Rooftop swimming pool heating in Perth, WA

Bowman and Rinnai provide the perfect heating solution for an Australian roof top pool – where winter temperatures can be surprisingly cool!

Used to cool the hot, compressed air from the turbo before it reaches the engine, the intercoolers improve engine efficiency and reduce emissions for marine and land-based stationary engines.

Exhaust gas heat exchangers are designed to recover waste heat energy from the exhaust stream of reciprocating engine powered generating sets.

Bowman 'copper free' fuel coolers are compact, highly efficient heat exchangers suitable for fuel conditioning rigs in the automotive testing industry.

Engine coolant header tank heat exchangers for marine propulsion, gensets or stationary land-based engines.

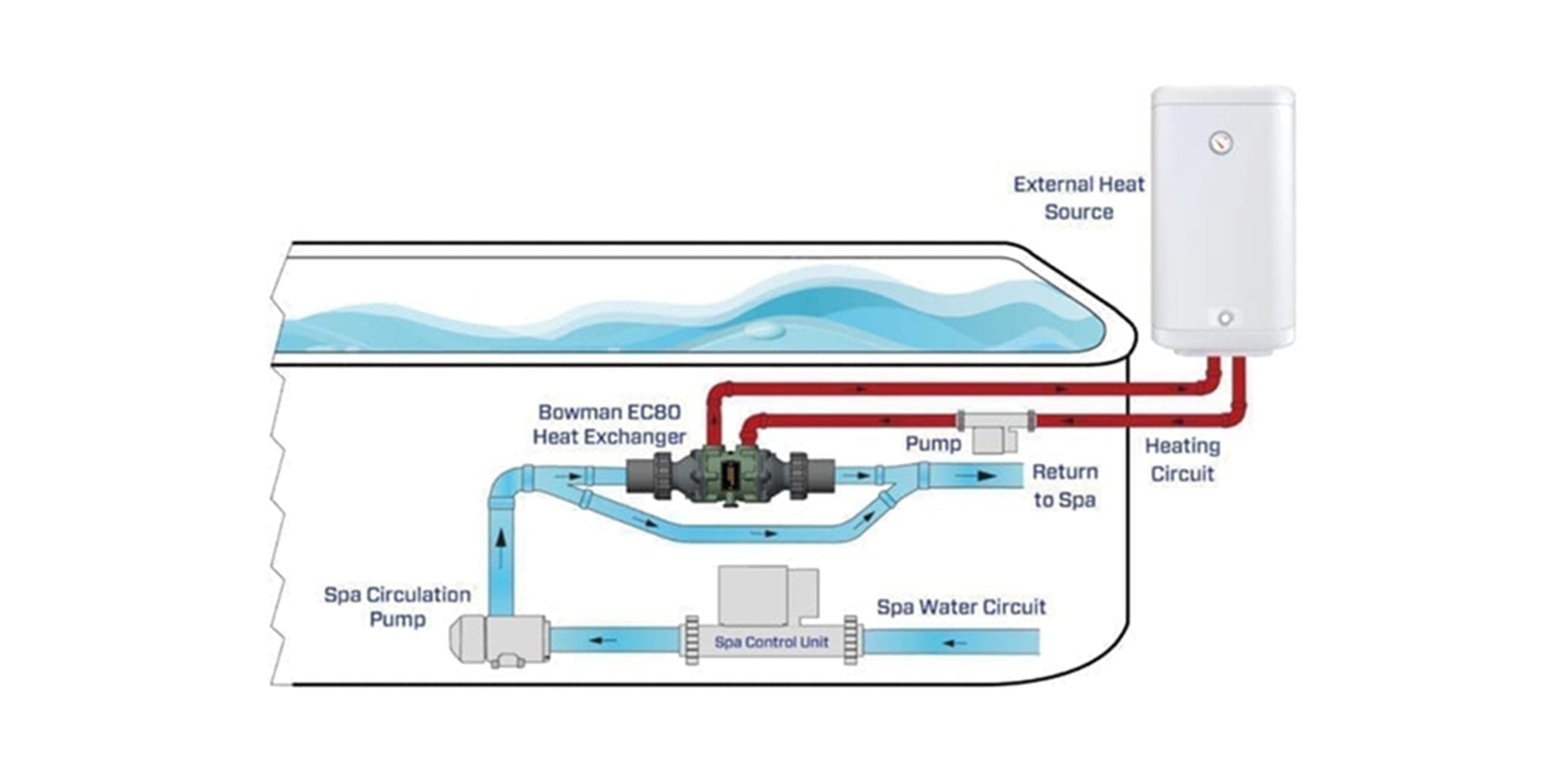

Bowman EC 80-5113-1T heat exchangers provide a new solution for heating spas and hot tubs in just a fraction of the time taken by traditional electric heaters.

Highly efficient heat transfer solutions for cooling marine, land-based and underground hydraulic systems.

Bowman inline plate heat exchangers are a compact, economical solution for high efficiency heat transfer.

Bespoke cooling solutions for a range of popular marine engines from major OEMs, including coolant heat exchangers, charge air coolers, plus combined heat exchangers and exhaust manifolds, suitable for cooling marine engines up to 1 MW.

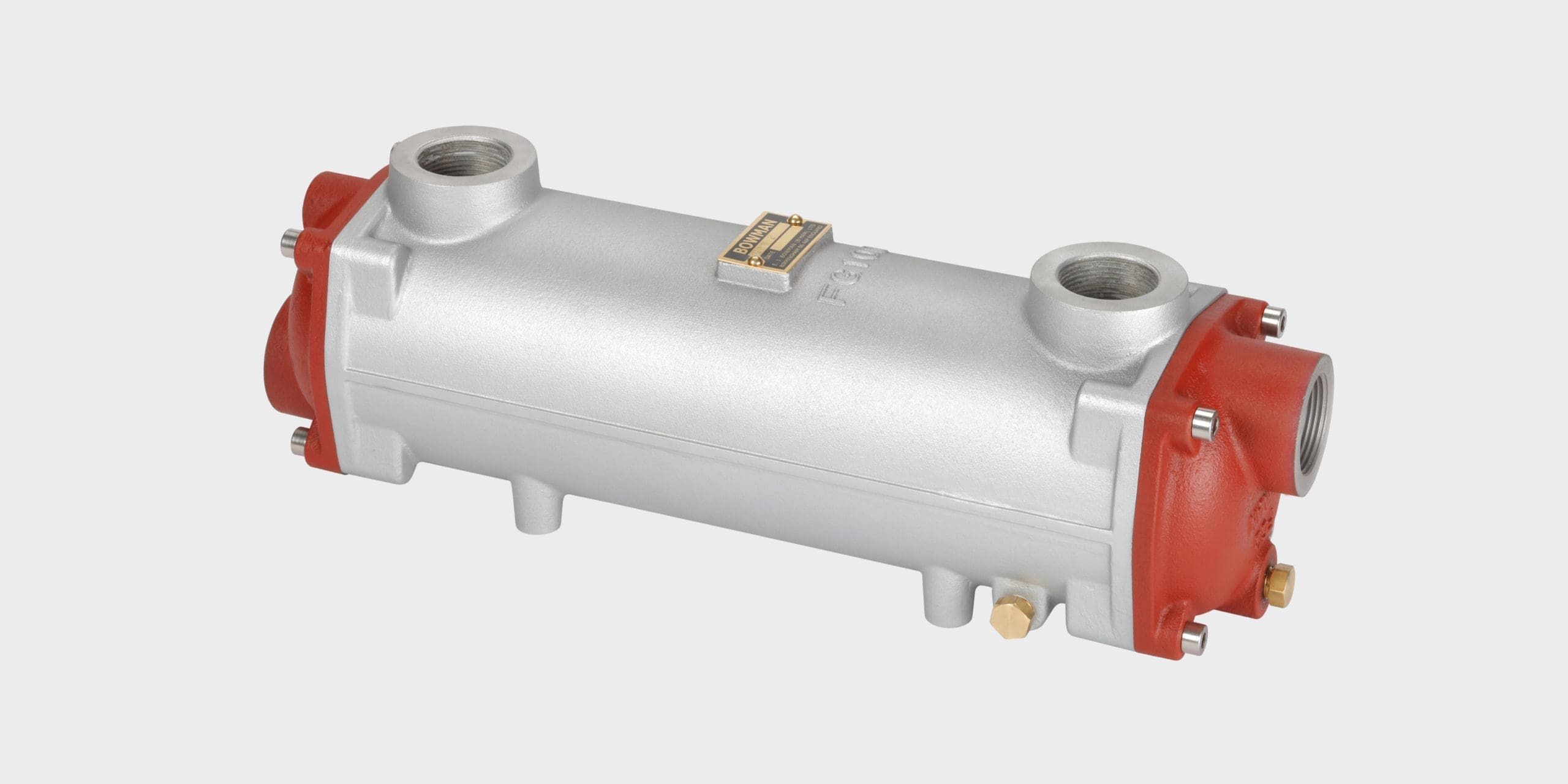

Bowman has a range of highly efficient oil coolers designed for marine and industrial engines and transmissions.

Efficient heat exchangers for cooling electric marine motors, hydrogen fuel cells, battery packs, chargers, AC-DC converters, DC-DC converters, inverters and associated equipment for electric and hybrid marine propulsion and charging systems.

Highly efficient heat transfer solutions for cooling a variety of applications where air and fluids need to be cooled by fluids.

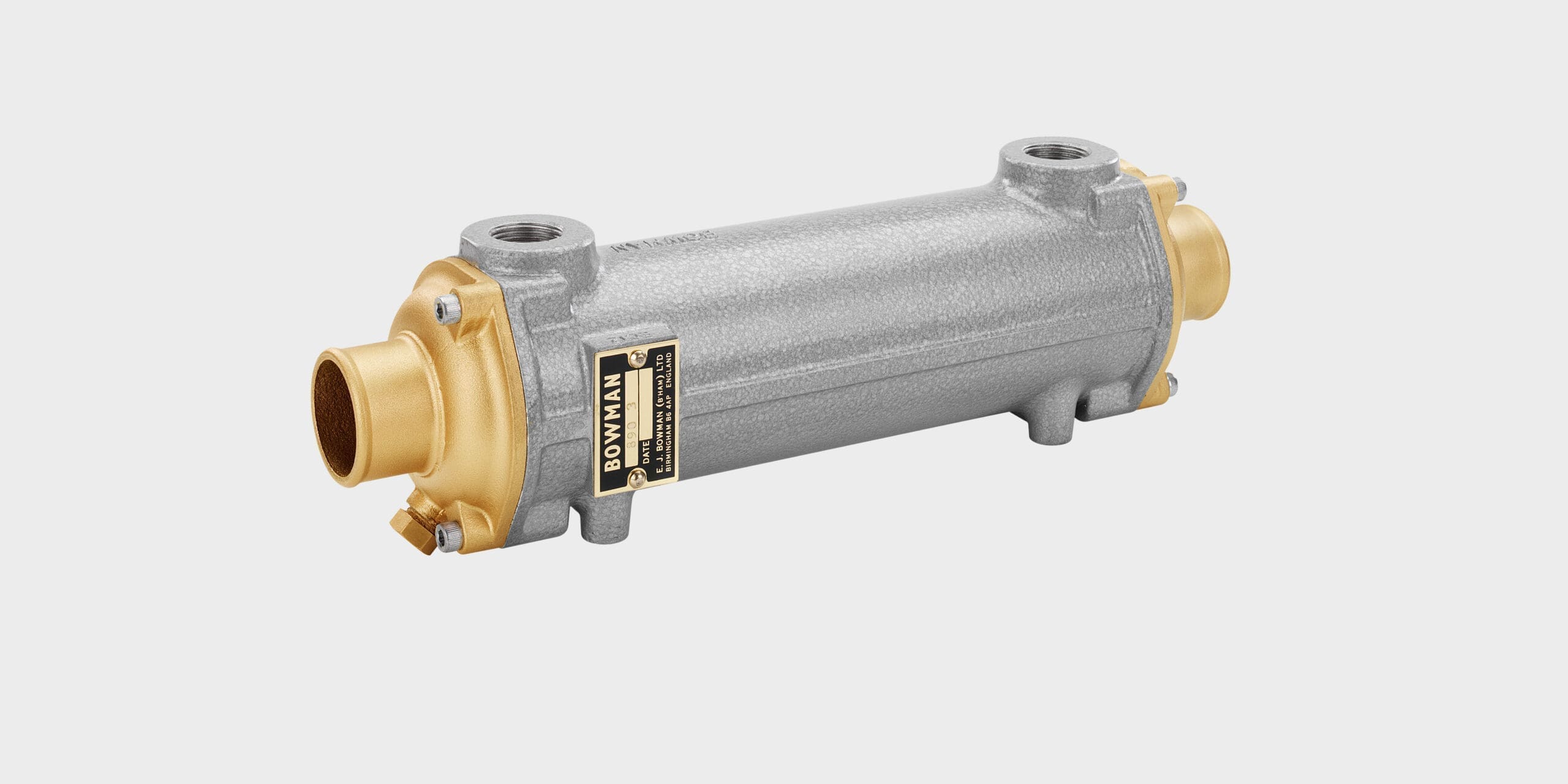

Many applications require stainless steel shell and tube heat exchangers and Bowman provide a standard range of units that are suitable for cooling or heating a variety of fluids.

Bowman swimming pool heat exchangers are renowned for reliability and efficiency. Whether heating your pool with a traditional boiler or a renewable energy source, Bowman is the obvious choice.

Premium quality heat exchangers and oil coolers for precise temperature control of engines under test cell development conditions.

Recovering waste heat energy from engine powered generating sets for biogas, diesel and natural gas applications up to 1 MW.

Efficient cooling for stationary / land-based engines where air cooling is either unavailable or inappropriate.

The reliable solution for cooling Electric & Hybrid Marine Propulsion Systems.

A comprehensive oil cooling solution for industrial hydraulic control systems, plus high temperature and mining applications.

A complete solution for cooling complex on-board hydraulic equipment, including thruster and stabiliser systems.

The complete cooling solution for marine engine propulsion, including the latest electric and hybrid systems.

An energy efficient solution for heating hot tubs and swim spas faster, significantly reducing heat-up time for guest change-over periods.

Quality heat exchangers for efficient swimming pool heating, using boiler or renewable energy heat sources.

The range of facilities at UK holiday parks has improved dramatically, driven by the higher expectations of holidaymakers and the professional park owners who have risen to the challenge of satisfying those demands.

One such organisation is Forest Holidays, a ‘leading brand’ in high-quality, low density forest lodge holidays. Currently operating from 10 locations in England and Scotland, Forest Holidays have approaching 600 lodges and in keeping with customer expectations, most lodges have their own exclusive hot tub.

The attraction of hot tubs

The attraction of hot tubs

Hot tubs have proved to be a desirable attraction and demand is always high, so much so that all of the company’s future developments – and they’re planning for substantial growth over the next 10 years – will feature a guest hot tub at each lodge.

Whilst an undoubted benefit in terms of guest appeal, hot tubs can pose a problem for many commercial operators.

One major issue comes at guest changeover times. Staff often have just a few hours to service and prepare the tubs prior to new guests arriving. As many tubs are heated electrically, often with low powered heaters, they can take several hours to achieve temperature, so may not be ready for new arrivals.

High energy costs

The other problem is energy costs. Many hot tubs are heated using the most expensive energy source available – mains electricity. Consequently, energy costs can be in excess of £500 per tub/per year – a significant figure for holiday parks operating literally hundreds of hot tubs!

A new direction for hot tub heating

Forest Holidays identified the need to switch to a more sustainable heating approach for their hot tubs, to reduce energy costs and address the problem of heat-up times.

They researched a wide range of alternative heating systems, including biomass and heat pumps, before selecting an LPG/air source heat pump hybrid boiler system – complete with Bowman EC80 heat exchangers – as the most appropriate solution for their needs.

Results that speak for themselves

Forest Holidays has now embarked on a programme to convert all the hot tubs at its forest lodges to the new heating system. Early results, from independent tests carried out with LPG fired boilers linked to Bowman heat exchangers, have achieved hot tub heat-up times of just 1 hour, using pre-heated (25 ⁰C) water for the initial fill. Even using ambient temperature water, the hot tubs can be heated to full operating temperature in 2-3 hours.

If you go down to the woods today – you’ll find a hot tub heating revolution!

The range of facilities at UK holiday parks has improved dramatically, driven by the higher expectations of holidaymakers and the professional park owners who have risen to the challenge of satisfying those demands.

One such organisation is Forest Holidays, a ‘leading brand’ in high-quality, low density forest lodge holidays. Currently operating from 10 locations in England and Scotland, Forest Holidays have approaching 600 lodges and in keeping with customer expectations, most lodges have their own exclusive hot tub.

The attraction of hot tubs

The attraction of hot tubs

Hot tubs have proved to be a desirable attraction and demand is always high, so much so that all of the company’s future developments – and they’re planning for substantial growth over the next 10 years – will feature a guest hot tub at each lodge.

Whilst an undoubted benefit in terms of guest appeal, hot tubs can pose a problem for many commercial operators.

One major issue comes at guest changeover times. Staff often have just a few hours to service and prepare the tubs prior to new guests arriving. As many tubs are heated electrically, often with low powered heaters, they can take several hours to achieve temperature, so may not be ready for new arrivals.

High energy costs

The other problem is energy costs. Many hot tubs are heated using the most expensive energy source available – mains electricity. Consequently, energy costs can be in excess of £500 per tub/per year – a significant figure for holiday parks operating literally hundreds of hot tubs!

A new direction for hot tub heating

Forest Holidays identified the need to switch to a more sustainable heating approach for their hot tubs, to reduce energy costs and address the problem of heat-up times.

They researched a wide range of alternative heating systems, including biomass and heat pumps, before selecting an LPG/air source heat pump hybrid boiler system – complete with Bowman EC80 heat exchangers – as the most appropriate solution for their needs.

Results that speak for themselves

Forest Holidays has now embarked on a programme to convert all the hot tubs at its forest lodges to the new heating system. Early results, from independent tests carried out with LPG fired boilers linked to Bowman heat exchangers, have achieved hot tub heat-up times of just 1 hour, using pre-heated (25 ⁰C) water for the initial fill. Even using ambient temperature water, the hot tubs can be heated to full operating temperature in 2-3 hours.

More News from EJ Bowman

Bowman and Rinnai provide the perfect heating solution for an Australian roof top pool – where winter temperatures can be surprisingly cool!

Six Bowman heat exchangers have been installed at the recently opened Gold’s Gym, Amman, Jordan, to heat two half Olympic-sized swimming pools.

How Bowman heat exchangers are helping this internationally renowned golf destination reduce energy costs and CO₂ emissions.

Bowman heat exchangers are playing an important role in the success of a flagship hotel on the Black Sea coast in Georgia.

Bowman and Rinnai provide the perfect heating solution for an Australian roof top pool – where winter temperatures can be surprisingly cool!

Six Bowman heat exchangers have been installed at the recently opened Gold’s Gym, Amman, Jordan, to heat two half Olympic-sized swimming pools.

How Bowman heat exchangers are helping this internationally renowned golf destination reduce energy costs and CO₂ emissions.

Bowman heat exchangers are playing an important role in the success of a flagship hotel on the Black Sea coast in Georgia.