Charge Air Coolers

Used to cool the hot, compressed air from the turbo before it reaches the engine, the intercoolers improve engine efficiency and reduce emissions for marine and land-based stationary engines.

Used to cool the hot, compressed air from the turbo before it reaches the engine, the intercoolers improve engine efficiency and reduce emissions for marine and land-based stationary engines.

Exhaust gas heat exchangers are designed to recover waste heat energy from the exhaust stream of reciprocating engine powered generating sets.

Bowman 'copper free' fuel coolers are compact, highly efficient heat exchangers suitable for fuel conditioning rigs in the automotive testing industry.

Engine coolant header tank heat exchangers for marine propulsion, gensets or stationary land-based engines.

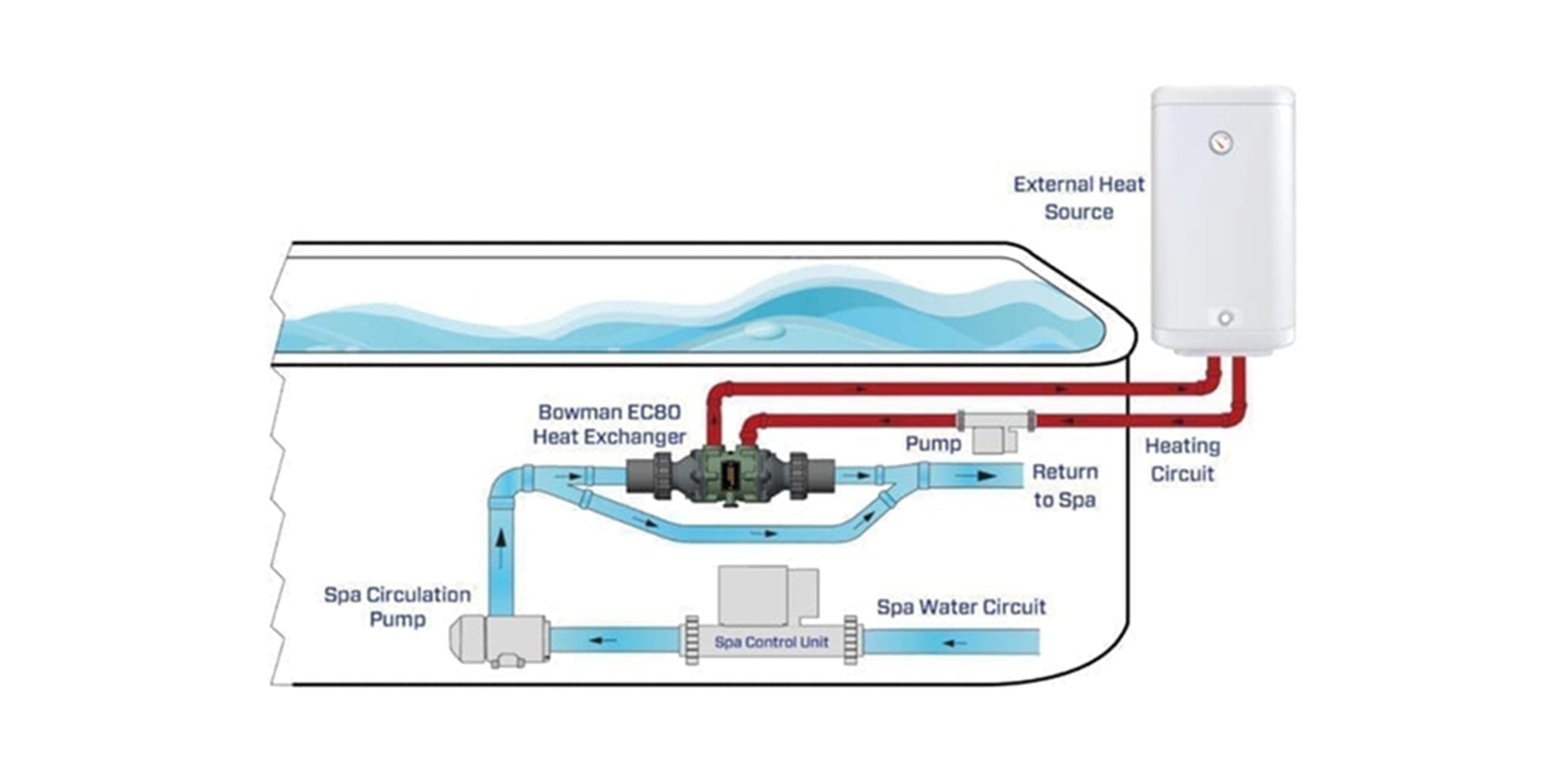

Bowman EC 80-5113-1T heat exchangers provide a new solution for heating spas and hot tubs in just a fraction of the time taken by traditional electric heaters.

Highly efficient heat transfer solutions for cooling marine, land-based and underground hydraulic systems.

Bowman inline plate heat exchangers are a compact, economical solution for high efficiency heat transfer.

Bespoke cooling solutions for a range of popular marine engines from major OEMs, including coolant heat exchangers, charge air coolers, plus combined heat exchangers and exhaust manifolds, suitable for cooling marine engines up to 1 MW.

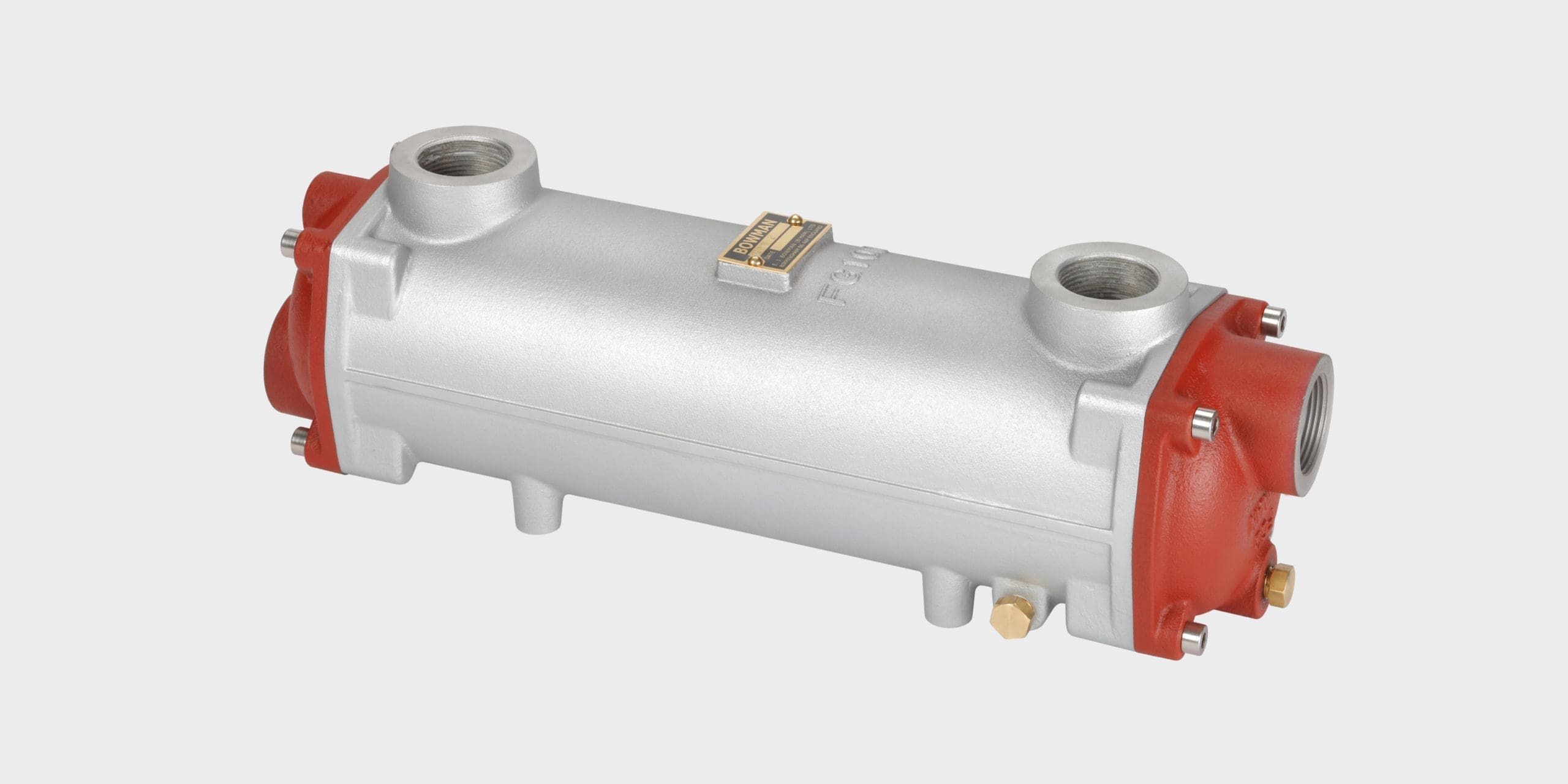

Bowman has a range of highly efficient oil coolers designed for marine and industrial engines and transmissions.

Efficient heat exchangers for cooling electric marine motors, hydrogen fuel cells, battery packs, chargers, AC-DC converters, DC-DC converters, inverters and associated equipment for electric and hybrid marine propulsion and charging systems.

Highly efficient heat transfer solutions for cooling a variety of applications where air and fluids need to be cooled by fluids.

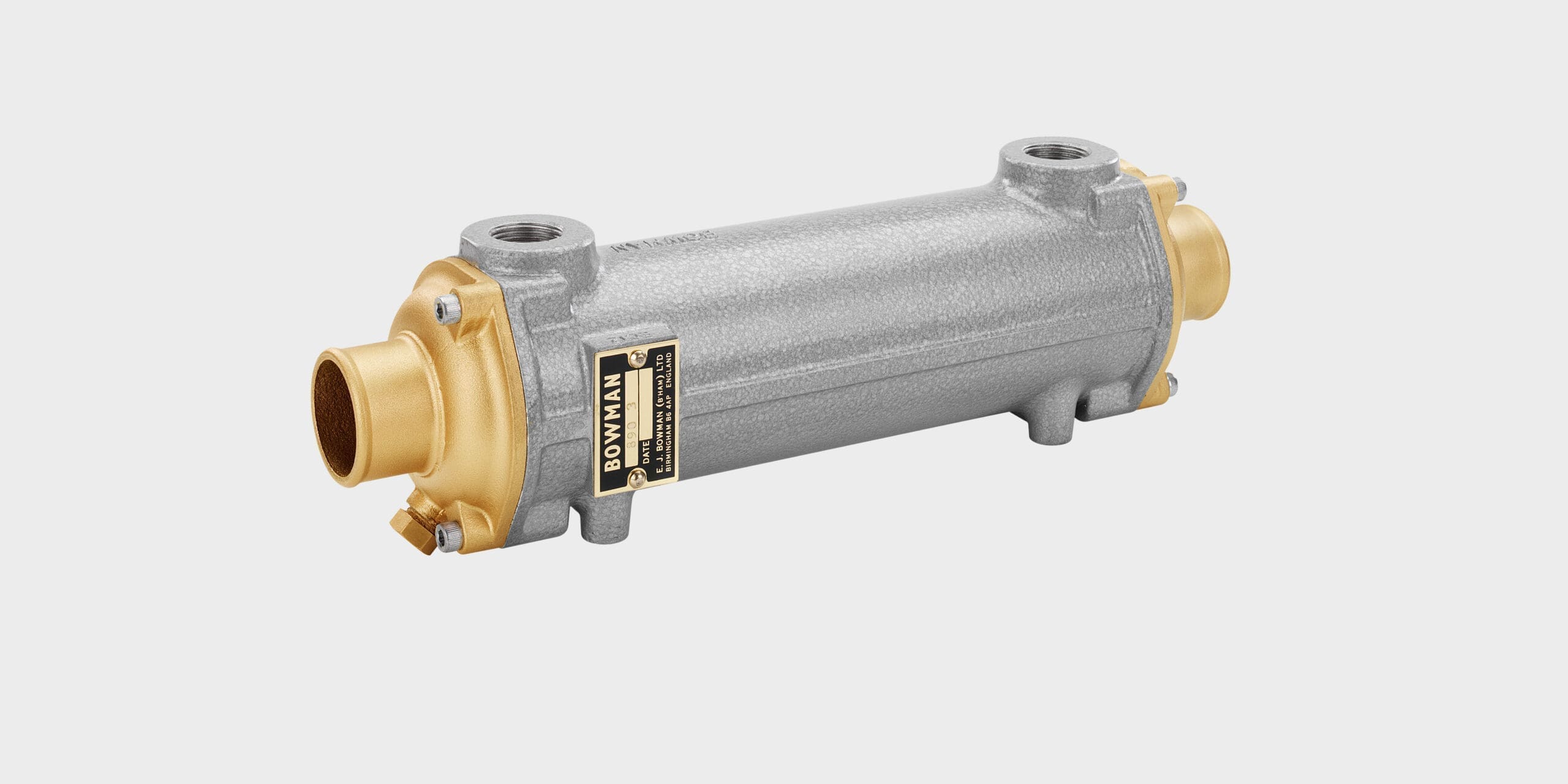

Many applications require stainless steel shell and tube heat exchangers and Bowman provide a standard range of units that are suitable for cooling or heating a variety of fluids.

Bowman swimming pool heat exchangers are renowned for reliability and efficiency. Whether heating your pool with a traditional boiler or a renewable energy source, Bowman is the obvious choice.

Premium quality heat exchangers and oil coolers for precise temperature control of engines under test cell development conditions.

Recovering waste heat energy from engine powered generating sets for biogas, diesel and natural gas applications up to 1 MW.

Efficient cooling for stationary / land-based engines where air cooling is either unavailable or inappropriate.

The reliable solution for cooling Electric & Hybrid Marine Propulsion Systems.

A comprehensive oil cooling solution for industrial hydraulic control systems, plus high temperature and mining applications.

A complete solution for cooling complex on-board hydraulic equipment, including thruster and stabiliser systems.

The complete cooling solution for marine engine propulsion, including the latest electric and hybrid systems.

An energy efficient solution for heating hot tubs and swim spas faster, significantly reducing heat-up time for guest change-over periods.

Quality heat exchangers for efficient swimming pool heating, using boiler or renewable energy heat sources.

Heats spas and hot tubs extremely fast, reducing energy costs

Solvent weld end covers with thermostat pocket

Salt water and mineral rich fresh water compatible

Easy disassembly for routine maintenance

Full 10 year warranty on titanium materials

Heats spas and hot tubs extremely fast, reducing energy costs

Solvent weld end covers with thermostat pocket

Salt water and mineral rich fresh water compatible

Easy disassembly for routine maintenance

Full 10 year warranty on titanium materials

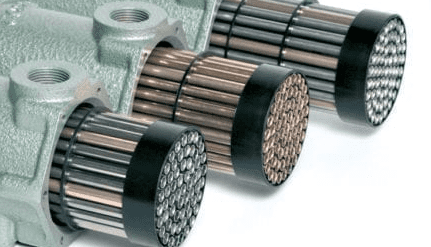

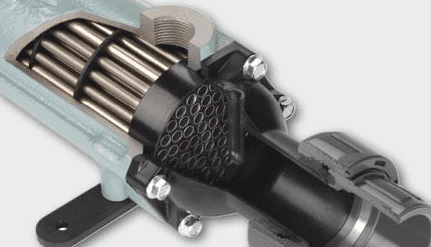

The modular design means that end covers on all models are easily removable, enabling the tube stack to be easily extracted from the outer ‘shell’ ensuring all maintenance requirements are simple and straightforward.

The faster a pool gets to the required temperature, the lower the energy costs! Bowman units heat pools up to three times faster and the result is reduced energy costs and improved pool availability.

The tube stack is packed with tubes and internal baffles to provide the largest and most effective surface area, enabling the unit to heat pools considerably faster than some competitors’ products.

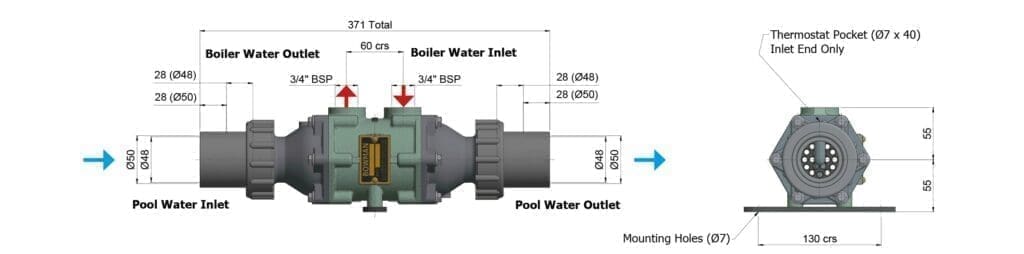

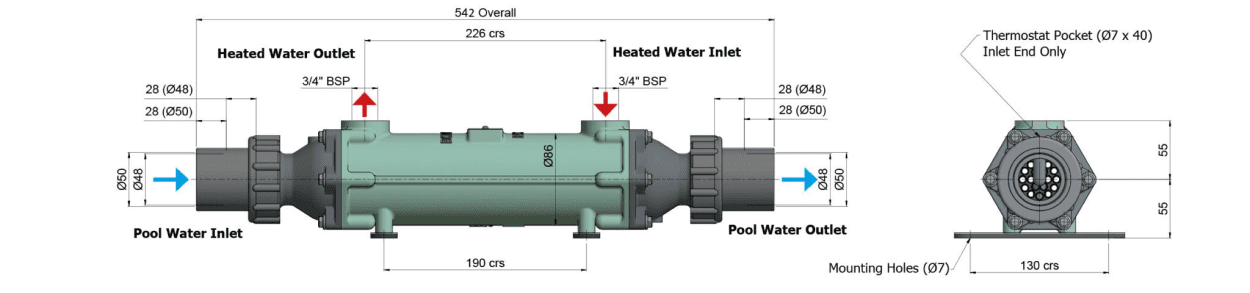

Note – All dimensions in mm (except threaded connectors)

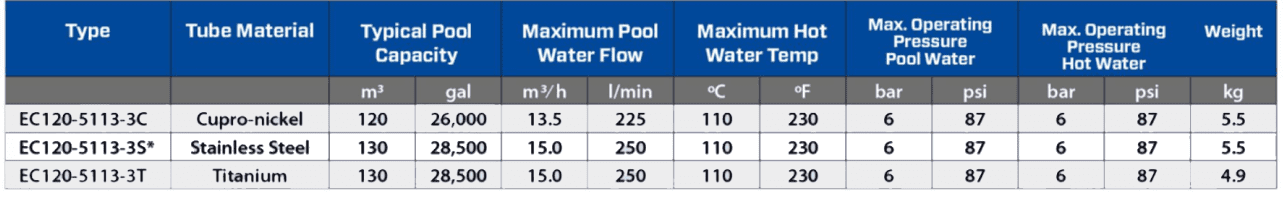

*Not suitable for use on pools fitted with salt water chlorinators or salt water pools.

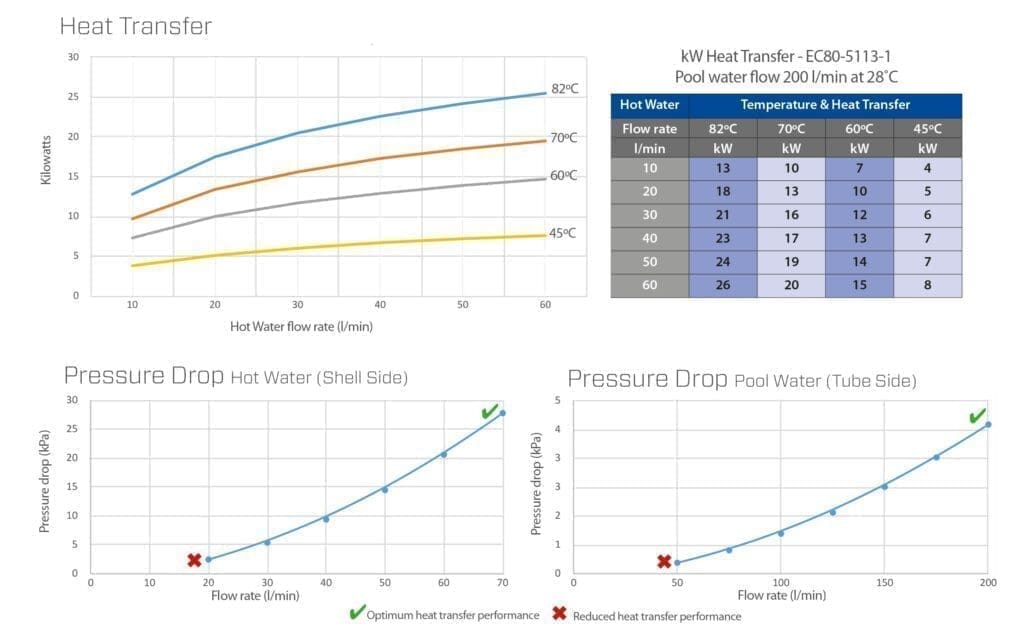

As the graphs and table above illustrate, providing the right water flow volume is vital to the performance of the heat exchanger. If the flow rate of either the hot water supply, or the pool water circuit is too low, the heat exchanger will not perform at its designed efficiency and will be unable to transfer all the available heat energy in to the pool water. For more information, please read: Why doesn’t my pool heat up faster?

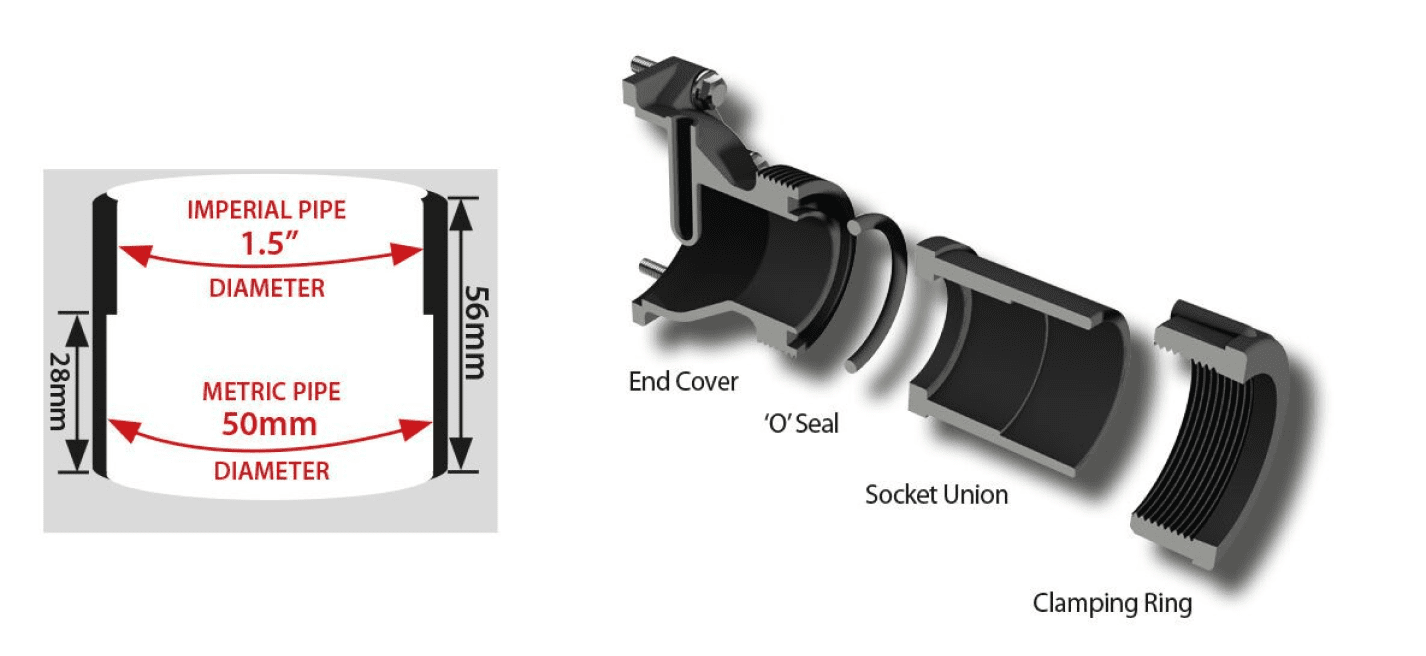

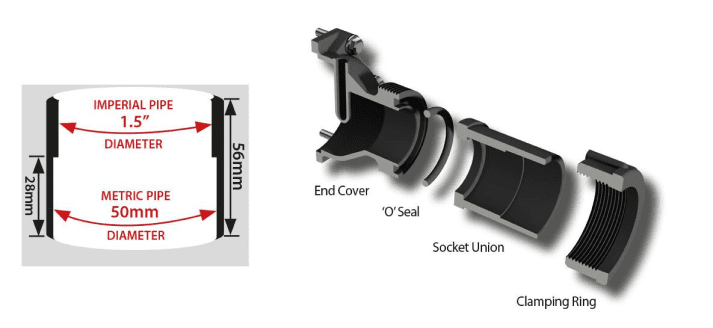

The EC80-5113-1 is supplied with ‘Universal Fit’ composite end covers, designed for use with either 1.5” nominal pipe size (48mm O/D) or metric 50mm O/D pool pipework. The ‘socket union’ component enables either diameter to be accommodated, as shown on the following cross section illustration.

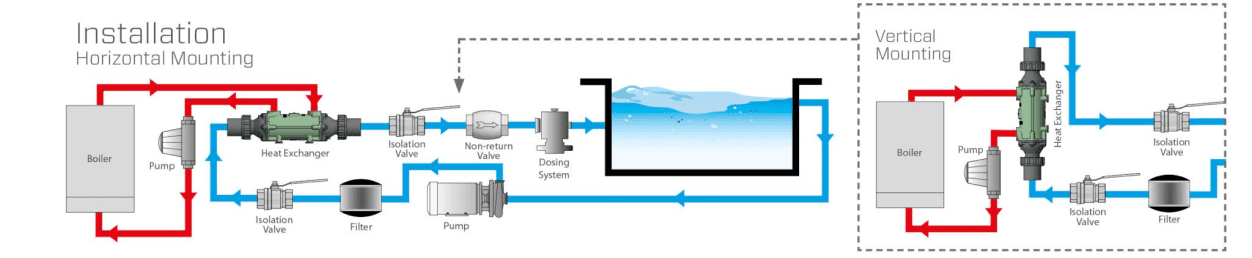

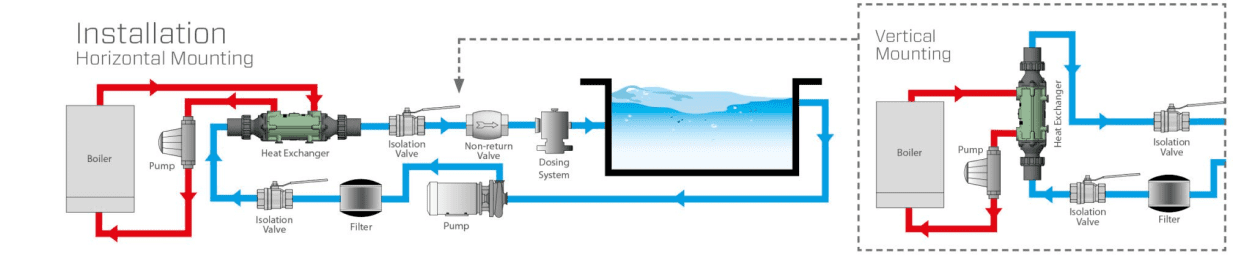

Refer to the following diagram for how to install the heat exchanger in the pool system. The heat exchanger can be mounted either horizontally or vertically as per the schematic.

If an automatic dosing system is added, it must be installed after the heat exchanger on the return to the pool.

Note – All dimensions in mm (except threaded connectors)

*Not suitable for use on pools fitted with salt water chlorinators or salt water pools.

As the graphs and table above illustrate, providing the right water flow volume is vital to the performance of the heat exchanger. If the flow rate of either the hot water supply, or the pool water circuit is too low, the heat exchanger will not perform at its designed efficiency and will be unable to transfer all the available heat energy in to the pool water. For more information, please read: Why doesn’t my pool heat up faster?

The EC120-5113-3 is supplied with ‘Universal Fit’ composite end covers, designed for use with either 1.5” nominal pipe size (48mm O/D) or metric 50mm O/D pool pipework. The ‘socket union’ component enables either diameter to be accommodated, as shown on the following cross section illustration.

Refer to the following diagram for how to install the heat exchanger in the pool system. The heat exchanger can be mounted either horizontally or vertically as per the schematic.

If an automatic dosing system is added, it must be installed after the heat exchanger on the return to the pool.

Most hot tubs are supplied with an integral electric heater, usually around 3 kW output, depending on the water capacity. However, more recently, there has been a growing trend to use gas heating via an external boiler as this is faster at heating up the water compared to electric. This means when you are not using the hot tub, you can keep it at a lower temperature, or even switch the heating off completely, because it won’t take long to bring it up to the temperature when you are ready to use it.

The main reason is the length of time required to heat a hot tub with an electric heater – typically up to 24 hours, using cold water. To speed things up, some owners ‘pre-fill’ their tub with hot water from a boiler, but even this can require a further 6 to 10 hours of heating to achieve the required 38-40 °C temperature.

Whilst many domestic users were prepared to put up with the inconvenience, commercial users such as holiday parks, could not!

The demand for hot tubs when booking holiday accommodation has risen dramatically and is now the second most requested guest facility. To meet this demand, holiday venues had to find a faster way of heating them, due to guest changeover periods. Typically, there is only around 4-5 hours available to drain, clean, re-fill and heat up a hot tub before new guests arrive.

The solution was relatively simple – use an external heat source such as a gas boiler and simply bypass the hot tub’s electric heater. To enable this, a heat exchanger is required to transfer heat from the boiler water to the hot tub water. It’s exactly the same principle used for most swimming pools, but just on a smaller scale.

Bowman developed an ultra-compact heat exchanger that could be installed in the hot tub’s pipework and the result was hot tubs heated in 3-4 hours using cold water, or in around 1 hour using pre-heated water.

There was also another benefit. Heating hot tubs with electricity can be very expensive. By switching to gas boiler heating, many users reported a significant reduction in the energy costs – some as much as £500.00 per hot tub!

As their name suggests, hot tubs require a lot of heat to achieve and maintain the 38°C to 40°C water temperature they usually run at.

Most hot tubs are supplied as standard with an electric heater already installed. This usually takes many hours to heat a typical 1,400 litre hot tub from ambient water temperature to normal operating temperature, and as electricity is one of the most expensive ways of heating, it’s not surprising that many users find their electricity costs rise sharply!

A more efficient solution is to heat the hot tub from an external heat source, such as a gas boiler. Usually, this can be done by connecting pipework from the hot tub to the boiler, in a similar way to adding a new radiator to a new room in a home.

The only difference is the hot tub requires a heat exchanger to act as an interface to keep the pool and the boiler water separate from each other. Installing the heat exchanger into the pool water circuit and connecting to the boiler is straightforward, though a plumber may be required to install.

Once the hot tub is being heated from the house boiler, many users notice how much quicker the water temperature increases and in many cases, the hot tub can be ready to use in just 2 -3 hours of heating, which is a real bonus, as it significantly reduces the energy used and, as gas heating costs are much lower than electricity, energy costs are significantly reduced too!

Bowman has been one of the pioneers in providing hot tub heating via heat exchangers and have a comprehensive range of products for this specific application. For more information on Bowman Hot Tub Heat Exchangers

Bowman and Rinnai provide the perfect heating solution for an Australian roof top pool – where winter temperatures can be surprisingly cool!

Six Bowman heat exchangers have been installed at the recently opened Gold’s Gym, Amman, Jordan, to heat two half Olympic-sized swimming pools.

How Bowman heat exchangers are helping this internationally renowned golf destination reduce energy costs and CO₂ emissions.

Bowman heat exchangers are playing an important role in the success of a flagship hotel on the Black Sea coast in Georgia.

If you have a specific enquiry or would like to talk to one of our technical sales engineers, you can contact us by phone or email, using the contact details below. For more general enquiries, simply fill in and return the contact form for a fast response.

Tel: +44 (0)121 359 5401

E-mail: [email protected]

A network of authorised, international Bowman distributors, who hold product stocks and provide local service, is also available.