Rooftop swimming pool heating in Perth, WA

Bowman and Rinnai provide the perfect heating solution for an Australian roof top pool – where winter temperatures can be surprisingly cool!

Used to cool the hot, compressed air from the turbo before it reaches the engine, the intercoolers improve engine efficiency and reduce emissions for marine and land-based stationary engines.

Exhaust gas heat exchangers are designed to recover waste heat energy from the exhaust stream of reciprocating engine powered generating sets.

Bowman 'copper free' fuel coolers are compact, highly efficient heat exchangers suitable for fuel conditioning rigs in the automotive testing industry.

Engine coolant header tank heat exchangers for marine propulsion, gensets or stationary land-based engines.

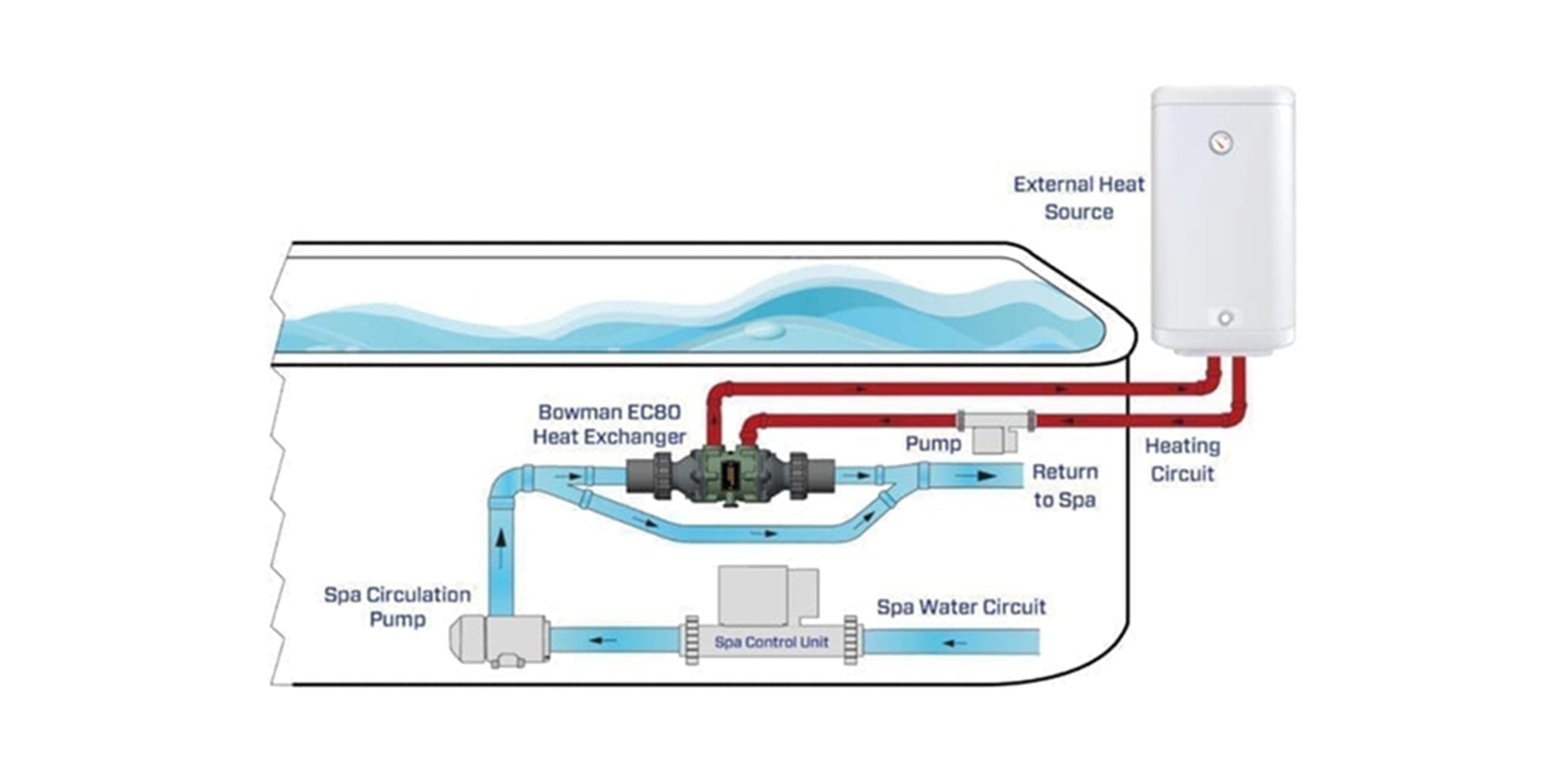

Bowman EC 80-5113-1T heat exchangers provide a new solution for heating spas and hot tubs in just a fraction of the time taken by traditional electric heaters.

Highly efficient heat transfer solutions for cooling marine, land-based and underground hydraulic systems.

Bowman inline plate heat exchangers are a compact, economical solution for high efficiency heat transfer.

Bespoke cooling solutions for a range of popular marine engines from major OEMs, including coolant heat exchangers, charge air coolers, plus combined heat exchangers and exhaust manifolds, suitable for cooling marine engines up to 1 MW.

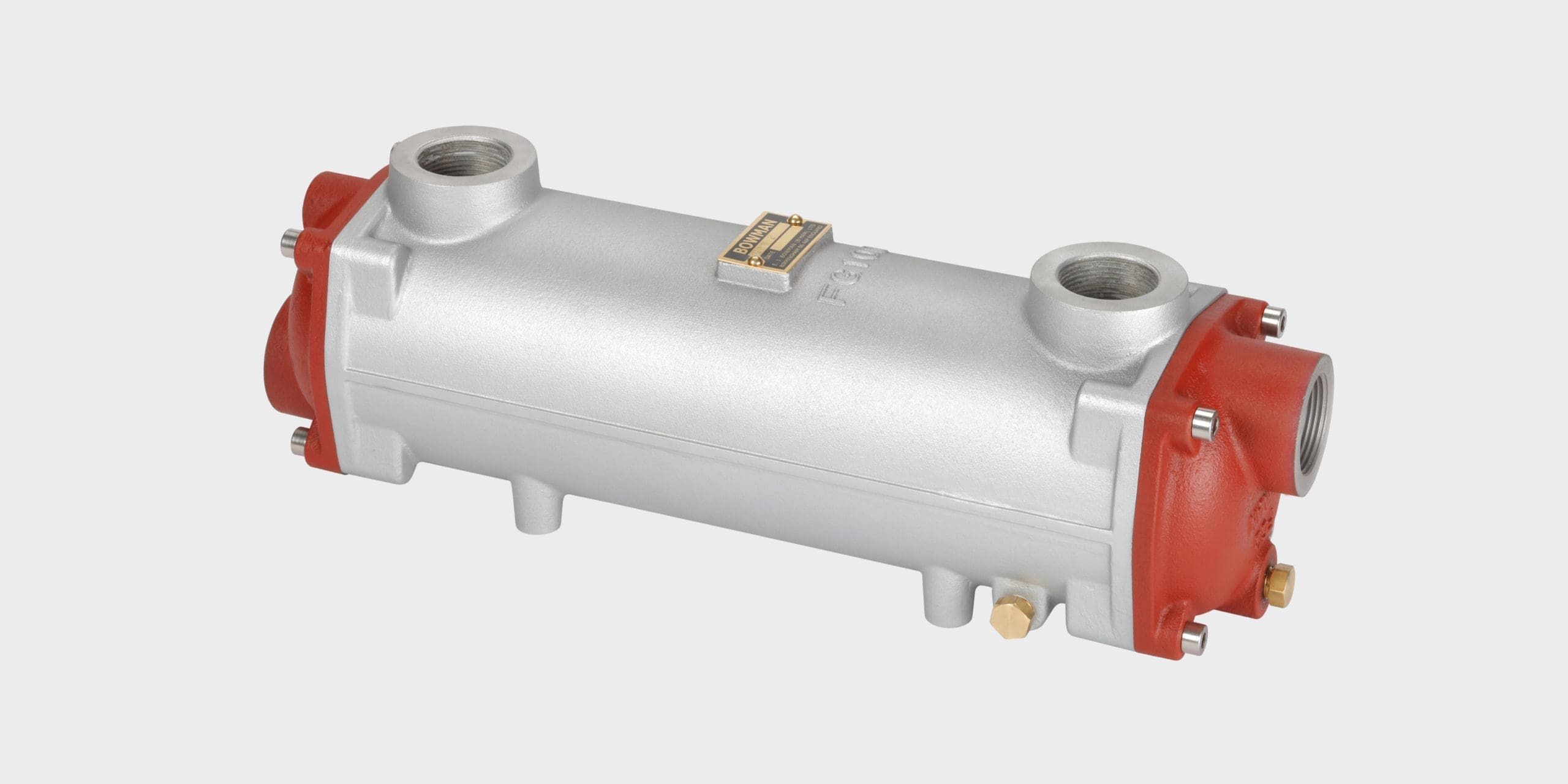

Bowman has a range of highly efficient oil coolers designed for marine and industrial engines and transmissions.

Efficient heat exchangers for cooling electric marine motors, hydrogen fuel cells, battery packs, chargers, AC-DC converters, DC-DC converters, inverters and associated equipment for electric and hybrid marine propulsion and charging systems.

Highly efficient heat transfer solutions for cooling a variety of applications where air and fluids need to be cooled by fluids.

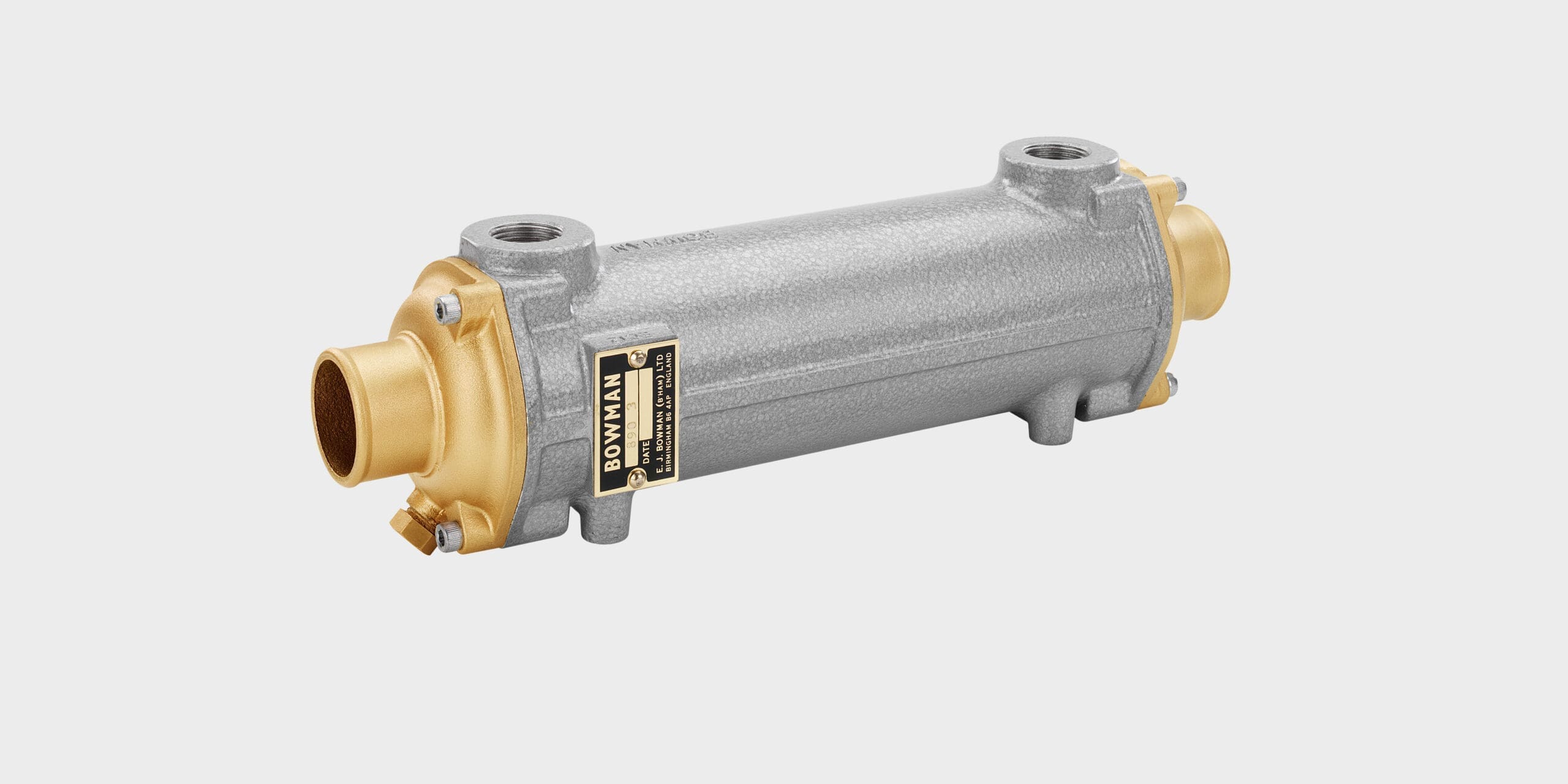

Many applications require stainless steel shell and tube heat exchangers and Bowman provide a standard range of units that are suitable for cooling or heating a variety of fluids.

Bowman swimming pool heat exchangers are renowned for reliability and efficiency. Whether heating your pool with a traditional boiler or a renewable energy source, Bowman is the obvious choice.

Premium quality heat exchangers and oil coolers for precise temperature control of engines under test cell development conditions.

Recovering waste heat energy from engine powered generating sets for biogas, diesel and natural gas applications up to 1 MW.

Efficient cooling for stationary / land-based engines where air cooling is either unavailable or inappropriate.

The reliable solution for cooling Electric & Hybrid Marine Propulsion Systems.

A comprehensive oil cooling solution for industrial hydraulic control systems, plus high temperature and mining applications.

A complete solution for cooling complex on-board hydraulic equipment, including thruster and stabiliser systems.

The complete cooling solution for marine engine propulsion, including the latest electric and hybrid systems.

An energy efficient solution for heating hot tubs and swim spas faster, significantly reducing heat-up time for guest change-over periods.

Quality heat exchangers for efficient swimming pool heating, using boiler or renewable energy heat sources.

Understand the importance of flow rates and how cooler selection can make the most of the coolant at your disposal…

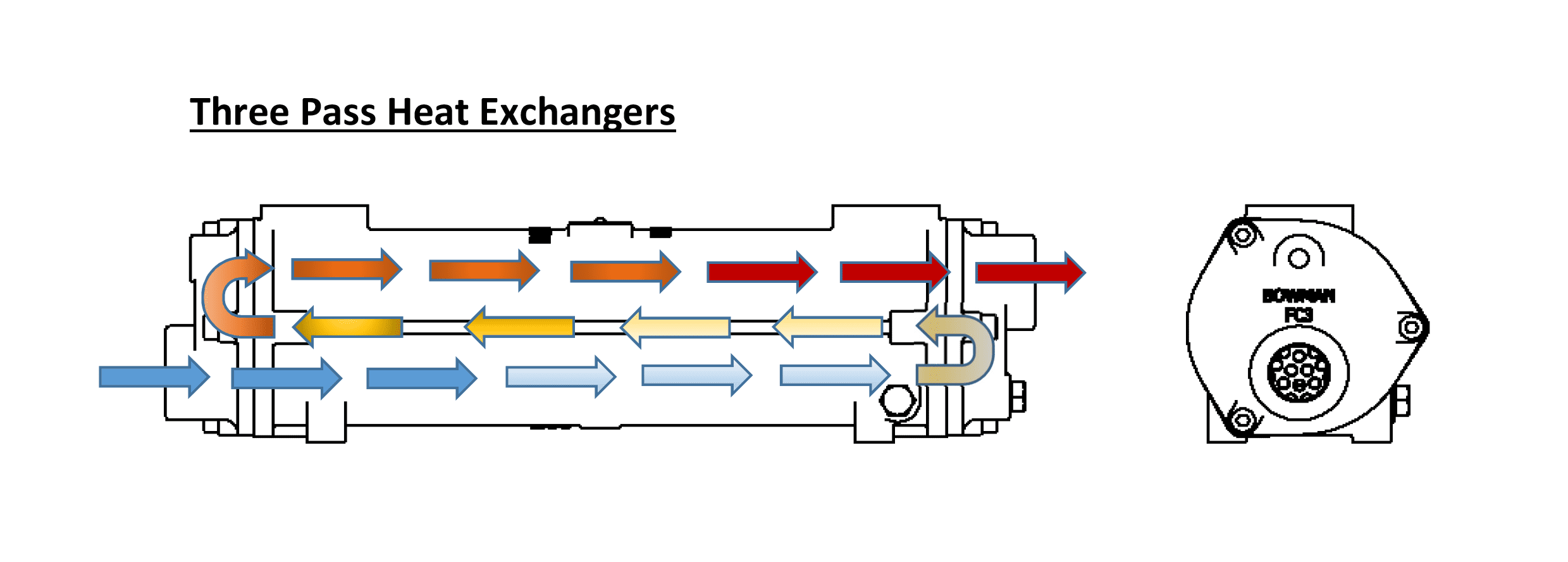

Getting the right specification for your heat exchanger can make a significant difference to the performance and life expectancy of the unit. Here we discuss the importance of single, double and triple pass cooling.

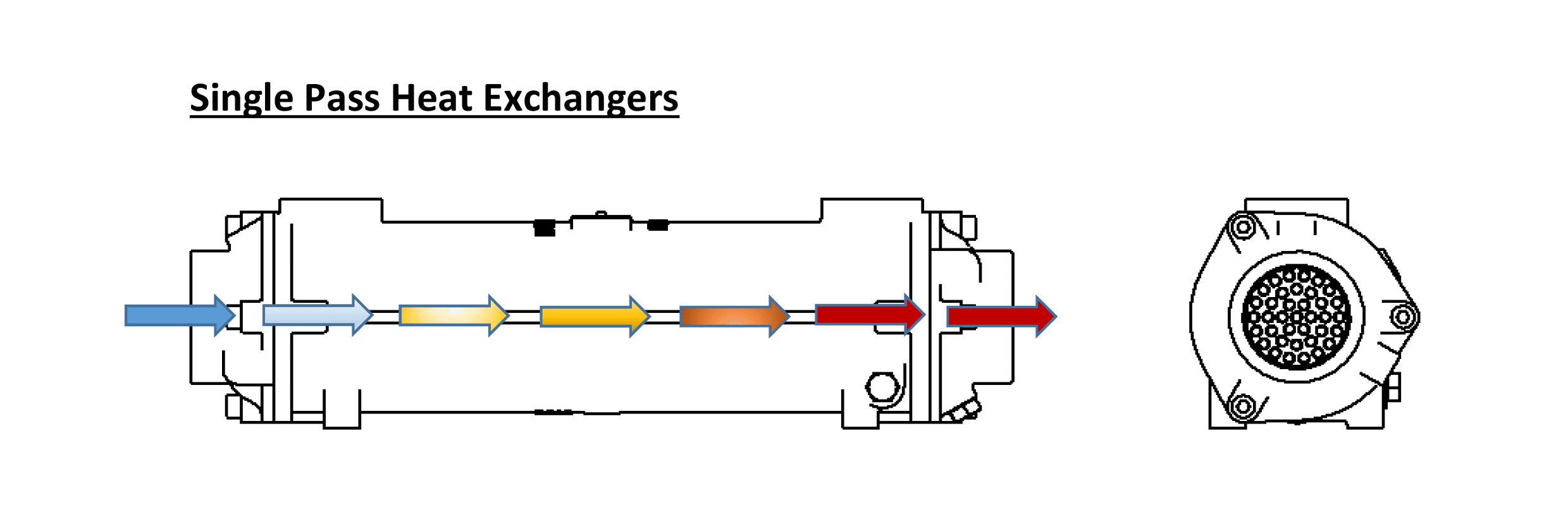

Every shell and tube heat exchanger carries a flow of cooling water through its central tube core. But depending on its design, the water may flow through the unit once, twice or three times, which is done to get the optimum cooling performance for the available volume of cooling water.

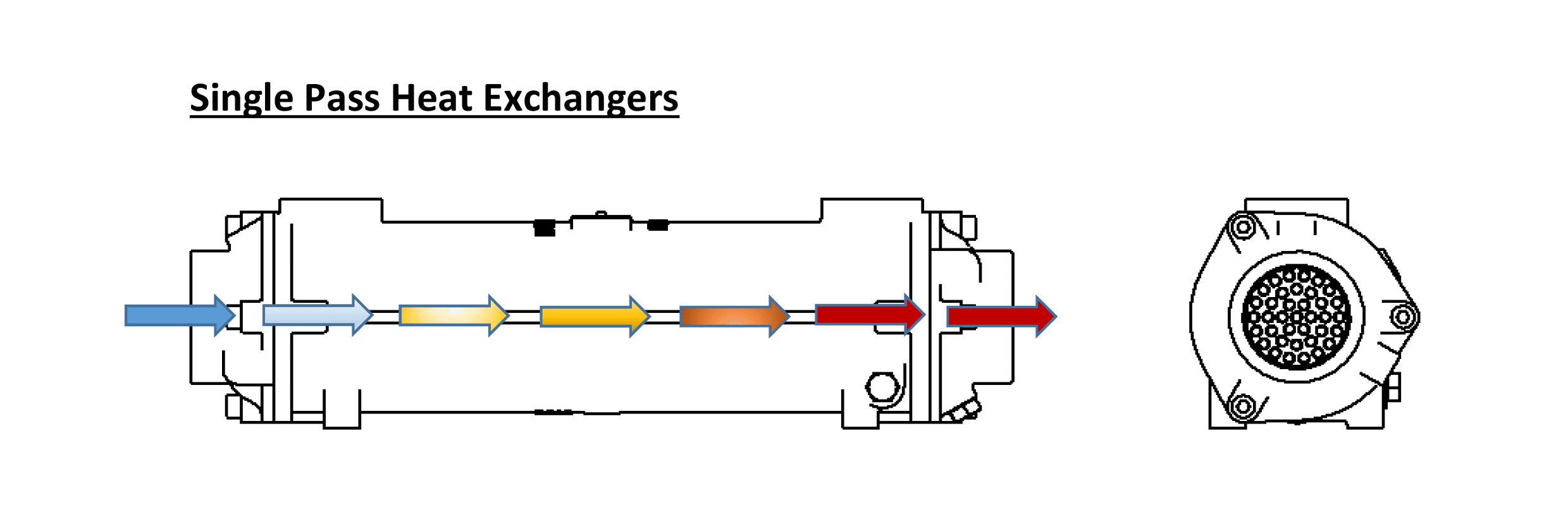

If the full volume of cooling water passes through all the tubes in the heat exchanger in a single flow, this format is known as single or 1-pass. The cooling water literally travels through the heat exchanger once, transferring heat from the ‘primary cooling circuit’ as it goes. For applications where there’s an abundance of cooling water, such as marine engine cooling, this arrangement is ideal.

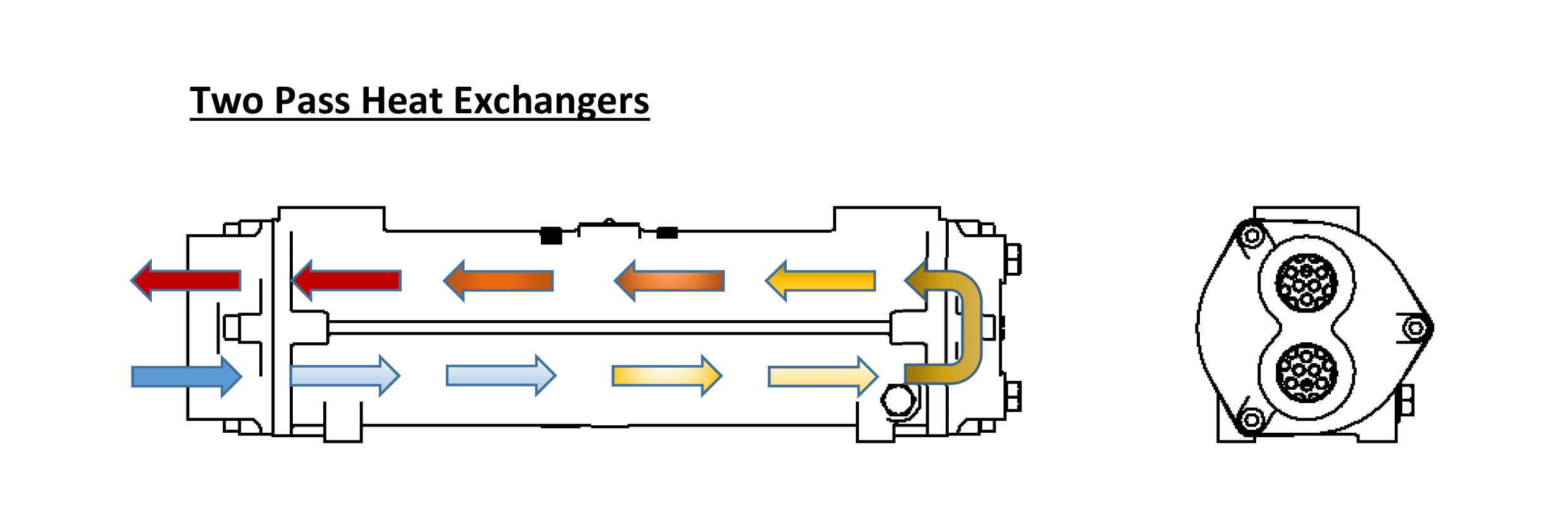

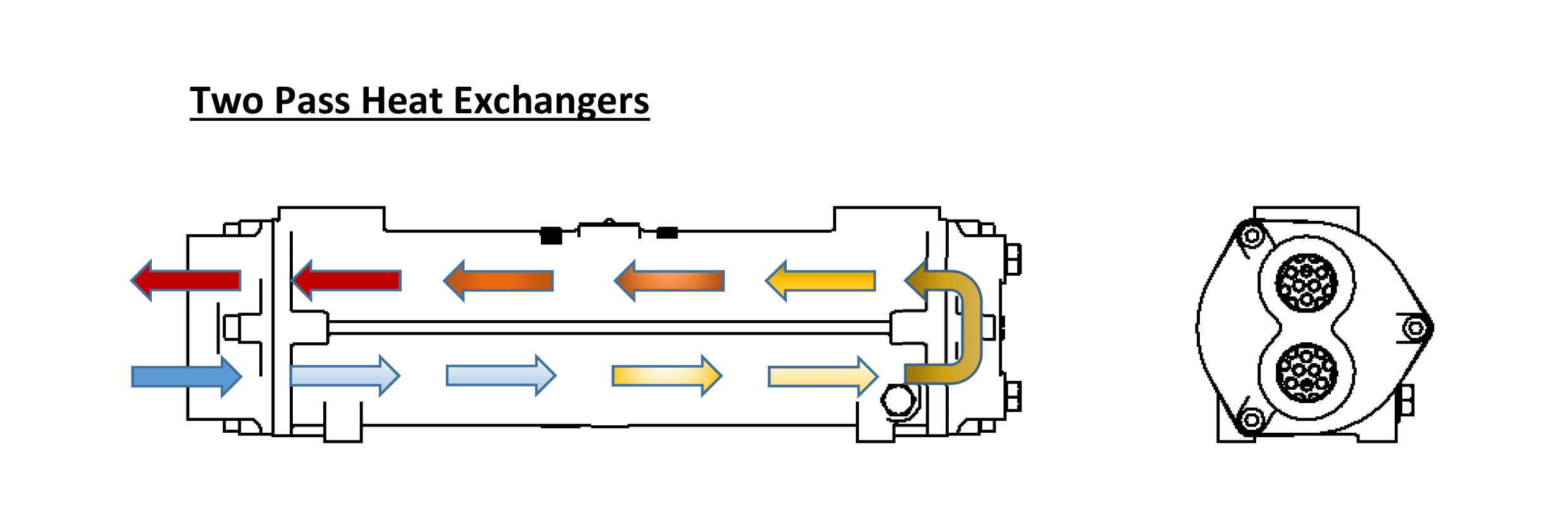

In some applications space is limited, so having the inlet and outlet on opposing sides of the heat exchanger can present packaging problems due to the pipework required. In such instances 2-pass heat exchangers are an ideal solution, as they feature inlet and outlet water connections on the same end cover, so the cooling water enters and leaves the heat exchanger in the same location. 2-pass heat exchangers are also capable of handling the higher water velocities found in marine cooling applications.

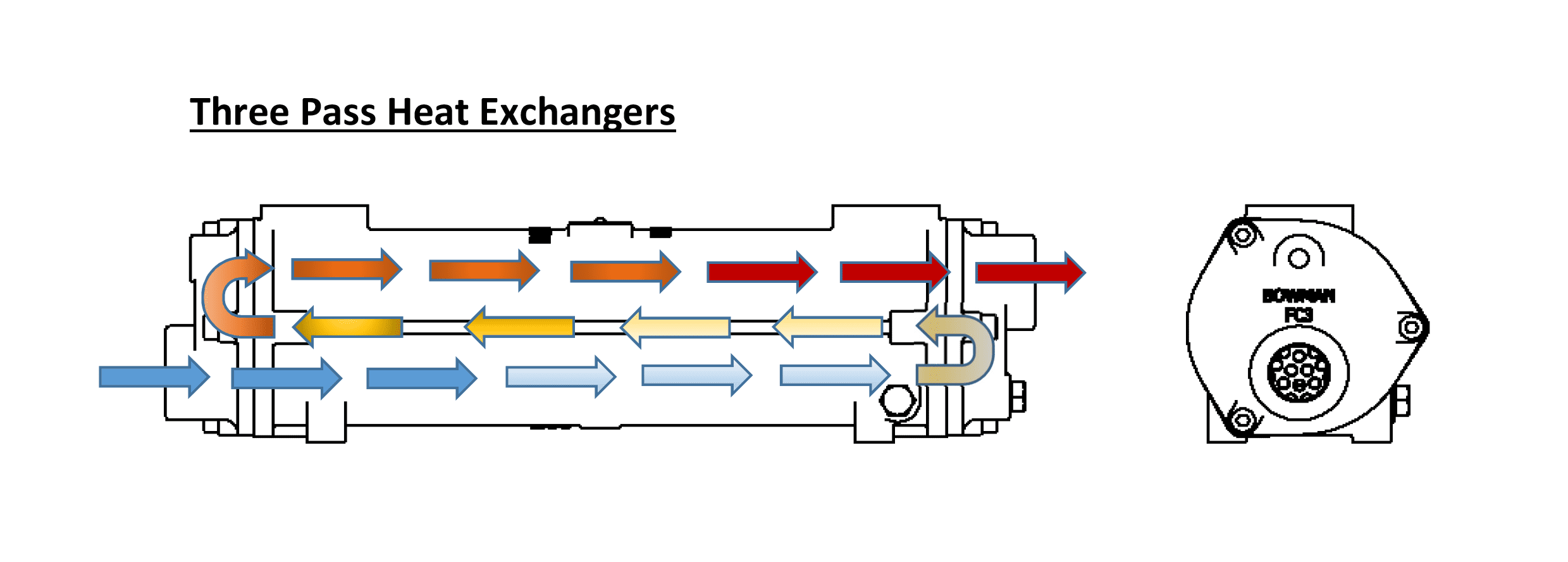

However, in many industrial or process cooling applications, the availability of cooling water may be limited. In these instances, triple or 3-pass cooling can provide the ideal solution. As the name suggests, the 3-pass arrangement uses specially designed end covers that effectively split the heat exchanger’s tube core into three separate sections. Cooling water enters the lower third of the heat exchanger and travels through to the opposing end cover, where it is sent back through the middle third of the tube core, after which it is passed back through the upper third of the unit before exiting the heat exchanger. Restricting the area to flow ensures the velocity of the available water is kept at a level that is most effective for the heat exchanger.

Flow rates and velocity of cooling water are vitally important to the performance and service life of a heat exchanger and in order to ensure the optimum flow rates are achieved, without encountering the problems associated with excessive water velocity, it is essential to select the most appropriate format for the heat exchanger and the application.

As the amount of cooling water increases, single or 2-pass heat exchangers become more suitable. Providing the velocity of the cooling water remains at the optimum level (see our technical literature or the article entitled ‘Terminal Velocity’), the heat transfer performance of the heat exchangers should improve with fewer passes through the unit.

Provided the flow of cooling water can be maintained at a suitable velocity, it is preferable that it flows through the heat exchanger as swiftly as possible in order to eliminate the possibility of the water heating up and becoming less effective at cooling the ‘primary cooling circuit’.

If you’re still unsure about the correct heat exchanger for your application, talk to Bowman’s technical sales team. They have a computer-aided selection programme designed to provide the optimum product for the job. Call +44 (0)121 359 5401 or email [email protected].

Understand the importance of flow rates and how cooler selection can make the most of the coolant at your disposal…

Getting the right specification for your heat exchanger can make a significant difference to the performance and life expectancy of the unit. Here we discuss the importance of single, double and triple pass cooling.

Every shell and tube heat exchanger carries a flow of cooling water through its central tube core. But depending on its design, the water may flow through the unit once, twice or three times, which is done to get the optimum cooling performance for the available volume of cooling water.

If the full volume of cooling water passes through all the tubes in the heat exchanger in a single flow, this format is known as single or 1-pass. The cooling water literally travels through the heat exchanger once, transferring heat from the ‘primary cooling circuit’ as it goes. For applications where there’s an abundance of cooling water, such as marine engine cooling, this arrangement is ideal.

In some applications space is limited, so having the inlet and outlet on opposing sides of the heat exchanger can present packaging problems due to the pipework required. In such instances 2-pass heat exchangers are an ideal solution, as they feature inlet and outlet water connections on the same end cover, so the cooling water enters and leaves the heat exchanger in the same location. 2-pass heat exchangers are also capable of handling the higher water velocities found in marine cooling applications.

However, in many industrial or process cooling applications, the availability of cooling water may be limited. In these instances, triple or 3-pass cooling can provide the ideal solution. As the name suggests, the 3-pass arrangement uses specially designed end covers that effectively split the heat exchanger’s tube core into three separate sections. Cooling water enters the lower third of the heat exchanger and travels through to the opposing end cover, where it is sent back through the middle third of the tube core, after which it is passed back through the upper third of the unit before exiting the heat exchanger. Restricting the area to flow ensures the velocity of the available water is kept at a level that is most effective for the heat exchanger.

Flow rates and velocity of cooling water are vitally important to the performance and service life of a heat exchanger and in order to ensure the optimum flow rates are achieved, without encountering the problems associated with excessive water velocity, it is essential to select the most appropriate format for the heat exchanger and the application.

As the amount of cooling water increases, single or 2-pass heat exchangers become more suitable. Providing the velocity of the cooling water remains at the optimum level (see our technical literature or the article entitled ‘Terminal Velocity’), the heat transfer performance of the heat exchangers should improve with fewer passes through the unit.

Provided the flow of cooling water can be maintained at a suitable velocity, it is preferable that it flows through the heat exchanger as swiftly as possible in order to eliminate the possibility of the water heating up and becoming less effective at cooling the ‘primary cooling circuit’.

If you’re still unsure about the correct heat exchanger for your application, talk to Bowman’s technical sales team. They have a computer-aided selection programme designed to provide the optimum product for the job. Call +44 (0)121 359 5401 or email [email protected].

Bowman and Rinnai provide the perfect heating solution for an Australian roof top pool – where winter temperatures can be surprisingly cool!

Six Bowman heat exchangers have been installed at the recently opened Gold’s Gym, Amman, Jordan, to heat two half Olympic-sized swimming pools.

How Bowman heat exchangers are helping this internationally renowned golf destination reduce energy costs and CO₂ emissions.

Bowman heat exchangers are playing an important role in the success of a flagship hotel on the Black Sea coast in Georgia.

Bowman and Rinnai provide the perfect heating solution for an Australian roof top pool – where winter temperatures can be surprisingly cool!

Six Bowman heat exchangers have been installed at the recently opened Gold’s Gym, Amman, Jordan, to heat two half Olympic-sized swimming pools.

How Bowman heat exchangers are helping this internationally renowned golf destination reduce energy costs and CO₂ emissions.

Bowman heat exchangers are playing an important role in the success of a flagship hotel on the Black Sea coast in Georgia.