Rooftop swimming pool heating in Perth, WA

Bowman and Rinnai provide the perfect heating solution for an Australian roof top pool – where winter temperatures can be surprisingly cool!

Used to cool the hot, compressed air from the turbo before it reaches the engine, the intercoolers improve engine efficiency and reduce emissions for marine and land-based stationary engines.

Exhaust gas heat exchangers are designed to recover waste heat energy from the exhaust stream of reciprocating engine powered generating sets.

Bowman 'copper free' fuel coolers are compact, highly efficient heat exchangers suitable for fuel conditioning rigs in the automotive testing industry.

Engine coolant header tank heat exchangers for marine propulsion, gensets or stationary land-based engines.

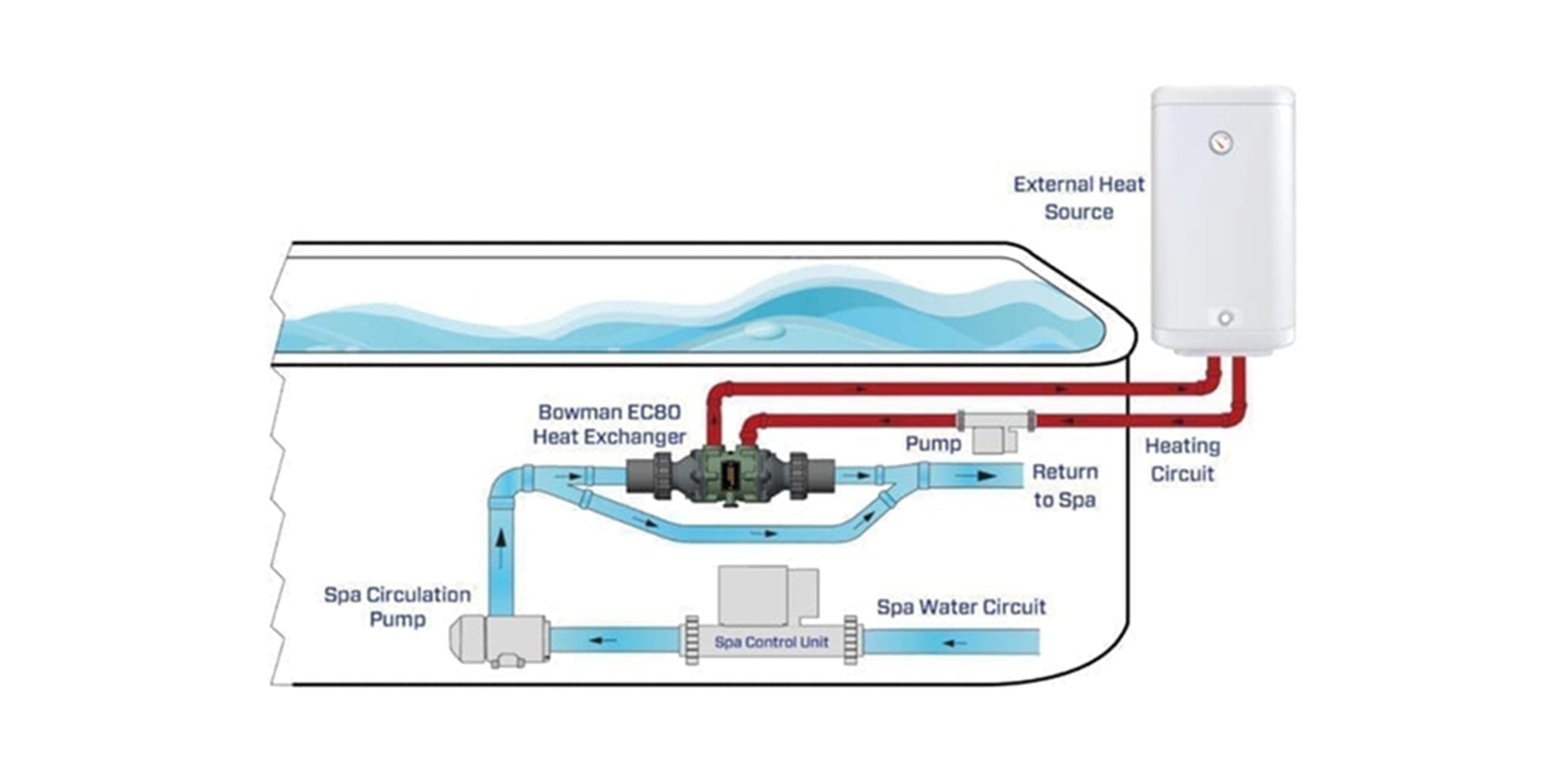

Bowman EC 80-5113-1T heat exchangers provide a new solution for heating spas and hot tubs in just a fraction of the time taken by traditional electric heaters.

Highly efficient heat transfer solutions for cooling marine, land-based and underground hydraulic systems.

Bowman inline plate heat exchangers are a compact, economical solution for high efficiency heat transfer.

Bespoke cooling solutions for a range of popular marine engines from major OEMs, including coolant heat exchangers, charge air coolers, plus combined heat exchangers and exhaust manifolds, suitable for cooling marine engines up to 1 MW.

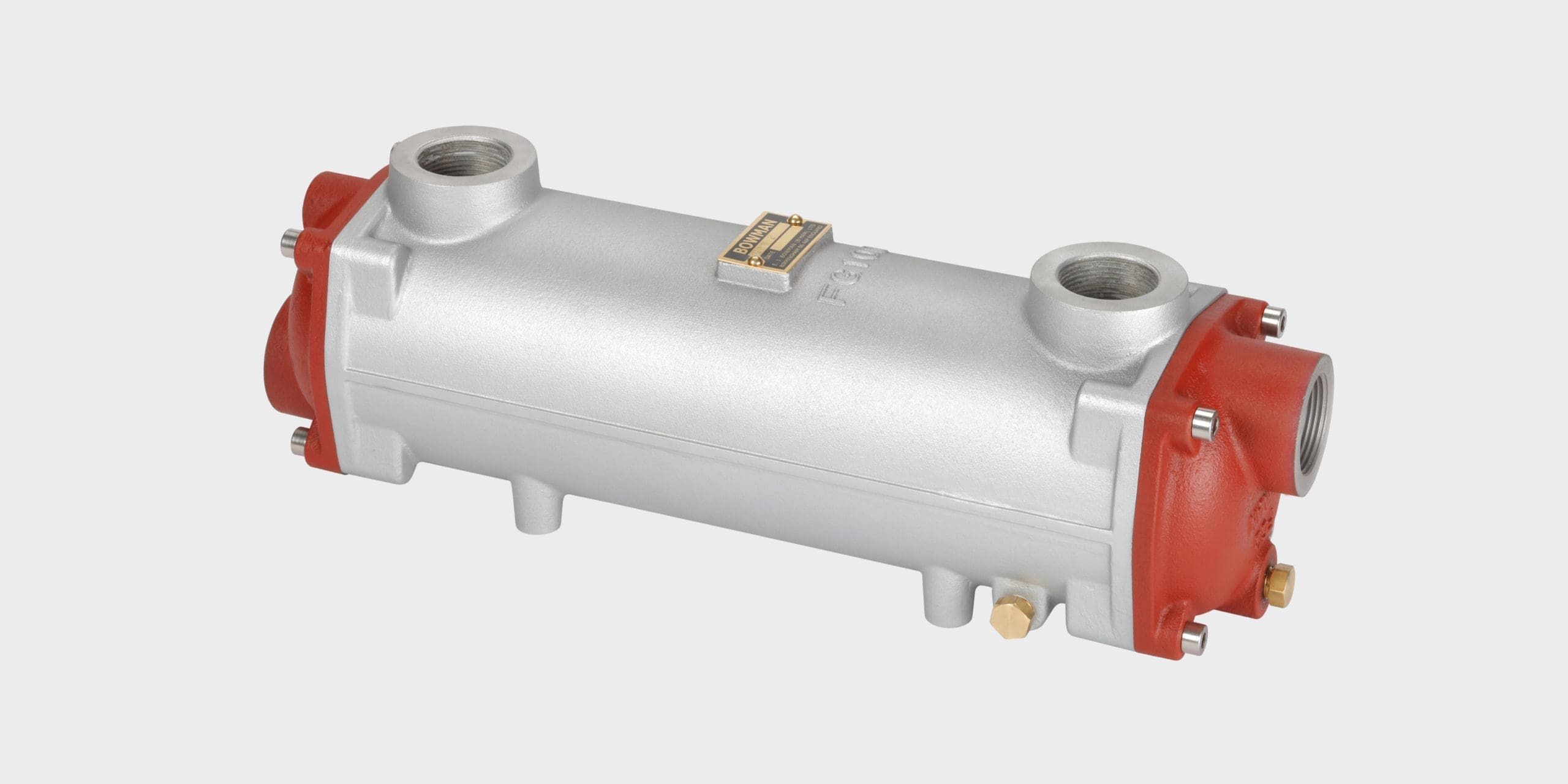

Bowman has a range of highly efficient oil coolers designed for marine and industrial engines and transmissions.

Efficient heat exchangers for cooling electric marine motors, hydrogen fuel cells, battery packs, chargers, AC-DC converters, DC-DC converters, inverters and associated equipment for electric and hybrid marine propulsion and charging systems.

Highly efficient heat transfer solutions for cooling a variety of applications where air and fluids need to be cooled by fluids.

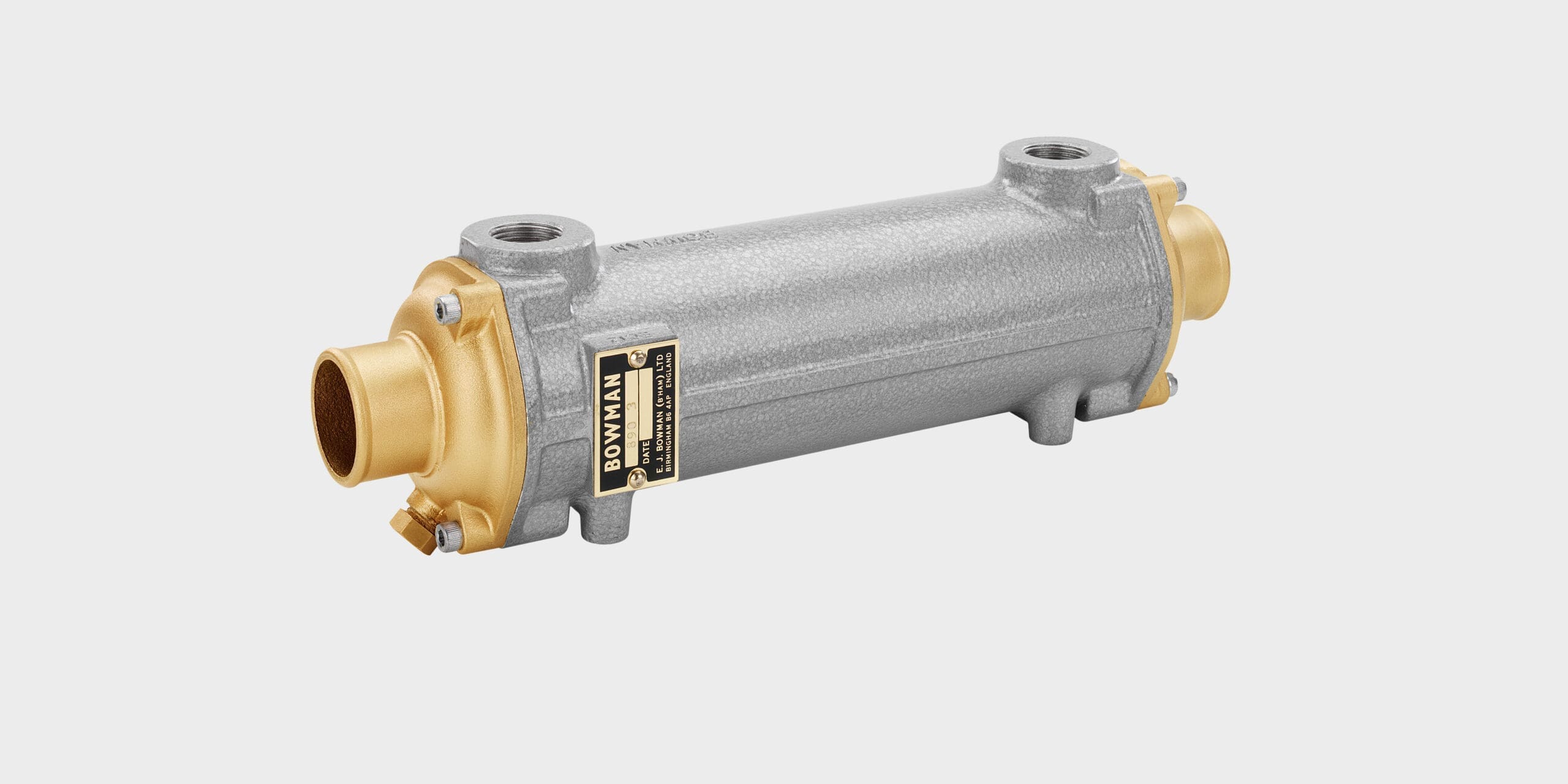

Many applications require stainless steel shell and tube heat exchangers and Bowman provide a standard range of units that are suitable for cooling or heating a variety of fluids.

Bowman swimming pool heat exchangers are renowned for reliability and efficiency. Whether heating your pool with a traditional boiler or a renewable energy source, Bowman is the obvious choice.

Premium quality heat exchangers and oil coolers for precise temperature control of engines under test cell development conditions.

Recovering waste heat energy from engine powered generating sets for biogas, diesel and natural gas applications up to 1 MW.

Efficient cooling for stationary / land-based engines where air cooling is either unavailable or inappropriate.

The reliable solution for cooling Electric & Hybrid Marine Propulsion Systems.

A comprehensive oil cooling solution for industrial hydraulic control systems, plus high temperature and mining applications.

A complete solution for cooling complex on-board hydraulic equipment, including thruster and stabiliser systems.

The complete cooling solution for marine engine propulsion, including the latest electric and hybrid systems.

An energy efficient solution for heating hot tubs and swim spas faster, significantly reducing heat-up time for guest change-over periods.

Quality heat exchangers for efficient swimming pool heating, using boiler or renewable energy heat sources.

Keeping heat exchanger and oil cooler cooling tubes clean and clear from debris is a major issue. Bowman’s Double Seal Retaining Flange offers an easy solution.

The well-documented problems of single use plastics that find their way into in our oceans and waterways is well-known and has created the need to employ a more rigorous cleaning regime for hydraulic oil coolers to ensure the central tube core doesn’t become blocked by plastic residue, as well as other water-borne debris such as algae, oil deposits and general detritus.

Whilst this issue is understandably a growing concern in the marine industry, inland watercourses can suffer similarly, so that any process plant drawing water from rivers or reservoirs to cool hydraulic equipment, could find they experience similar problems.

Bowman hydraulic oil coolers are manufactured to a proven ‘shell and tube’ design which enables the tube stack to be easily withdrawn for cleaning, simply by removing a series of screws on the end covers.

However, cleaning hydraulic oil coolers can create a potentially dangerous hazard, as even when the oil has been drained from the cooler, the unit may still contain some oil residue inside. So, removing the tube stack could result in oil being spilt on to the deck or floor, creating the potential for slip or fall hazards for operatives working on the unit.

Recognising this problem, Bowman have developed a solution that not only enables the tubes to be cleaned without removing the tube stack, but can also reduce the amount of time required for cleaning and maintenance.

Known as the ‘Double Seal Retaining Flange’ or DSRF, it is a clever piece of design, which fits between the oil cooler body and a standard end cover. It enables the end cover to be removed for cleaning or inspection of the cooling water side, without disturbing the oil side.

In fact, the DSRF completely eliminates the need to drain the hydraulic fluid during cleaning which is an additional benefit as it not only saves time but also reduces the potential for contamination getting in to the oil, whilst it is stored during cleaning.

In fact, the DSRF completely eliminates the need to drain the hydraulic fluid during cleaning which is an additional benefit as it not only saves time but also reduces the potential for contamination getting in to the oil, whilst it is stored during cleaning.

The DSRF unit is currently available for Bowman’s GL, GK, JK and PK hydraulic oil cooler ranges, with versions for both sea water or fresh water cooling media.

For full product information, contact the technical sales team on +44 (0)121 359 5401 or email [email protected]

Keeping heat exchanger and oil cooler cooling tubes clean and clear from debris is a major issue. Bowman’s Double Seal Retaining Flange offers an easy solution.

The well-documented problems of single use plastics that find their way into in our oceans and waterways is well-known and has created the need to employ a more rigorous cleaning regime for hydraulic oil coolers to ensure the central tube core doesn’t become blocked by plastic residue, as well as other water-borne debris such as algae, oil deposits and general detritus.

Whilst this issue is understandably a growing concern in the marine industry, inland watercourses can suffer similarly, so that any process plant drawing water from rivers or reservoirs to cool hydraulic equipment, could find they experience similar problems.

Bowman hydraulic oil coolers are manufactured to a proven ‘shell and tube’ design which enables the tube stack to be easily withdrawn for cleaning, simply by removing a series of screws on the end covers.

However, cleaning hydraulic oil coolers can create a potentially dangerous hazard, as even when the oil has been drained from the cooler, the unit may still contain some oil residue inside. So, removing the tube stack could result in oil being spilt on to the deck or floor, creating the potential for slip or fall hazards for operatives working on the unit.

Recognising this problem, Bowman have developed a solution that not only enables the tubes to be cleaned without removing the tube stack, but can also reduce the amount of time required for cleaning and maintenance.

Known as the ‘Double Seal Retaining Flange’ or DSRF, it is a clever piece of design, which fits between the oil cooler body and a standard end cover. It enables the end cover to be removed for cleaning or inspection of the cooling water side, without disturbing the oil side.

In fact, the DSRF completely eliminates the need to drain the hydraulic fluid during cleaning which is an additional benefit as it not only saves time but also reduces the potential for contamination getting in to the oil, whilst it is stored during cleaning.

In fact, the DSRF completely eliminates the need to drain the hydraulic fluid during cleaning which is an additional benefit as it not only saves time but also reduces the potential for contamination getting in to the oil, whilst it is stored during cleaning.

The DSRF unit is currently available for Bowman’s GL, GK, JK and PK hydraulic oil cooler ranges, with versions for both sea water or fresh water cooling media.

For full product information, contact the technical sales team on +44 (0)121 359 5401 or email [email protected]

Bowman and Rinnai provide the perfect heating solution for an Australian roof top pool – where winter temperatures can be surprisingly cool!

Six Bowman heat exchangers have been installed at the recently opened Gold’s Gym, Amman, Jordan, to heat two half Olympic-sized swimming pools.

How Bowman heat exchangers are helping this internationally renowned golf destination reduce energy costs and CO₂ emissions.

Bowman heat exchangers are playing an important role in the success of a flagship hotel on the Black Sea coast in Georgia.

Bowman and Rinnai provide the perfect heating solution for an Australian roof top pool – where winter temperatures can be surprisingly cool!

Six Bowman heat exchangers have been installed at the recently opened Gold’s Gym, Amman, Jordan, to heat two half Olympic-sized swimming pools.

How Bowman heat exchangers are helping this internationally renowned golf destination reduce energy costs and CO₂ emissions.

Bowman heat exchangers are playing an important role in the success of a flagship hotel on the Black Sea coast in Georgia.