Charge Air Coolers

Used to cool the hot, compressed air from the turbo before it reaches the engine, the intercoolers improve engine efficiency and reduce emissions for marine and land-based stationary engines.

Used to cool the hot, compressed air from the turbo before it reaches the engine, the intercoolers improve engine efficiency and reduce emissions for marine and land-based stationary engines.

Exhaust gas heat exchangers are designed to recover waste heat energy from the exhaust stream of reciprocating engine powered generating sets.

Bowman 'copper free' fuel coolers are compact, highly efficient heat exchangers suitable for fuel conditioning rigs in the automotive testing industry.

Engine coolant header tank heat exchangers for marine propulsion, gensets or stationary land-based engines.

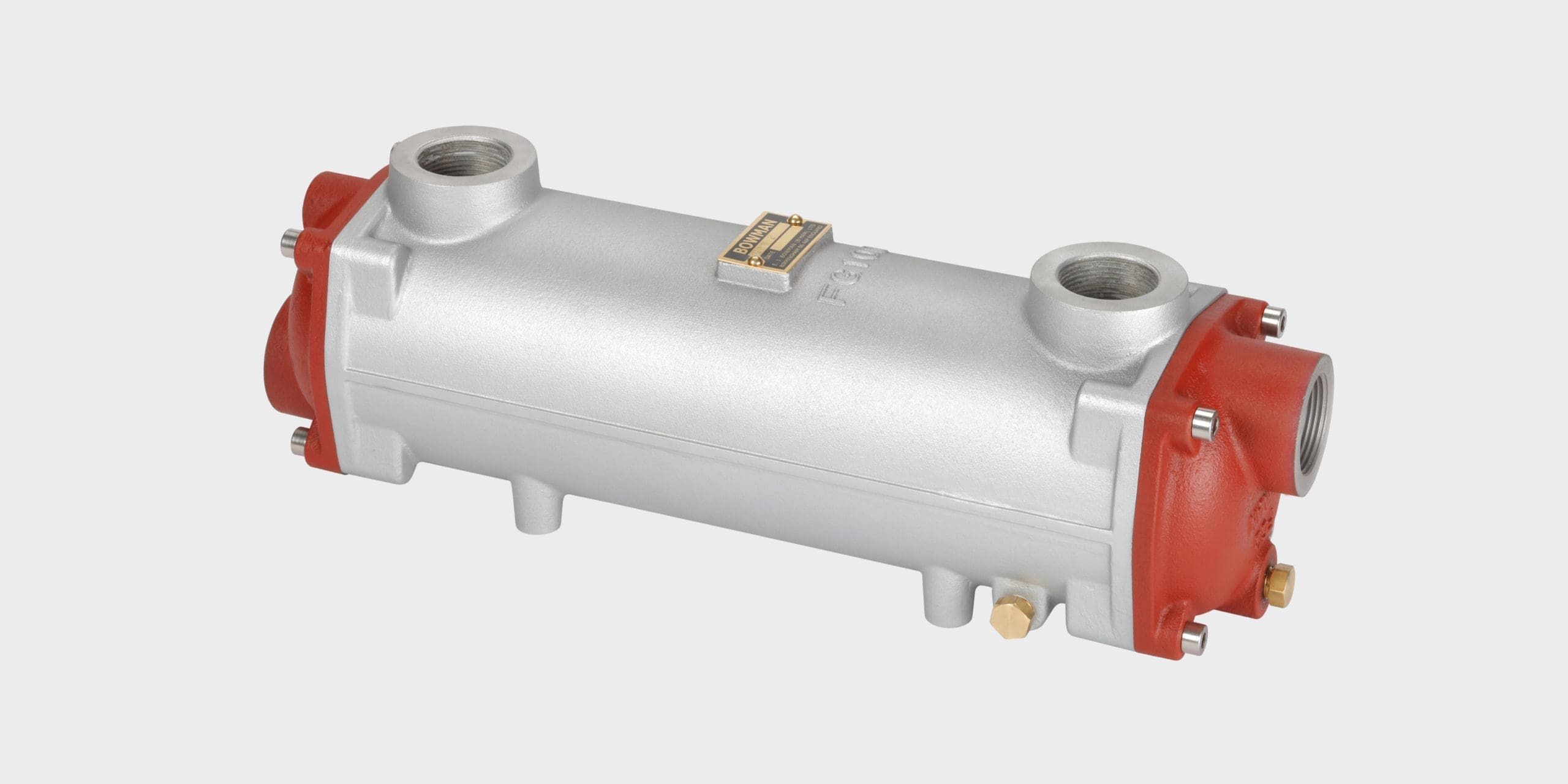

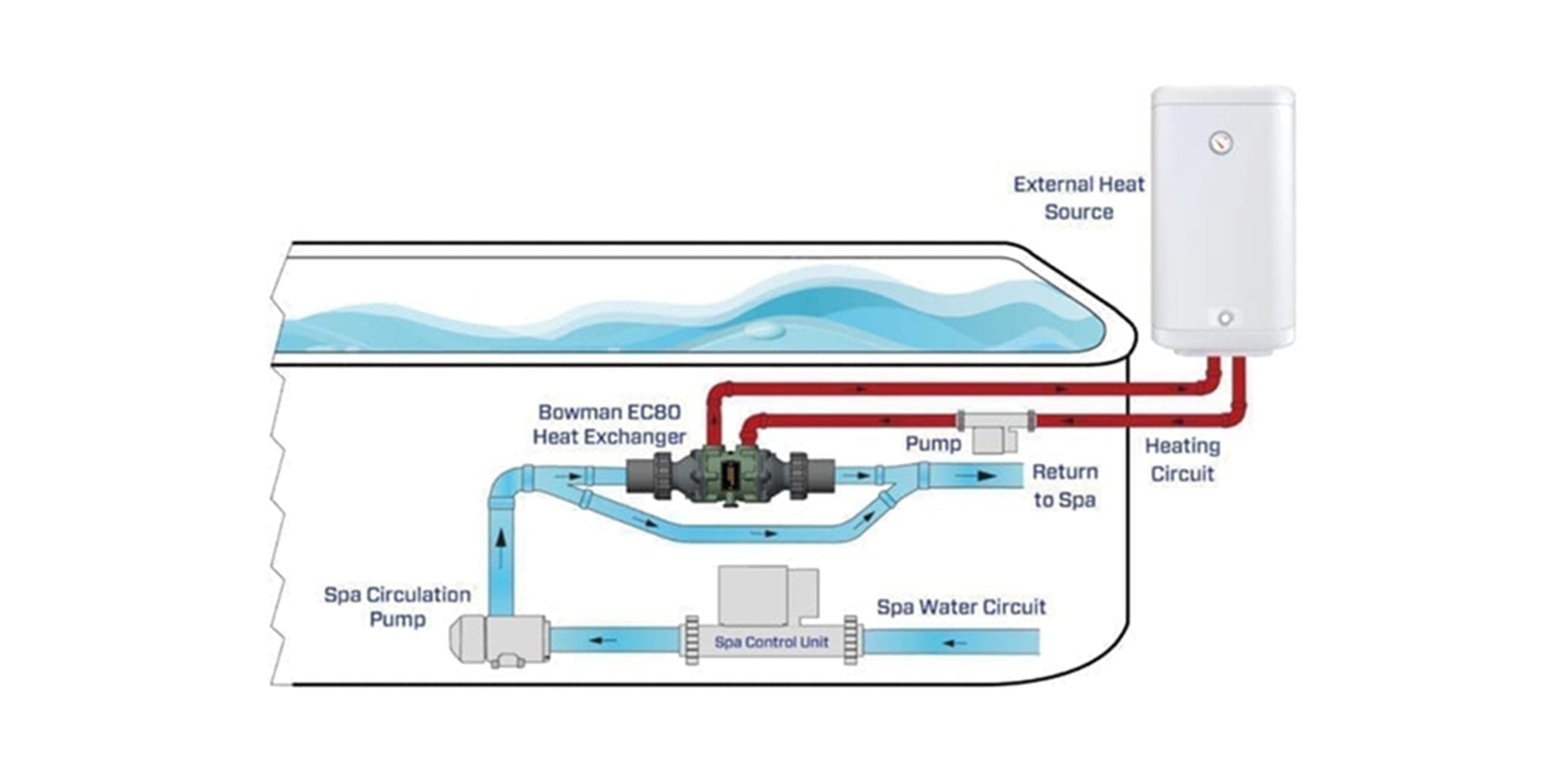

Bowman EC 80-5113-1T heat exchangers provide a new solution for heating spas and hot tubs in just a fraction of the time taken by traditional electric heaters.

Highly efficient heat transfer solutions for cooling marine, land-based and underground hydraulic systems.

Bowman inline plate heat exchangers are a compact, economical solution for high efficiency heat transfer.

Bespoke cooling solutions for a range of popular marine engines from major OEMs, including coolant heat exchangers, charge air coolers, plus combined heat exchangers and exhaust manifolds, suitable for cooling marine engines up to 1 MW.

Bowman has a range of highly efficient oil coolers designed for marine and industrial engines and transmissions.

Efficient heat exchangers for cooling electric marine motors, hydrogen fuel cells, battery packs, chargers, AC-DC converters, DC-DC converters, inverters and associated equipment for electric and hybrid marine propulsion and charging systems.

Highly efficient heat transfer solutions for cooling a variety of applications where air and fluids need to be cooled by fluids.

Many applications require stainless steel shell and tube heat exchangers and Bowman provide a standard range of units that are suitable for cooling or heating a variety of fluids.

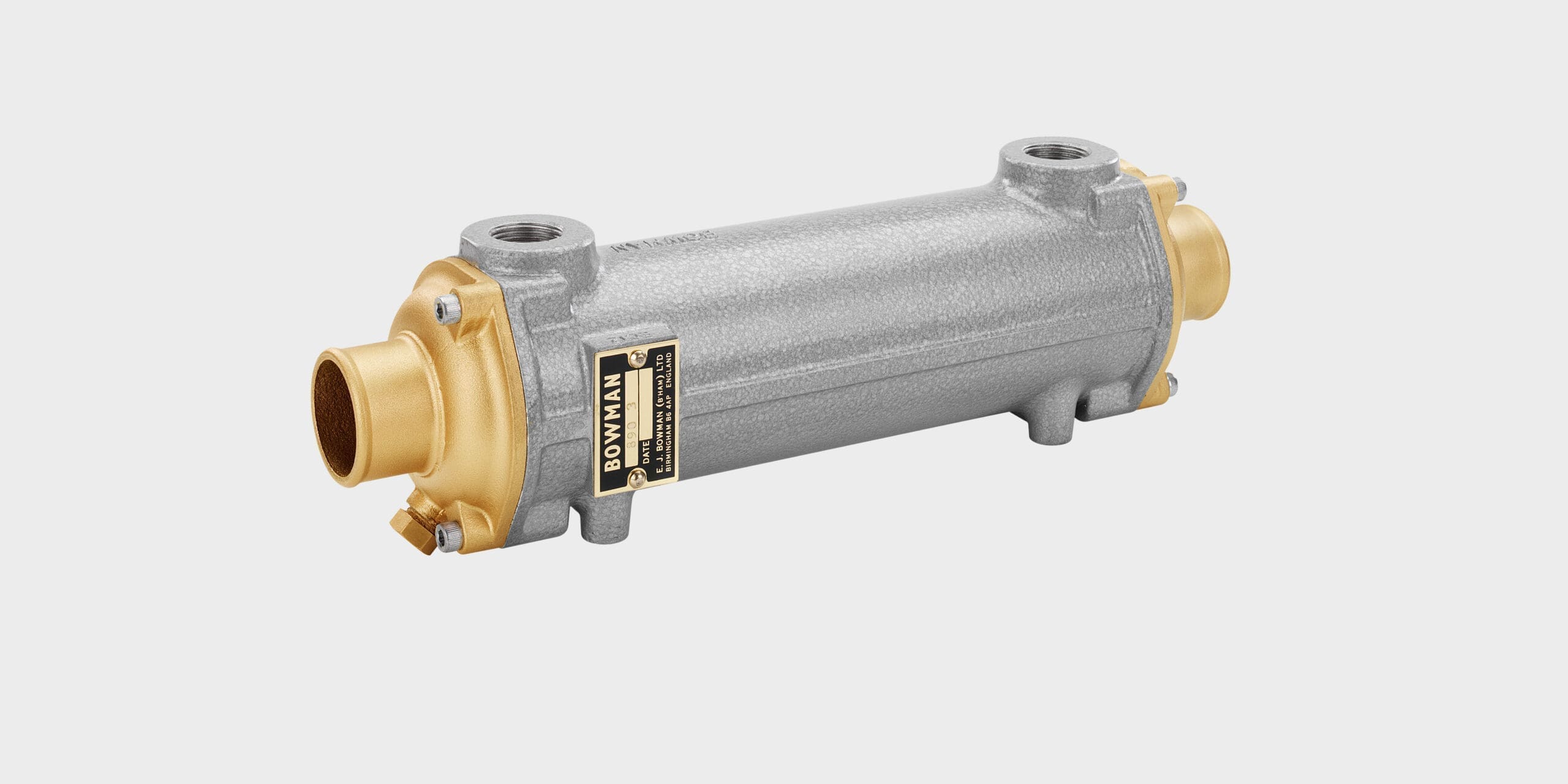

Bowman swimming pool heat exchangers are renowned for reliability and efficiency. Whether heating your pool with a traditional boiler or a renewable energy source, Bowman is the obvious choice.

Premium quality heat exchangers and oil coolers for precise temperature control of engines under test cell development conditions.

Recovering waste heat energy from engine powered generating sets for biogas, diesel and natural gas applications up to 1 MW.

Efficient cooling for stationary / land-based engines where air cooling is either unavailable or inappropriate.

The reliable solution for cooling Electric & Hybrid Marine Propulsion Systems.

A comprehensive oil cooling solution for industrial hydraulic control systems, plus high temperature and mining applications.

A complete solution for cooling complex on-board hydraulic equipment, including thruster and stabiliser systems.

The complete cooling solution for marine engine propulsion, including the latest electric and hybrid systems.

An energy efficient solution for heating hot tubs and swim spas faster, significantly reducing heat-up time for guest change-over periods.

Quality heat exchangers for efficient swimming pool heating, using boiler or renewable energy heat sources.

Saves space. Simplifies installation

Provided quickly by our technical experts

UK manufactured, robust and reliable

Suitable for engines up to 1 MW

Extensive stockholding for fast response

Fluid enters the outer ‘shell’ of the unit and travels over a series of specially designed baffles, transferring energy from the exhaust gases which travel through the tubes of the heat exchanger.

Fully welded construction using 316 stainless steel ensures maximum reliability and durability of the unit, when handling extreme exhaust gas temperatures.

The automated tube end welding process of the tube core ensures ultra-high quality, whilst every unit is 100% inspected for structural integrity.

Bowman exhaust gas heat exchangers are renowned for their high quality, which translates into long-life durability, even where more aggressive fuels, such as biogas, are used.

In addition to offering a more compact packaging solution, right angle end covers often reduce system pipework requirements and enable the tubes to be cleaned, without disturbing the pipework.

Bowman exhaust gas heat exchangers are fitted with a pressure relief valve which automatically activates, should the pressure exceed 4 bar, to prevent excess pressure build up.

The following information offers a general guide to the performance and dimensions of our standard range of exhaust gas heat exchangers. For more detailed information on additional configurations and specific applications, please download the product brochure. Computer aided selection software (CAS) can be used to accurately select the correct heat exchanger specifically for your application.

Please contact us or your nearest stockist with the following information to receive a CAS selection:

Note – Water pressure must not exceed 4 bar at 110 °C and gas inlet pressure should be below 0.5 bar at 700 °C.

The figures given in the table are based on a natural gas engine using a gas inlet temperature of 600 °C and water inlet temperature of 80 °C and the dimensions in the table below refer to standard units fitted with straight end covers – for alternative configurations please download the brochure or contact us for further information.

| Model | Typical Engine Power (kW) | Mass Flow (kg/min) | Pressure Drop (kPa) | Gas Outlet (°C) | Heat Recovery | Dim A (mm) | Dim B (mm) | Dim C (mm) | Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|

| 2-25 | 16 | 1.2 | 1.6 | 210 | 9.5 | 750 | 550 | 60.3 | 10 |

| 2-32 | 16 | 1.2 | 1.8 | 170 | 11.5 | 928 | 728 | 60.3 | 12 |

| 3-32 | 32 | 2.4 | 1.2 | 198 | 19 | 960 | 718 | 88.9 | 18 |

| 3-40 | 32 | 2.4 | 1.3 | 163 | 21 | 1162 | 920 | 88.9 | 20 |

| 3-60 | 32 | 2.4 | 1.6 | 116 | 23 | 1670 | 1428 | 88.9 | 27 |

| 4-32 | 60 | 4.5 | 1.0 | 199 | 36 | 990 | 698 | 114.3 | 25 |

| 4-40 | 60 | 4.5 | 1.2 | 164 | 39 | 1192 | 900 | 114.3 | 29 |

| 4-60 | 60 | 4.5 | 1.4 | 116 | 43 | 1700 | 1408 | 114.3 | 40 |

| 5-32 | 90 | 6.7 | 1.0 | 195 | 55 | 1030 | 688 | 141.3 | 36 |

| 5-40 | 90 | 6.7 | 1.2 | 161 | 59 | 1232 | 890 | 141.3 | 39 |

| 5-60 | 90 | 6.7 | 1.4 | 115 | 65 | 1740 | 1398 | 141.3 | 51 |

| 6-32 | 140 | 10.5 | 1.0 | 197 | 85 | 1080 | 668 | 168.3 | 48 |

| 6-40 | 140 | 10.5 | 1.2 | 163 | 92 | 1282 | 870 | 168.3 | 55 |

| 6-60 | 140 | 10.5 | 1.4 | 117 | 101 | 1790 | 1378 | 168.3 | 72 |

| Model: 2-25 | Typical Engine Power (kW) 16 | Mass Flow (kg/min) 1.2 | Pressure Drop (kPa) 1.6 | Gas Outlet (°C) 210 | Heat Recovery 9.5 | Dim A (mm) 750 | Dim B (mm) 550 | Dim C (mm) 60.3 | Weight (kg) 10 |

| Model: 2-32 | Typical Engine Power (kW) 16 | Mass Flow (kg/min) 1.2 | Pressure Drop (kPa) 1.8 | Gas Outlet (°C) 170 | Heat Recovery 11.5 | Dim A (mm) 928 | Dim B (mm) 728 | Dim C (mm) 60.3 | Weight (kg) 12 |

| Model: 3-32 | Typical Engine Power (kW) 32 | Mass Flow (kg/min) 2.4 | Pressure Drop (kPa) 1.2 | Gas Outlet (°C) 198 | Heat Recovery 19 | Dim A (mm) 960 | Dim B (mm) 718 | Dim C (mm) 88.9 | Weight (kg) 18 |

| Model: 3-40 | Typical Engine Power (kW) 32 | Mass Flow (kg/min) 2.4 | Pressure Drop (kPa) 1.3 | Gas Outlet (°C) 163 | Heat Recovery 21 | Dim A (mm) 1162 | Dim B (mm) 920 | Dim C (mm) 88.9 | Weight (kg) 20 |

| Model: 3-60 | Typical Engine Power (kW) 32 | Mass Flow (kg/min) 2.4 | Pressure Drop (kPa) 1.6 | Gas Outlet (°C) 116 | Heat Recovery 23 | Dim A (mm) 1670 | Dim B (mm) 1428 | Dim C (mm) 88.9 | Weight (kg) 27 |

| Model: 4-32 | Typical Engine Power (kW) 60 | Mass Flow (kg/min) 4.5 | Pressure Drop (kPa) 1.0 | Gas Outlet (°C) 199 | Heat Recovery 36 | Dim A (mm) 990 | Dim B (mm) 698 | Dim C (mm) 114.3 | Weight (kg) 25 |

| Model: 4-40 | Typical Engine Power (kW) 60 | Mass Flow (kg/min) 4.5 | Pressure Drop (kPa) 1.2 | Gas Outlet (°C) 164 | Heat Recovery 39 | Dim A (mm) 1192 | Dim B (mm) 900 | Dim C (mm) 114.3 | Weight (kg) 29 |

| Model: 4-60 | Typical Engine Power (kW) 60 | Mass Flow (kg/min) 4.5 | Pressure Drop (kPa) 1.4 | Gas Outlet (°C) 116 | Heat Recovery 43 | Dim A (mm) 1700 | Dim B (mm) 1408 | Dim C (mm) 114.3 | Weight (kg) 40 |

| Model: 5-32 | Typical Engine Power (kW) 90 | Mass Flow (kg/min) 6.7 | Pressure Drop (kPa) 1.0 | Gas Outlet (°C) 195 | Heat Recovery 55 | Dim A (mm) 1030 | Dim B (mm) 688 | Dim C (mm) 141.3 | Weight (kg) 36 |

| Model: 5-40 | Typical Engine Power (kW) 90 | Mass Flow (kg/min) 6.7 | Pressure Drop (kPa) 1.2 | Gas Outlet (°C) 161 | Heat Recovery 59 | Dim A (mm) 1232 | Dim B (mm) 890 | Dim C (mm) 141.3 | Weight (kg) 39 |

| Model: 5-60 | Typical Engine Power (kW) 90 | Mass Flow (kg/min) 6.7 | Pressure Drop (kPa) 1.4 | Gas Outlet (°C) 115 | Heat Recovery 65 | Dim A (mm) 1740 | Dim B (mm) 1398 | Dim C (mm) 141.3 | Weight (kg) 51 |

| Model: 6-32 | Typical Engine Power (kW) 140 | Mass Flow (kg/min) 10.5 | Pressure Drop (kPa) 1.0 | Gas Outlet (°C) 197 | Heat Recovery 85 | Dim A (mm) 1080 | Dim B (mm) 668 | Dim C (mm) 168.3 | Weight (kg) 48 |

| Model: 6-40 | Typical Engine Power (kW) 140 | Mass Flow (kg/min) 10.5 | Pressure Drop (kPa) 1.2 | Gas Outlet (°C) 163 | Heat Recovery 92 | Dim A (mm) 1282 | Dim B (mm) 870 | Dim C (mm) 168.3 | Weight (kg) 55 |

| Model: 6-60 | Typical Engine Power (kW) 140 | Mass Flow (kg/min) 10.5 | Pressure Drop (kPa) 1.4 | Gas Outlet (°C) 117 | Heat Recovery 101 | Dim A (mm) 1790 | Dim B (mm) 1378 | Dim C (mm) 168.3 | Weight (kg) 72 |

The figures given in the table are based on a natural gas engine using a gas inlet temperature of 600 °C and water inlet temperature of 80 °C and the dimensions in the table below refer to standard units fitted with straight end covers – for alternative configurations please download the brochure or contact us for further information.

| Model | Typical Power (kW) | Mass Flow (kg/min) | Pressure Drop (kPa) | Gas Outlet (°C) | Heat Recovery (kW) | Dim A (mm) | Dim B (mm) | Dim C (mm) | Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|

| 8-32 | 250 | 18.7 | 1.0 | 199 | 151 | 1150 | 648 | 219.0 | 89 |

| 8-40 | 250 | 18.7 | 1.2 | 164 | 163 | 1352 | 850 | 219.0 | 98 |

| 8-60 | 250 | 18.7 | 1.4 | 117 | 180 | 1860 | 1358 | 219.0 | 125 |

| 10-32 | 400 | 30.0 | 1.1 | 200 | 241 | 1230 | 608 | 273.0 | 132 |

| 10-40 | 400 | 30.0 | 1.2 | 164 | 262 | 1432 | 810 | 273.0 | 146 |

| 10-60 | 400 | 30.0 | 1.4 | 116 | 289 | 1940 | 1318 | 273.0 | 185 |

| 12-32 | 600 | 45.0 | 1.1 | 199 | 362 | 1330 | 538 | 324.0 | 190 |

| 12-40 | 600 | 45.0 | 1.2 | 164 | 392 | 1532 | 740 | 324.0 | 208 |

| 12-60 | 600 | 45.0 | 1.5 | 117 | 432 | 2040 | 1248 | 324.0 | 268 |

| 15-32 | 950 | 70.0 | 1.0 | 200 | 563 | 1468 | 538 | 406.4 | 288 |

| 15-40 | 950 | 70.0 | 1.1 | 165 | 610 | 1670 | 740 | 406.4 | 319 |

| 15-60 | 950 | 70.0 | 1.4 | 116 | 673 | 2180 | 1248 | 406.4 | 404 |

| Model: 8-32 | Typical Power (kW) 250 | Mass Flow (kg/min) 18.7 | Pressure Drop (kPa) 1.0 | Gas Outlet (°C) 199 | Heat Recovery (kW) 151 | Dim A (mm) 1150 | Dim B (mm) 648 | Dim C (mm) 219.0 | Weight (kg) 89 |

| Model: 8-40 | Typical Power (kW) 250 | Mass Flow (kg/min) 18.7 | Pressure Drop (kPa) 1.2 | Gas Outlet (°C) 164 | Heat Recovery (kW) 163 | Dim A (mm) 1352 | Dim B (mm) 850 | Dim C (mm) 219.0 | Weight (kg) 98 |

| Model: 8-60 | Typical Power (kW) 250 | Mass Flow (kg/min) 18.7 | Pressure Drop (kPa) 1.4 | Gas Outlet (°C) 117 | Heat Recovery (kW) 180 | Dim A (mm) 1860 | Dim B (mm) 1358 | Dim C (mm) 219.0 | Weight (kg) 125 |

| Model: 10-32 | Typical Power (kW) 400 | Mass Flow (kg/min) 30.0 | Pressure Drop (kPa) 1.1 | Gas Outlet (°C) 200 | Heat Recovery (kW) 241 | Dim A (mm) 1230 | Dim B (mm) 608 | Dim C (mm) 273.0 | Weight (kg) 132 |

| Model: 10-40 | Typical Power (kW) 400 | Mass Flow (kg/min) 30.0 | Pressure Drop (kPa) 1.2 | Gas Outlet (°C) 164 | Heat Recovery (kW) 262 | Dim A (mm) 1432 | Dim B (mm) 810 | Dim C (mm) 273.0 | Weight (kg) 146 |

| Model: 10-60 | Typical Power (kW) 400 | Mass Flow (kg/min) 30.0 | Pressure Drop (kPa) 1.4 | Gas Outlet (°C) 116 | Heat Recovery (kW) 289 | Dim A (mm) 1940 | Dim B (mm) 1318 | Dim C (mm) 273.0 | Weight (kg) 185 |

| Model: 12-32 | Typical Power (kW) 600 | Mass Flow (kg/min) 45.0 | Pressure Drop (kPa) 1.1 | Gas Outlet (°C) 199 | Heat Recovery (kW) 362 | Dim A (mm) 1330 | Dim B (mm) 538 | Dim C (mm) 324.0 | Weight (kg) 190 |

| Model: 12-40 | Typical Power (kW) 600 | Mass Flow (kg/min) 45.0 | Pressure Drop (kPa) 1.2 | Gas Outlet (°C) 164 | Heat Recovery (kW) 392 | Dim A (mm) 1532 | Dim B (mm) 740 | Dim C (mm) 324.0 | Weight (kg) 208 |

| Model: 12-60 | Typical Power (kW) 600 | Mass Flow (kg/min) 45.0 | Pressure Drop (kPa) 1.5 | Gas Outlet (°C) 117 | Heat Recovery (kW) 432 | Dim A (mm) 2040 | Dim B (mm) 1248 | Dim C (mm) 324.0 | Weight (kg) 268 |

| Model: 15-32 | Typical Power (kW) 950 | Mass Flow (kg/min) 70.0 | Pressure Drop (kPa) 1.0 | Gas Outlet (°C) 200 | Heat Recovery (kW) 563 | Dim A (mm) 1468 | Dim B (mm) 538 | Dim C (mm) 406.4 | Weight (kg) 288 |

| Model: 15-40 | Typical Power (kW) 950 | Mass Flow (kg/min) 70.0 | Pressure Drop (kPa) 1.1 | Gas Outlet (°C) 165 | Heat Recovery (kW) 610 | Dim A (mm) 1670 | Dim B (mm) 740 | Dim C (mm) 406.4 | Weight (kg) 319 |

| Model: 15-60 | Typical Power (kW) 950 | Mass Flow (kg/min) 70.0 | Pressure Drop (kPa) 1.4 | Gas Outlet (°C) 116 | Heat Recovery (kW) 673 | Dim A (mm) 2180 | Dim B (mm) 1248 | Dim C (mm) 406.4 | Weight (kg) 404 |

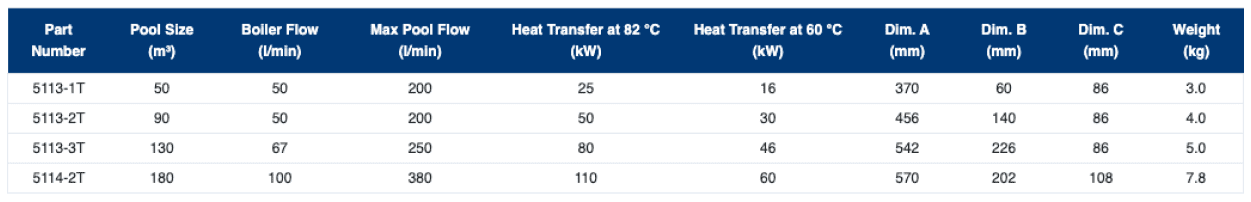

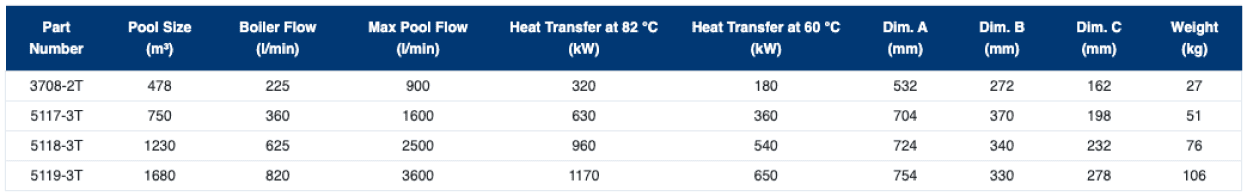

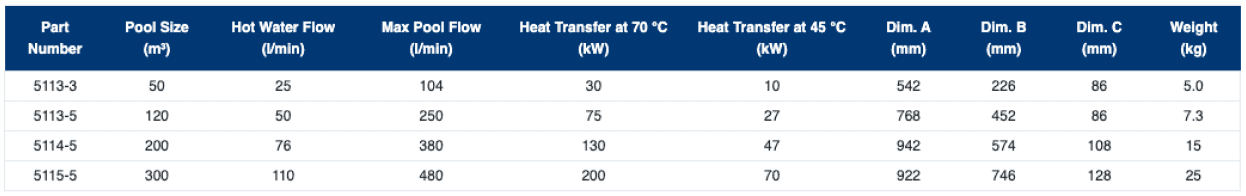

The table below enables the selection of the most appropriate heat exchanger for your swimming pool or spa. The information shows the amount of heat that can be transferred from either boiler or renewable energy sources, together with the basic dimensions of each unit. Typical pool sizes are also shown as a guide. For further information please download the product brochure, contact us or your nearest stockist.

Note – Ratings and weight are specifically relevant to the titanium versions of each heat exchanger. Download the brochure for more detailed information.

Note – Ratings and weight are specifically relevant to the titanium versions of each heat exchanger. Download the brochure for more detailed information.

Note – Ratings and weight are specifically relevant to the titanium versions of each heat exchanger. Download the brochure for more detailed information.

Note – Weight provided are for the titanium versions.

For spas, hot tubs and small private pools

For mid sized private and commercial pools

For large commercial and public pools

For more information on JK190-5118-3 and PK190-5119-3 please contact Bowman.

For transferring heat from solar panels and heat pumps

For spas, hot tubs and small private pools

For mid sized private and commercial pools

For large commercial and public pools

For more information on JK190-5110-3 and PK190-5111-3 please contact Bowman.

For transferring heat from solar panels and heat pumps

No download content found.

Technical sales brochure includes product information, ratings charts, drawings and dimensions for the standard product range.

Technical sales brochure includes product information, ratings charts, drawings and dimensions for the standard product range.

Technical sales brochure includes product information, ratings charts, drawings and dimensions for the standard product range.

Technical sales brochure includes product information, ratings charts, drawings and dimensions for the standard product range.

Technical sales brochure includes product information, ratings charts, drawings and dimensions for the standard product range.

Technical sales brochure includes product information, ratings charts, drawings and dimensions for the standard product range.

Technical sales brochure includes product information, ratings charts, drawings and dimensions for the standard product range.

Technical sales brochure includes product information, ratings charts, drawings and dimensions for the standard product range.

Technical sales brochure includes product information, ratings charts, drawings and dimensions for the standard product range.

Technical sales brochure includes product information, ratings charts, drawings and dimensions for the standard product range.

Technical sales brochure includes product information, ratings charts, drawings and dimensions for the standard product range.

Technical sales brochure includes product information, ratings charts, drawings and dimensions for the standard product range.

Technical sales brochure includes product information, ratings charts, drawings and dimensions for the standard product range.

Technical sales brochure includes product information, ratings charts, drawings and dimensions for the standard product range.

A heat exchanger is a device for transferring heat energy from a liquid or gas, to another liquid or gas without the two ever coming into contact with each other. A typical shell and tube heat exchanger will contain a tube bundle inside an outer shell, or body. Cold water flows through these tubes, whilst hot water, or gas flows around the outside of the tubes, enabling the heat from the hot water or gas to be transferred to the colder water inside the tubes.

A good example of how the process works are swimming pools, where most are heated via a boiler, using Gas, LPG or Biomass as the energy source. In theory, the most efficient way to heat the pool would be to circulate the pool water directly through the boiler. But were this to happen, the chemicals used in the pool water to keep it safe for use, would quickly corrode and damage vital parts inside the boiler, leading to premature failure and a costly replacement.

However, by using a heat exchanger to act as an ‘interface’ between the boiler water circuit and the pool water circuit, the boiler is protected from damage and the pool water is quickly heated up to the required temperature; the pool water passing through the central ‘tube core’, whilst the hot boiler water circulates around the outside of the tubes, transferring heat energy to the pool water.

More examples of applications where Bowman heat exchangers are used.

In a shell and tube heat exchanger, coolant usually flows through the central ‘tube core’ to cool hot oil, water or air, which passes over and around the tubes. The direction in which the two fluids travel through the heat exchanger can be either ‘parallel flow’ or ‘counterflow’.

Parallel flow is where the fluid to be cooled, flows through the heat exchanger in the same direction as the cooling medium. Whilst this arrangement will provide cooling, it has limitations and can also create thermal stress within the heat exchanger, as one half of the unit will be appreciably warmer than the other.

In counterflow cooling, the incoming cooling medium absorbs more heat as the ‘hot’ fluid travels in the opposite direction. The cooling medium heats up as it travels through the heat exchanger, but as colder water enters the heat exchanger it absorbs more heat, reducing the temperature much lower than could be achieved with parallel flow.

The mean temperature difference between the cooling medium and the fluid being cooled is also more uniform along the length of the heat exchanger, reducing thermal stress.

Depending on flow rate and temperature, the heat transfer performance could be up to 15% more efficient with counterflow, possibly enabling a smaller heat exchanger to be used, saving space and money!

More information on the benefits of counterflow.

A CHP (Combined Heat and Power) unit generates electrical power and heat from a single energy source.

There are three primary components within a CHP unit, starting with the Prime Mover, (usually a reciprocating engine) that creates the motive power to drive the Electrical Generator. The final component is the Heat Recovery system, which comprises of single or multiple heat exchangers installed on key areas of the engine, to recover waste heat produced as a bye-product.

In an engine powered CHP unit, around 30% of the fuel used gets converted to electrical power. At the same time, around 50% of the fuel energy gets converted to heat. Without heat recovery, this valuable and highly usable energy stream would be lost to the atmosphere, wasting around half the cost of all fuel used to power the generator. By recovering this heat energy, the generating sets overall efficiency is improved to around 80% – even more in some installations – making CHP a highly efficient energy solution.

Recovered heat can be used for a wide range of domestic, commercial or industrial uses, including space heating and hot water, process heating, as well as cooling, or even generating more power!

Heat can be recovered from the engines exhaust stream, plus its cooling, lubrication and induction systems, using heat exchangers.

Bowman manufacture a comprehensive range of CHP heat recovery heat exchangers for exhaust gas, engine and induction cooling. For more information on Bowman CHP heat exchangers

Selecting the correct heat exchanger is very important to ensure the pool heats up quickly to desired temperature. The main issues to consider when sizing a swimming pool heat exchanger are;

More information about heat exchanger selection, read the article ‘Why doesn’t my pool heat up faster?’

Selecting the correct heat exchanger is very important to ensure the pool heats up quickly to desired temperature. The main issues to consider when sizing a swimming pool heat exchanger are;

More information about heat exchanger selection, read the article ‘Why doesn’t my pool heat up faster?’

Selecting the correct heat exchanger is very important to ensure the pool heats up quickly to desired temperature. The main issues to consider when sizing a swimming pool heat exchanger are;

More information about heat exchanger selection, read the article ‘Why doesn’t my pool heat up faster?’

Bowman and Rinnai provide the perfect heating solution for an Australian roof top pool – where winter temperatures can be surprisingly cool!

Six Bowman heat exchangers have been installed at the recently opened Gold’s Gym, Amman, Jordan, to heat two half Olympic-sized swimming pools.

How Bowman heat exchangers are helping this internationally renowned golf destination reduce energy costs and CO₂ emissions.

Bowman heat exchangers are playing an important role in the success of a flagship hotel on the Black Sea coast in Georgia.

Bowman and Rinnai provide the perfect heating solution for an Australian roof top pool – where winter temperatures can be surprisingly cool!

Six Bowman heat exchangers have been installed at the recently opened Gold’s Gym, Amman, Jordan, to heat two half Olympic-sized swimming pools.

How Bowman heat exchangers are helping this internationally renowned golf destination reduce energy costs and CO₂ emissions.

Bowman heat exchangers are playing an important role in the success of a flagship hotel on the Black Sea coast in Georgia.

If you have a specific enquiry or would like to talk to one of our technical sales engineers, you can contact us by phone or email, using the contact details below. For more general enquiries, simply fill in and return the contact form for a fast response.

Tel: +44 (0)121 359 5401

E-mail: [email protected]

A network of authorised, international Bowman distributors, who hold product stocks and provide local service, is also available.