Rooftop swimming pool heating in Perth, WA

Bowman and Rinnai provide the perfect heating solution for an Australian roof top pool – where winter temperatures can be surprisingly cool!

Used to cool the hot, compressed air from the turbo before it reaches the engine, the intercoolers improve engine efficiency and reduce emissions for marine and land-based stationary engines.

Exhaust gas heat exchangers are designed to recover waste heat energy from the exhaust stream of reciprocating engine powered generating sets.

Bowman 'copper free' fuel coolers are compact, highly efficient heat exchangers suitable for fuel conditioning rigs in the automotive testing industry.

Engine coolant header tank heat exchangers for marine propulsion, gensets or stationary land-based engines.

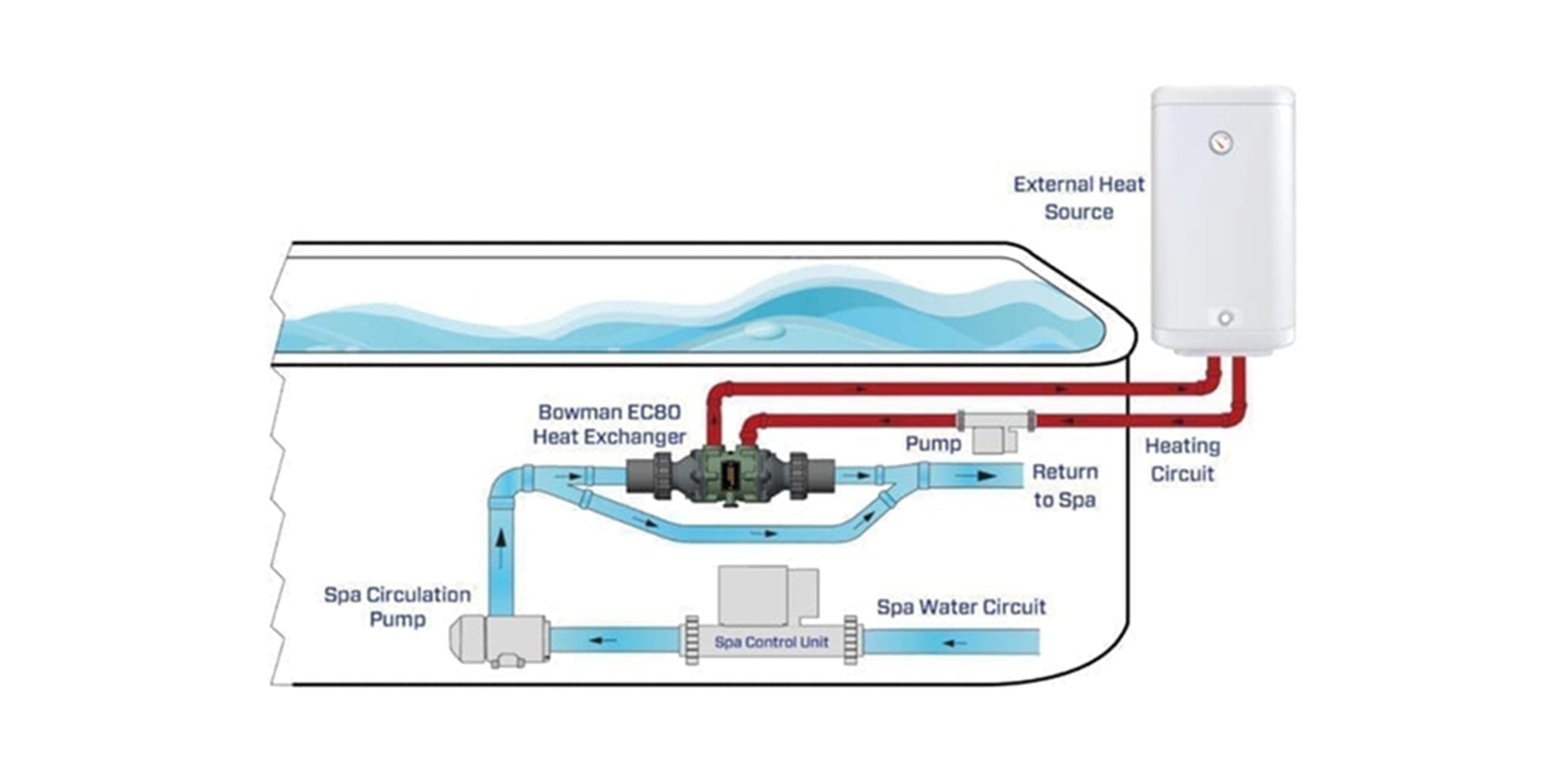

Bowman EC 80-5113-1T heat exchangers provide a new solution for heating spas and hot tubs in just a fraction of the time taken by traditional electric heaters.

Highly efficient heat transfer solutions for cooling marine, land-based and underground hydraulic systems.

Bowman inline plate heat exchangers are a compact, economical solution for high efficiency heat transfer.

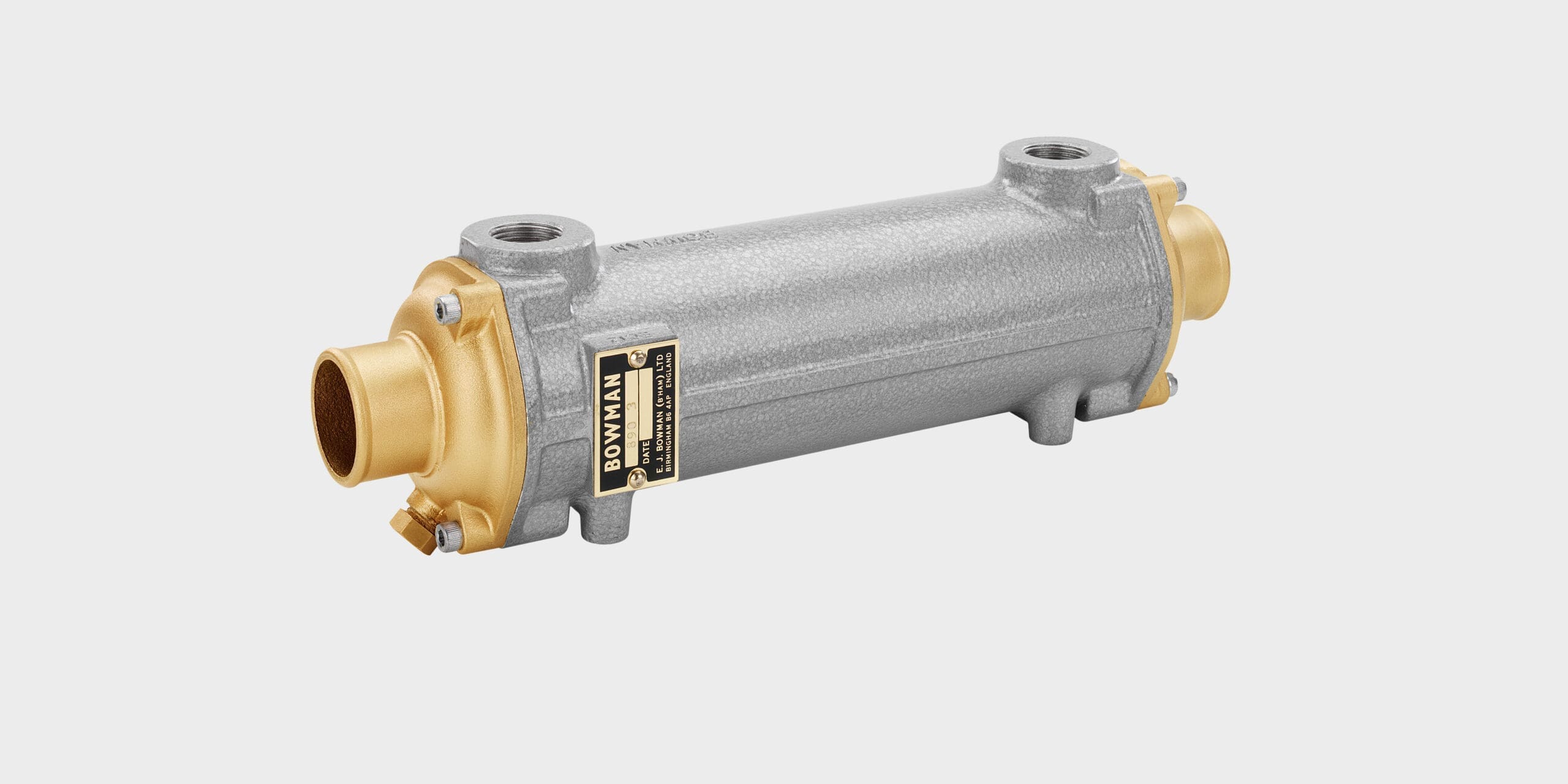

Bespoke cooling solutions for a range of popular marine engines from major OEMs, including coolant heat exchangers, charge air coolers, plus combined heat exchangers and exhaust manifolds, suitable for cooling marine engines up to 1 MW.

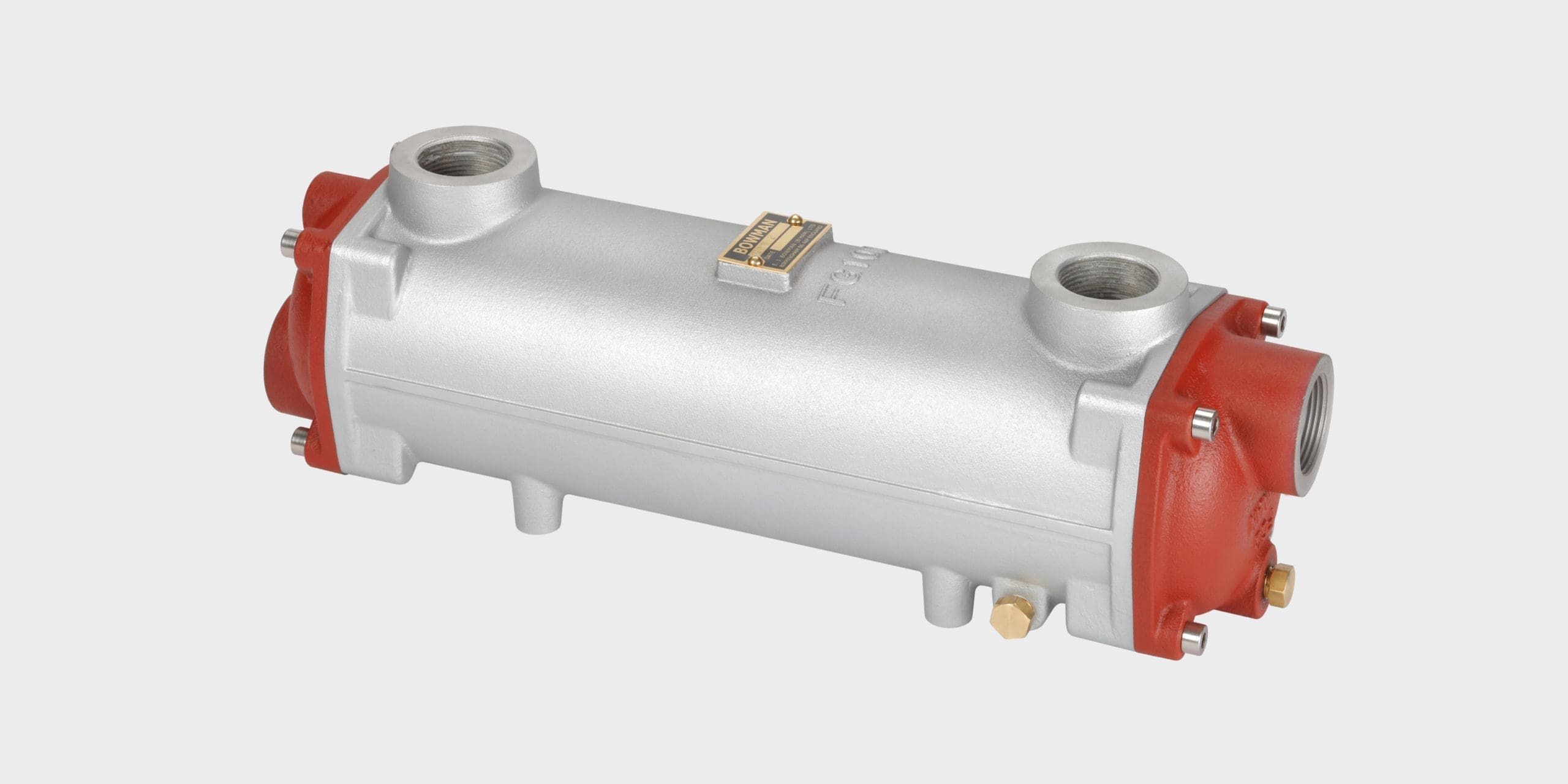

Bowman has a range of highly efficient oil coolers designed for marine and industrial engines and transmissions.

Efficient heat exchangers for cooling electric marine motors, hydrogen fuel cells, battery packs, chargers, AC-DC converters, DC-DC converters, inverters and associated equipment for electric and hybrid marine propulsion and charging systems.

Highly efficient heat transfer solutions for cooling a variety of applications where air and fluids need to be cooled by fluids.

Many applications require stainless steel shell and tube heat exchangers and Bowman provide a standard range of units that are suitable for cooling or heating a variety of fluids.

Bowman swimming pool heat exchangers are renowned for reliability and efficiency. Whether heating your pool with a traditional boiler or a renewable energy source, Bowman is the obvious choice.

Premium quality heat exchangers and oil coolers for precise temperature control of engines under test cell development conditions.

Recovering waste heat energy from engine powered generating sets for biogas, diesel and natural gas applications up to 1 MW.

Efficient cooling for stationary / land-based engines where air cooling is either unavailable or inappropriate.

The reliable solution for cooling Electric & Hybrid Marine Propulsion Systems.

A comprehensive oil cooling solution for industrial hydraulic control systems, plus high temperature and mining applications.

A complete solution for cooling complex on-board hydraulic equipment, including thruster and stabiliser systems.

The complete cooling solution for marine engine propulsion, including the latest electric and hybrid systems.

An energy efficient solution for heating hot tubs and swim spas faster, significantly reducing heat-up time for guest change-over periods.

Quality heat exchangers for efficient swimming pool heating, using boiler or renewable energy heat sources.

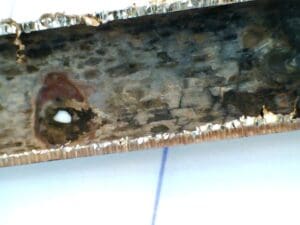

Water left inside for prolonged periods can ruin a heat exchanger. Here we show how to eliminate the danger of stagnant water contamination.

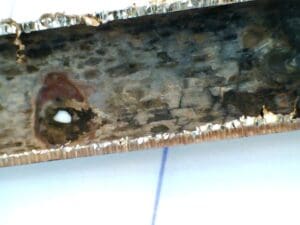

Stagnant water – who needs it? It’s smelly and unsightly in fresh water ponds, but inside your heat exchanger, it’s potentially lethal!

The problem is, this ‘silent killer’ does its worst out of sight, so, unless you’re aware of the danger and take appropriate action, you may not even realise there’s a problem – until it’s too late!

However, there are some simple steps you can take to protect your heat exchanger; but first, let’s examine the cause of the problem.

Copper-nickel alloy (also referred to as ‘cupronickel’) is one of the primary materials used for the tube stack (or bundle) in a shell and tube heat exchanger. It’s extremely popular for marine cooling applications, as it provides excellent resistance to corrosive cooling media such as sea water, which is achieved by the formulation of a thin protective ‘film’ over the surface of the metal. This film starts to develop during the first few days of contact with ‘clean oxygenated sea water’, though it takes a further 3 months for it to fully develop. So, it’s extremely important that the copper-nickel tubes are only exposed to clean oxygenated sea water during this period, to ensure maximum corrosion resistance.

Problems can occur, if a cooling system undergoes commissioning and is then left for periods of time with the heat exchangers undrained, as it allows oxygenated sea water to ‘stagnate’ inside the tubes, creating ideal conditions for harmful bacteria to build up.

In many harbours and estuaries, anaerobic bacteria thrives in the sea water and in this high oxygen demand environment, sulphide ions, produced by sulphide generating bacteria are in abundance. This can be bad news for recently installed copper-nickel alloy, as unless the metal has gone through a full ‘conditioning’ process, using clean oxygenated water, it is highly likely the tubes’ internal protective oxide film will be much weaker, due to it being produced in the presence of sulphide contamination, and thus liable to create the conditions for accelerated corrosion.

In many harbours and estuaries, anaerobic bacteria thrives in the sea water and in this high oxygen demand environment, sulphide ions, produced by sulphide generating bacteria are in abundance. This can be bad news for recently installed copper-nickel alloy, as unless the metal has gone through a full ‘conditioning’ process, using clean oxygenated water, it is highly likely the tubes’ internal protective oxide film will be much weaker, due to it being produced in the presence of sulphide contamination, and thus liable to create the conditions for accelerated corrosion.

However, it’s relatively straightforward to create a monitoring and maintenance regime for a new heat exchanger during the critical first three months of commissioning a cooling system and provided these steps are followed, the heat exchanger should operate at optimum efficiency over its normal life expectancy:

1: Ensure only ‘clean oxygenated sea water’ is used for cooling during the initial three months of operation to enable the full layer of protective ‘film’ to be built up on the internal tube surfaces.

2: Always drain down the sea water cooling circuit, if the boat is to be laid up for any extended periods of time.

3: After draining the sea water circuit, remove the heat exchanger* and flush through with either clean oxygenated sea water or fresh water – depending on what is readily available.

4: Carefully dry the heat exchanger before refitting* it back into the cooling circuit.

*If the end covers have been removed, always reassemble using new ‘O’ rings.

Whilst the points given above are considered ‘best practice’ for ensuring long, reliable operation of the heat exchanger, there are certain circumstances where stagnant water can’t be avoided. In these applications, Bowman recommend changing the tube stack material to titanium, which is an even more durable material, offering higher levels of corrosion resistance, together with a 10-year warranty.

Water left inside for prolonged periods can ruin a heat exchanger. Here we show how to eliminate the danger of stagnant water contamination.

Stagnant water – who needs it? It’s smelly and unsightly in fresh water ponds, but inside your heat exchanger, it’s potentially lethal!

The problem is, this ‘silent killer’ does its worst out of sight, so, unless you’re aware of the danger and take appropriate action, you may not even realise there’s a problem – until it’s too late!

However, there are some simple steps you can take to protect your heat exchanger; but first, let’s examine the cause of the problem.

Copper-nickel alloy (also referred to as ‘cupronickel’) is one of the primary materials used for the tube stack (or bundle) in a shell and tube heat exchanger. It’s extremely popular for marine cooling applications, as it provides excellent resistance to corrosive cooling media such as sea water, which is achieved by the formulation of a thin protective ‘film’ over the surface of the metal. This film starts to develop during the first few days of contact with ‘clean oxygenated sea water’, though it takes a further 3 months for it to fully develop. So, it’s extremely important that the copper-nickel tubes are only exposed to clean oxygenated sea water during this period, to ensure maximum corrosion resistance.

Problems can occur, if a cooling system undergoes commissioning and is then left for periods of time with the heat exchangers undrained, as it allows oxygenated sea water to ‘stagnate’ inside the tubes, creating ideal conditions for harmful bacteria to build up.

In many harbours and estuaries, anaerobic bacteria thrives in the sea water and in this high oxygen demand environment, sulphide ions, produced by sulphide generating bacteria are in abundance. This can be bad news for recently installed copper-nickel alloy, as unless the metal has gone through a full ‘conditioning’ process, using clean oxygenated water, it is highly likely the tubes’ internal protective oxide film will be much weaker, due to it being produced in the presence of sulphide contamination, and thus liable to create the conditions for accelerated corrosion.

In many harbours and estuaries, anaerobic bacteria thrives in the sea water and in this high oxygen demand environment, sulphide ions, produced by sulphide generating bacteria are in abundance. This can be bad news for recently installed copper-nickel alloy, as unless the metal has gone through a full ‘conditioning’ process, using clean oxygenated water, it is highly likely the tubes’ internal protective oxide film will be much weaker, due to it being produced in the presence of sulphide contamination, and thus liable to create the conditions for accelerated corrosion.

However, it’s relatively straightforward to create a monitoring and maintenance regime for a new heat exchanger during the critical first three months of commissioning a cooling system and provided these steps are followed, the heat exchanger should operate at optimum efficiency over its normal life expectancy:

1: Ensure only ‘clean oxygenated sea water’ is used for cooling during the initial three months of operation to enable the full layer of protective ‘film’ to be built up on the internal tube surfaces.

2: Always drain down the sea water cooling circuit, if the boat is to be laid up for any extended periods of time.

3: After draining the sea water circuit, remove the heat exchanger* and flush through with either clean oxygenated sea water or fresh water – depending on what is readily available.

4: Carefully dry the heat exchanger before refitting* it back into the cooling circuit.

*If the end covers have been removed, always reassemble using new ‘O’ rings.

Whilst the points given above are considered ‘best practice’ for ensuring long, reliable operation of the heat exchanger, there are certain circumstances where stagnant water can’t be avoided. In these applications, Bowman recommend changing the tube stack material to titanium, which is an even more durable material, offering higher levels of corrosion resistance, together with a 10-year warranty.

Bowman and Rinnai provide the perfect heating solution for an Australian roof top pool – where winter temperatures can be surprisingly cool!

Six Bowman heat exchangers have been installed at the recently opened Gold’s Gym, Amman, Jordan, to heat two half Olympic-sized swimming pools.

How Bowman heat exchangers are helping this internationally renowned golf destination reduce energy costs and CO₂ emissions.

Bowman heat exchangers are playing an important role in the success of a flagship hotel on the Black Sea coast in Georgia.

Bowman and Rinnai provide the perfect heating solution for an Australian roof top pool – where winter temperatures can be surprisingly cool!

Six Bowman heat exchangers have been installed at the recently opened Gold’s Gym, Amman, Jordan, to heat two half Olympic-sized swimming pools.

How Bowman heat exchangers are helping this internationally renowned golf destination reduce energy costs and CO₂ emissions.

Bowman heat exchangers are playing an important role in the success of a flagship hotel on the Black Sea coast in Georgia.