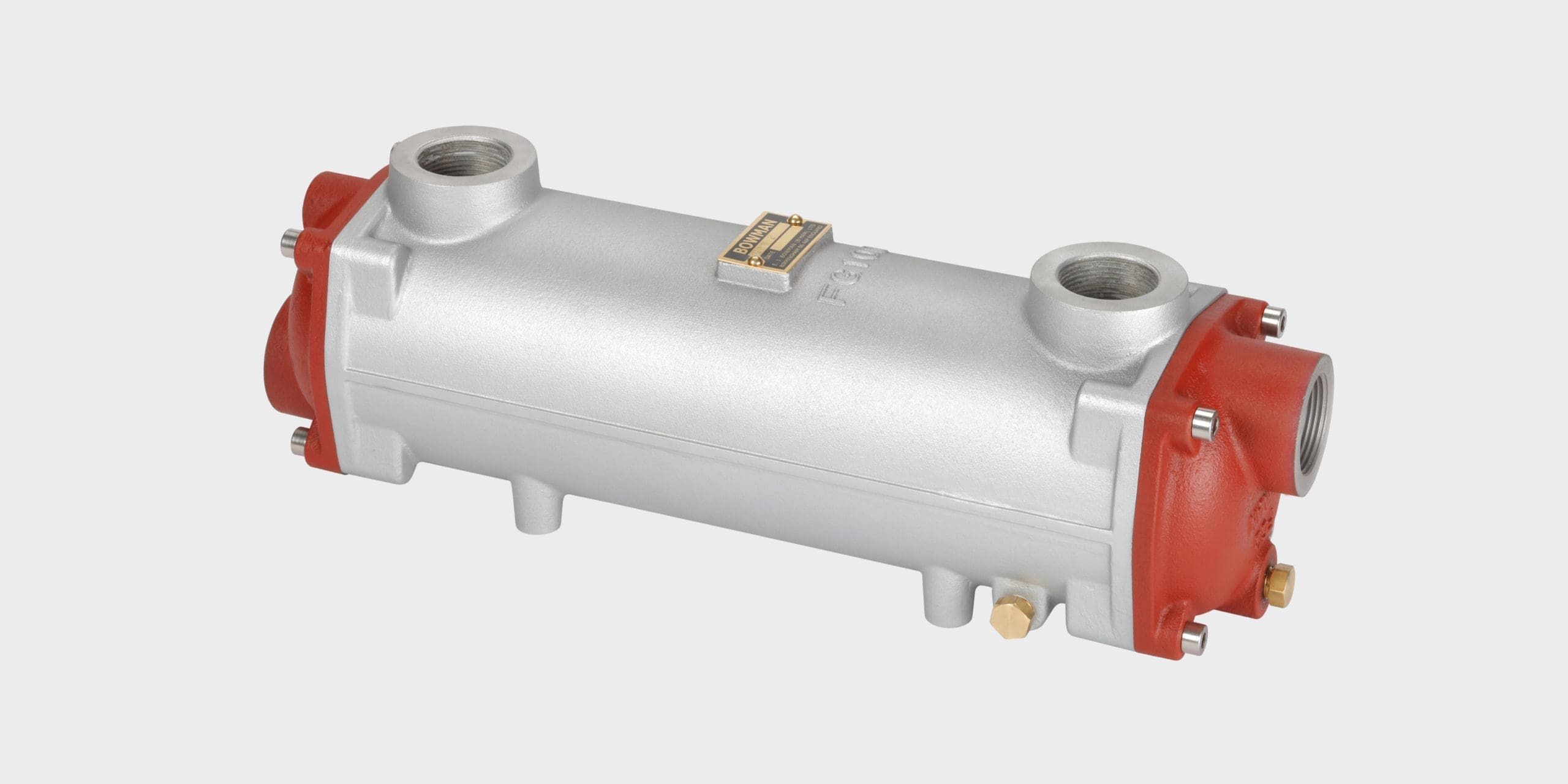

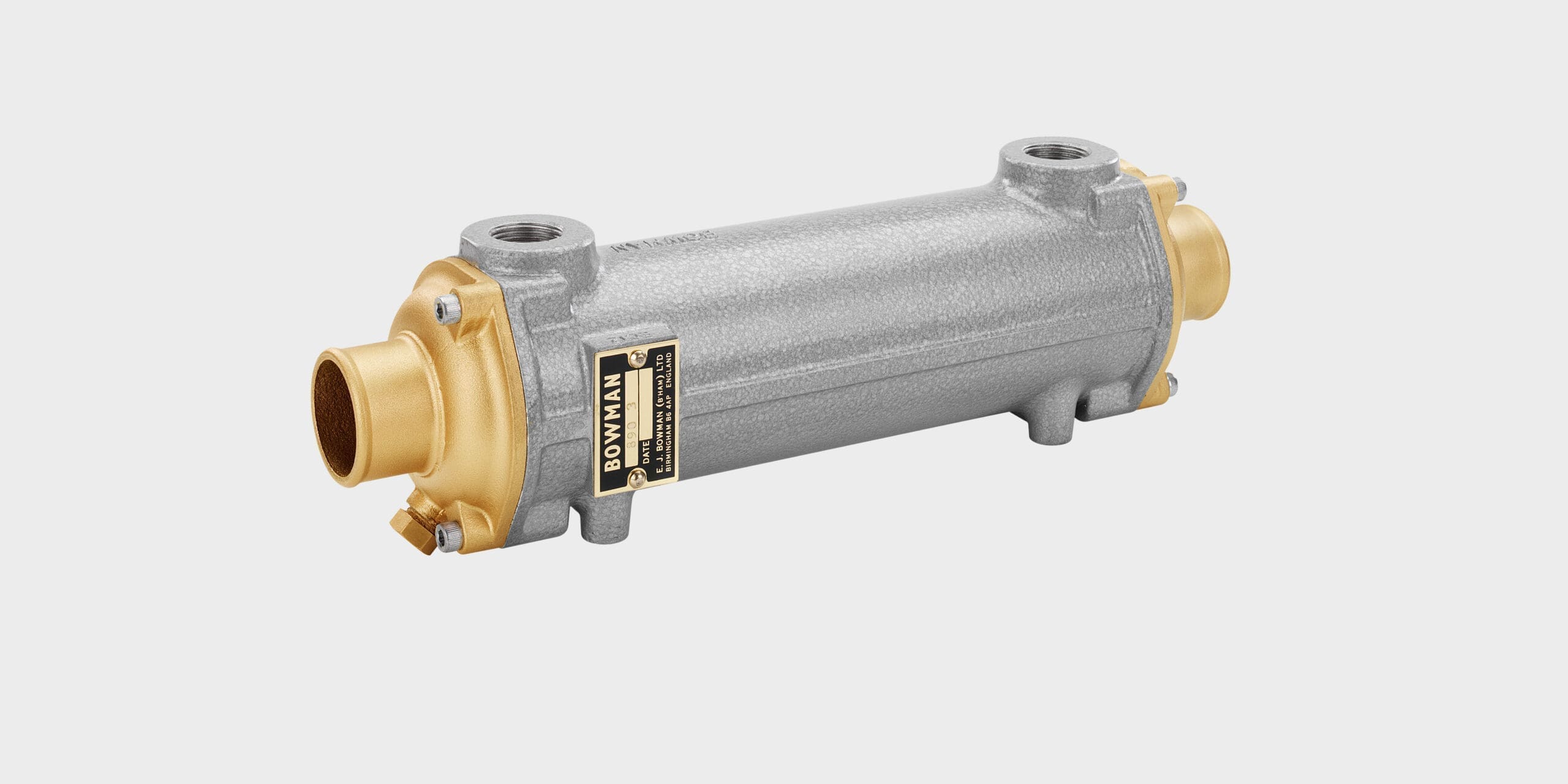

Bowman has a range of highly efficient oil coolers designed for marine and industrial engines and transmissions.

Efficient heat exchangers for cooling electric marine motors, hydrogen fuel cells, battery packs, chargers, AC-DC converters, DC-DC converters, inverters and associated equipment for electric and hybrid marine propulsion and charging systems.

Highly efficient heat transfer solutions for cooling a variety of applications where air and fluids need to be cooled by fluids.

Many applications require stainless steel shell and tube heat exchangers and Bowman provide a standard range of units that are suitable for cooling or heating a variety of fluids.

Bowman swimming pool heat exchangers are renowned for reliability and efficiency. Whether heating your pool with a traditional boiler or a renewable energy source, Bowman is the obvious choice.

Premium quality heat exchangers and oil coolers for precise temperature control of engines under test cell development conditions.

Recovering waste heat energy from engine powered generating sets for biogas, diesel and natural gas applications up to 1 MW.

Efficient cooling for stationary / land-based engines where air cooling is either unavailable or inappropriate.

The reliable solution for cooling Electric & Hybrid Marine Propulsion Systems.

A comprehensive oil cooling solution for industrial hydraulic control systems, plus high temperature and mining applications.

A complete solution for cooling complex on-board hydraulic equipment, including thruster and stabiliser systems.

The complete cooling solution for marine engine propulsion, including the latest electric and hybrid systems.

An energy efficient solution for heating hot tubs and swim spas faster, significantly reducing heat-up time for guest change-over periods.

Quality heat exchangers for efficient swimming pool heating, using boiler or renewable energy heat sources.

Why doesn’t my pool heat up faster

If your pool isn’t heating up to the required temperature, there are a few possible causes. Using this check list could help you locate the problem:

1: Do I have enough energy?

Whether heating your pool with a gas boiler, solar panels, a heat pump, or another energy source, it is important you have enough energy to do the job. There are some quite complex programs used to determine how much energy is required to heat a given volume of water.

Important considerations include, what is the ambient temperature; how many months of the year you plan to use it; is the pool located indoor or outdoor; is it an ‘in ground’ or ‘above ground’ installation? Other factors, such as humidity and altitude are also important.

It’s very common to find the installed heat source to be undersized for the pool size and operating conditions. If this is the case, your pool may be able to reach the desired temperature during the warmer months, but will fail to do so when the ambient temperature drops.

If the selection of the heat source was significantly lower than required, the pool may never reach a temperature that is comfortable to swim in.

However, if you know the heat source is providing adequate kWh to heat the pool, then the problem lies elsewhere!

2: Do I have the right heat exchanger?

A common misconception is the larger the heat exchanger, the faster it heats the pool! However, this isn’t necessarily the case. Heat exchangers transfer thermal energy to the pool water, so assuming you have enough energy, the next thing to check is whether your heat exchanger can transfer that energy.

There are many types of heat exchangers used to heat swimming pools and they differ dramatically in design, performance and heat transfer efficiency.

Some heat exchanger designs look large and impressive, but internally have only a very small heat transfer surface area – which provides the contact between the pool water and the heated water. If the unit doesn’t have enough surface area, no matter how much energy you put into the heat exchanger, you will not be able to transfer all of it to the pool.

Heat exchangers normally have a kW rating. This refers to the amount of thermal energy they can transfer, based on a specific duty cycle and this is sometimes why units are wrongly selected.

For example, a heat exchanger rated to transfer 50 kWh from a boiler producing hot water at 90 °C, flowing at 60 litres per minute, will not transfer the same energy, if the temperature and / or flow rate of the hot water is reduced.

Generally speaking, the lower the temperature and the flow rate (often applicable to renewable energy sources and condensing boilers), the larger the surface area required to transfer the heat to the pool. In such situations, heat exchanger design is critical and choosing the correct one can improve efficiency and heat-up times significantly – for more information see our article How do I heat my pool faster?

3: My heating system is adequate but my pool still fails to heat up!

Flow rates of both the hot and cold fluids are vital for the heat exchanger to transfer thermal energy to the pool. If the hot water flow rate is too low, the available energy will not be passed through the heat exchanger. However, the flow rate of the pool water is equally important.

People often think it is important to generate a large temperature differential between the pool water entering and leaving the heat exchanger. They are happy, if the pipework connected to the outlet of the heat exchanger is noticeably warmer than it is at the inlet.

In reality, this actually reducesthe efficiency of the heat transfer process! This is because the pool water flow is too low – the water remains in the heat exchanger for too long, so, a much smaller volume of water is being heated to a slightly higher temperature. It’s like trying to heat your pool by adding a kettle of boiling water – you would never do it because heat from the small volume of boiling water would soon be dissipated and lost in the larger volume of pool water.

However, with higher flow rates, the time taken to turn over the pool water will reduce and even a small increase in the temperature of the pool water through the heat exchanger (1.5 °C for example) will have a greater effect on the heating efficiency of the pool.

Using Bowman heat exchangers at their maximum recommended flow rates means you will have the best chance of transferring all the available energy from your heat source to the pool water.

4: And if you’ve done all that…..

Even if all the equipment is adequately sized, there may still be other parts of the system creating issues that will need to be checked.

For example, you may find that the pumps are worn. Or maybe there are leaks or blockages in the system which will impact the flow rates and heating performance.

All of these issues can be resolved to get your pool up to the required temperature and operating efficiently. If you have concerns about the efficiency of your heat exchanger, contact our technical sales team, who may be able to provide helpful advice. Below are some examples of customers who did and how we were able to help them;

In the UK – a 58 cu/m outdoor pool, plus a 44 cu/m indoor pool, both heated via a ground source heat pump system, just couldn’t get the pools up to temperature. The problem was traced to the poor heat transfer performance of the two stainless steel heat exchangers and swapping them for two Bowman EC160-5113-5S quickly resolved the problem. Read the story here.

In New Zealand – 2 units initially installed on a solar-heated pool were believed to be underperforming and were swapped for larger units. When the larger replacements still underperformed, close investigation revealed some installation errors – the heating circuit had no pressure and the pumps were set too low. By re-pressurising the system and increasing the flow, the original heat exchangers worked perfectly and the correct temperature was achieved.

In Sweden – a customer heating a 4 m x 8 m x 1.35 m pool was experiencing difficulty getting the pool to the desired temperature of 31 °C. The heating system included a boiler supplying hot water at 55 °C to a Bowman EC100-5113-2T heat exchanger, which is rated at 50 kW, using 82 °C boiler water. A detailed system check revealed the boiler was underperforming – the water being heated to just 40 °C! Resetting the boiler cured the problem, the heat exchanger achieving the required pool temperature, even with lower than recommended boiler water temperature!

5: In summary…..

DO – ensure you have the correct amount of heat energy required to heat the pool.

DO – make sure the hot and cold water flow rates are optimised for the system.

DO – check the heat exchanger is the correct size for the pool water capacity and heat energy source.

DON’T – panic! If you’re unsure of any of the issues relating to your pool, speak to a pool specialist or knowledgeable plumber. If you need more information about heat exchangers, speak to Bowman!

Why doesn’t my pool heat up faster

If your pool isn’t heating up to the required temperature, there are a few possible causes. Using this check list could help you locate the problem:

1: Do I have enough energy?

Whether heating your pool with a gas boiler, solar panels, a heat pump, or another energy source, it is important you have enough energy to do the job. There are some quite complex programs used to determine how much energy is required to heat a given volume of water.

Important considerations include, what is the ambient temperature; how many months of the year you plan to use it; is the pool located indoor or outdoor; is it an ‘in ground’ or ‘above ground’ installation? Other factors, such as humidity and altitude are also important.

It’s very common to find the installed heat source to be undersized for the pool size and operating conditions. If this is the case, your pool may be able to reach the desired temperature during the warmer months, but will fail to do so when the ambient temperature drops.

If the selection of the heat source was significantly lower than required, the pool may never reach a temperature that is comfortable to swim in.

However, if you know the heat source is providing adequate kWh to heat the pool, then the problem lies elsewhere!

2: Do I have the right heat exchanger?

A common misconception is the larger the heat exchanger, the faster it heats the pool! However, this isn’t necessarily the case. Heat exchangers transfer thermal energy to the pool water, so assuming you have enough energy, the next thing to check is whether your heat exchanger can transfer that energy.

There are many types of heat exchangers used to heat swimming pools and they differ dramatically in design, performance and heat transfer efficiency.

Some heat exchanger designs look large and impressive, but internally have only a very small heat transfer surface area – which provides the contact between the pool water and the heated water. If the unit doesn’t have enough surface area, no matter how much energy you put into the heat exchanger, you will not be able to transfer all of it to the pool.

Heat exchangers normally have a kW rating. This refers to the amount of thermal energy they can transfer, based on a specific duty cycle and this is sometimes why units are wrongly selected.

For example, a heat exchanger rated to transfer 50 kWh from a boiler producing hot water at 90 °C, flowing at 60 litres per minute, will not transfer the same energy, if the temperature and / or flow rate of the hot water is reduced.

Generally speaking, the lower the temperature and the flow rate (often applicable to renewable energy sources and condensing boilers), the larger the surface area required to transfer the heat to the pool. In such situations, heat exchanger design is critical and choosing the correct one can improve efficiency and heat-up times significantly – for more information see our article How do I heat my pool faster?

3: My heating system is adequate but my pool still fails to heat up!

Flow rates of both the hot and cold fluids are vital for the heat exchanger to transfer thermal energy to the pool. If the hot water flow rate is too low, the available energy will not be passed through the heat exchanger. However, the flow rate of the pool water is equally important.

People often think it is important to generate a large temperature differential between the pool water entering and leaving the heat exchanger. They are happy, if the pipework connected to the outlet of the heat exchanger is noticeably warmer than it is at the inlet.

In reality, this actually reducesthe efficiency of the heat transfer process! This is because the pool water flow is too low – the water remains in the heat exchanger for too long, so, a much smaller volume of water is being heated to a slightly higher temperature. It’s like trying to heat your pool by adding a kettle of boiling water – you would never do it because heat from the small volume of boiling water would soon be dissipated and lost in the larger volume of pool water.

However, with higher flow rates, the time taken to turn over the pool water will reduce and even a small increase in the temperature of the pool water through the heat exchanger (1.5 °C for example) will have a greater effect on the heating efficiency of the pool.

Using Bowman heat exchangers at their maximum recommended flow rates means you will have the best chance of transferring all the available energy from your heat source to the pool water.

4: And if you’ve done all that…..

Even if all the equipment is adequately sized, there may still be other parts of the system creating issues that will need to be checked.

For example, you may find that the pumps are worn. Or maybe there are leaks or blockages in the system which will impact the flow rates and heating performance.

All of these issues can be resolved to get your pool up to the required temperature and operating efficiently. If you have concerns about the efficiency of your heat exchanger, contact our technical sales team, who may be able to provide helpful advice. Below are some examples of customers who did and how we were able to help them;

In the UK – a 58 cu/m outdoor pool, plus a 44 cu/m indoor pool, both heated via a ground source heat pump system, just couldn’t get the pools up to temperature. The problem was traced to the poor heat transfer performance of the two stainless steel heat exchangers and swapping them for two Bowman EC160-5113-5S quickly resolved the problem. Read the story here.

In New Zealand – 2 units initially installed on a solar-heated pool were believed to be underperforming and were swapped for larger units. When the larger replacements still underperformed, close investigation revealed some installation errors – the heating circuit had no pressure and the pumps were set too low. By re-pressurising the system and increasing the flow, the original heat exchangers worked perfectly and the correct temperature was achieved.

In Sweden – a customer heating a 4 m x 8 m x 1.35 m pool was experiencing difficulty getting the pool to the desired temperature of 31 °C. The heating system included a boiler supplying hot water at 55 °C to a Bowman EC100-5113-2T heat exchanger, which is rated at 50 kW, using 82 °C boiler water. A detailed system check revealed the boiler was underperforming – the water being heated to just 40 °C! Resetting the boiler cured the problem, the heat exchanger achieving the required pool temperature, even with lower than recommended boiler water temperature!

5: In summary…..

DO – ensure you have the correct amount of heat energy required to heat the pool.

DO – make sure the hot and cold water flow rates are optimised for the system.

DO – check the heat exchanger is the correct size for the pool water capacity and heat energy source.

DON’T – panic! If you’re unsure of any of the issues relating to your pool, speak to a pool specialist or knowledgeable plumber. If you need more information about heat exchangers, speak to Bowman!

Bowman and Rinnai provide the perfect heating solution for an Australian roof top pool – where winter temperatures can be surprisingly cool!

Six Bowman heat exchangers have been installed at the recently opened Gold’s Gym, Amman, Jordan, to heat two half Olympic-sized swimming pools.

How Bowman heat exchangers are helping this internationally renowned golf destination reduce energy costs and CO₂ emissions.

Bowman heat exchangers are playing an important role in the success of a flagship hotel on the Black Sea coast in Georgia.

Bowman and Rinnai provide the perfect heating solution for an Australian roof top pool – where winter temperatures can be surprisingly cool!

Six Bowman heat exchangers have been installed at the recently opened Gold’s Gym, Amman, Jordan, to heat two half Olympic-sized swimming pools.

How Bowman heat exchangers are helping this internationally renowned golf destination reduce energy costs and CO₂ emissions.

Bowman heat exchangers are playing an important role in the success of a flagship hotel on the Black Sea coast in Georgia.