Charge Air Coolers

Used to cool the hot, compressed air from the turbo before it reaches the engine, the intercoolers improve engine efficiency and reduce emissions for marine and land-based stationary engines.

Used to cool the hot, compressed air from the turbo before it reaches the engine, the intercoolers improve engine efficiency and reduce emissions for marine and land-based stationary engines.

Exhaust gas heat exchangers are designed to recover waste heat energy from the exhaust stream of reciprocating engine powered generating sets.

Bowman 'copper free' fuel coolers are compact, highly efficient heat exchangers suitable for fuel conditioning rigs in the automotive testing industry.

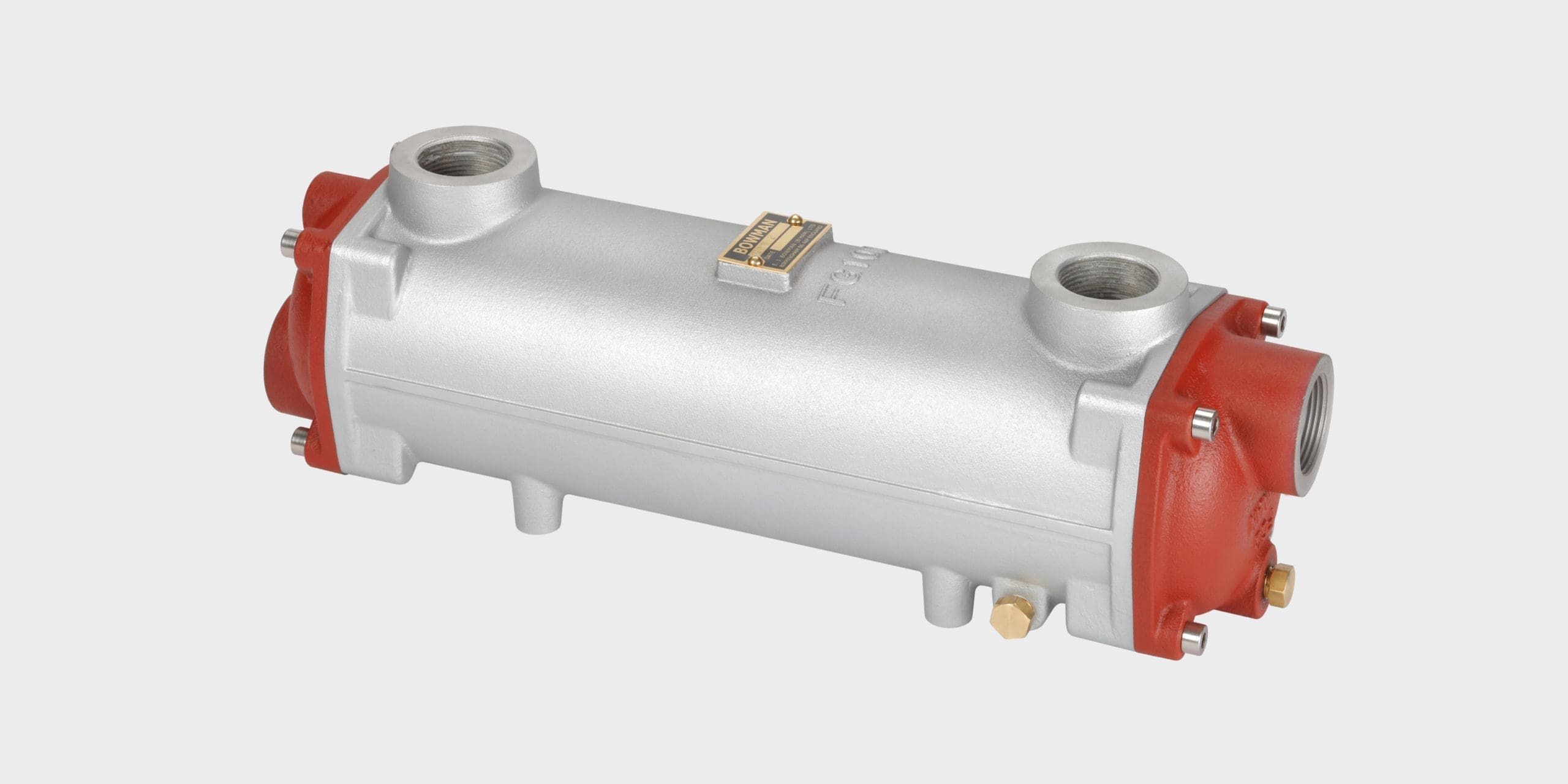

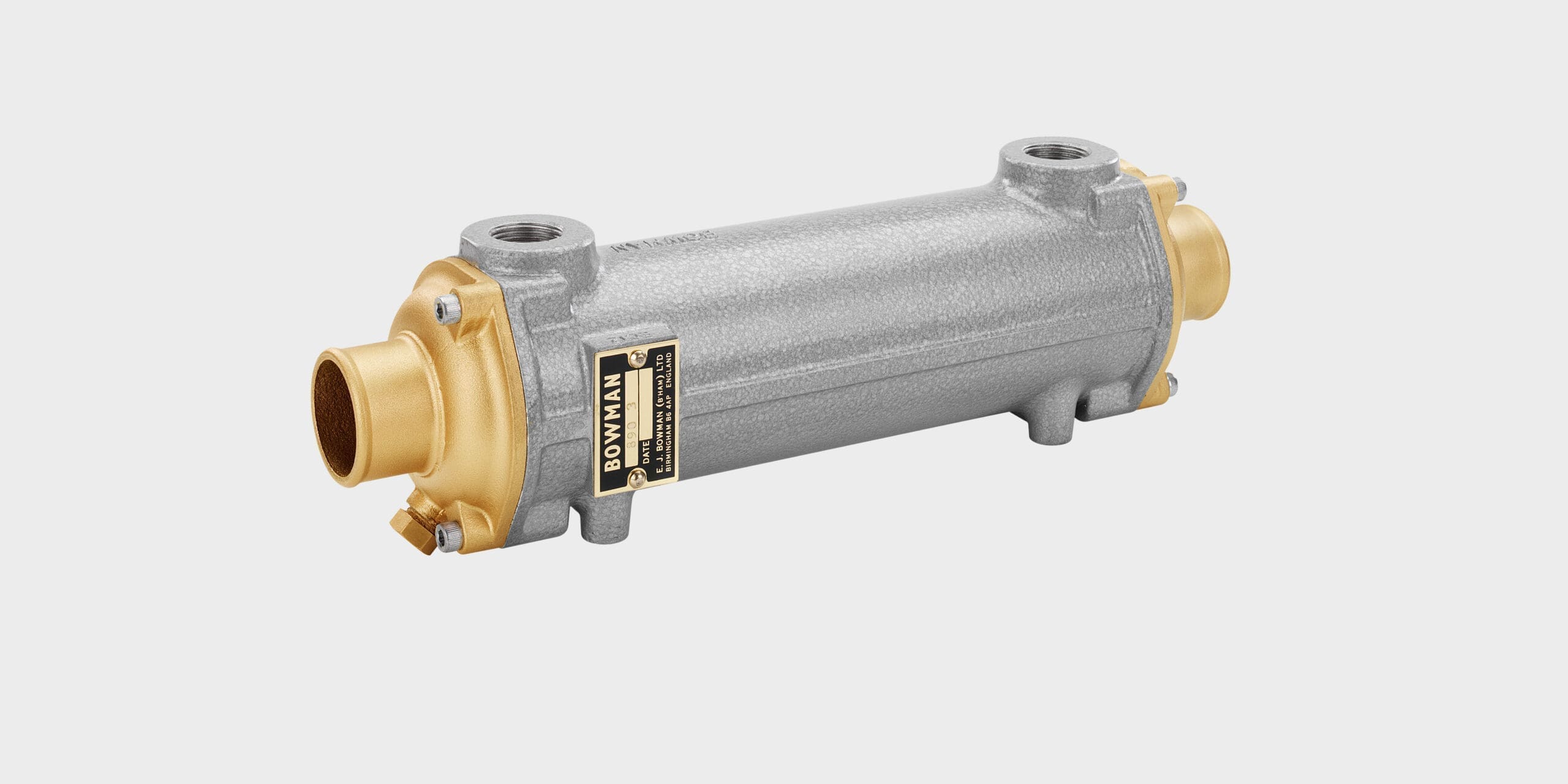

Engine coolant header tank heat exchangers for marine propulsion, gensets or stationary land-based engines.

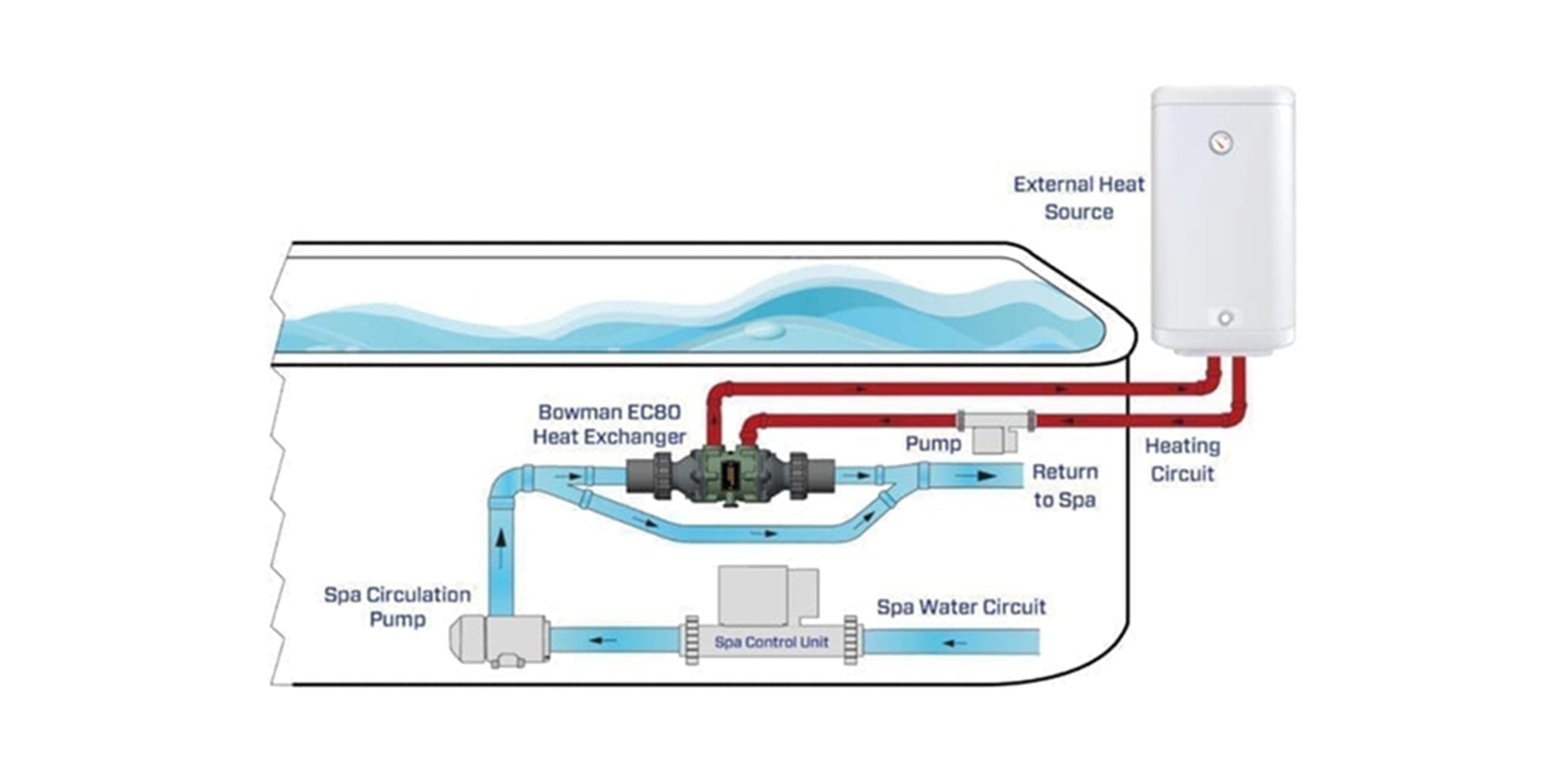

Bowman EC 80-5113-1T heat exchangers provide a new solution for heating spas and hot tubs in just a fraction of the time taken by traditional electric heaters.

Highly efficient heat transfer solutions for cooling marine, land-based and underground hydraulic systems.

Bowman inline plate heat exchangers are a compact, economical solution for high efficiency heat transfer.

Bespoke cooling solutions for a range of popular marine engines from major OEMs, including coolant heat exchangers, charge air coolers, plus combined heat exchangers and exhaust manifolds, suitable for cooling marine engines up to 1 MW.

Bowman has a range of highly efficient oil coolers designed for marine and industrial engines and transmissions.

Efficient heat exchangers for cooling electric marine motors, hydrogen fuel cells, battery packs, chargers, AC-DC converters, DC-DC converters, inverters and associated equipment for electric and hybrid marine propulsion and charging systems.

Highly efficient heat transfer solutions for cooling a variety of applications where air and fluids need to be cooled by fluids.

Many applications require stainless steel shell and tube heat exchangers and Bowman provide a standard range of units that are suitable for cooling or heating a variety of fluids.

Bowman swimming pool heat exchangers are renowned for reliability and efficiency. Whether heating your pool with a traditional boiler or a renewable energy source, Bowman is the obvious choice.

Premium quality heat exchangers and oil coolers for precise temperature control of engines under test cell development conditions.

Recovering waste heat energy from engine powered generating sets for biogas, diesel and natural gas applications up to 1 MW.

Efficient cooling for stationary / land-based engines where air cooling is either unavailable or inappropriate.

The reliable solution for cooling Electric & Hybrid Marine Propulsion Systems.

A comprehensive oil cooling solution for industrial hydraulic control systems, plus high temperature and mining applications.

A complete solution for cooling complex on-board hydraulic equipment, including thruster and stabiliser systems.

The complete cooling solution for marine engine propulsion, including the latest electric and hybrid systems.

An energy efficient solution for heating hot tubs and swim spas faster, significantly reducing heat-up time for guest change-over periods.

Quality heat exchangers for efficient swimming pool heating, using boiler or renewable energy heat sources.

Easily integrated with the engine

Provided quickly by our technical experts

Reduced noise when compared to air-cooled engines

Designed for engines up to 1500 kW

Extensive stockholding for fast response

Suitable for virtually any cooling fluid

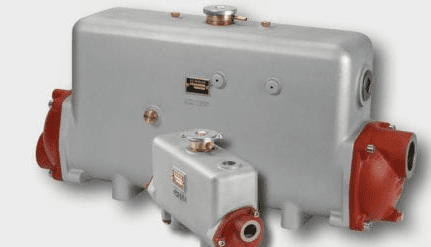

The unique ‘quiet zone’ design has a special de-aeration feature, whilst the large reservoir area above the tube stack eliminates the problem of air pockets or air locks getting into the cooling system.

Originally designed for cooling marine engines / gen-sets with sea water, Bowman header tank heat exchangers are also ideally suited for land-based engines, where fresh water is used for cooling.

Proven worldwide in applications as diverse as marine propulsion, CHP / co-generation, engine driven pumps and automotive engine testing on engines rated up to and in excess of 1 MW.

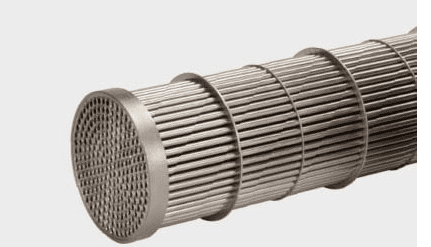

Titanium tube stacks are available as an option in place of cupronickel. The titanium materials have a 10-year guarantee and can operate at higher flow rates, compared to standard tube stacks.

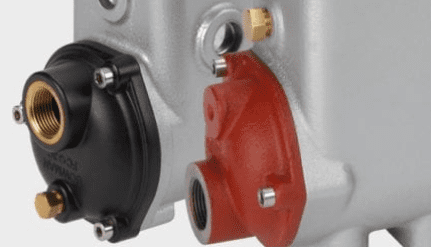

Hose connectors are provided on the most popular models for easy connection to the engine cooling water circuit. Counter flange plates are provided on larger models.

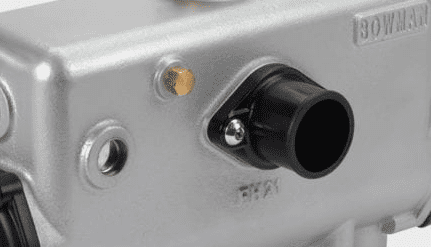

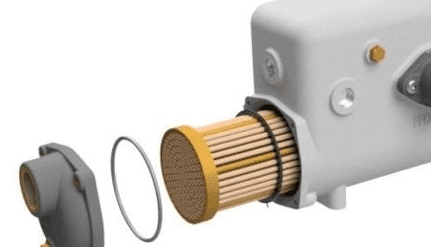

Simply by removing the end covers, the tube stack assembly can be easily withdrawn from the outer ‘shell’ for routine cleaning and maintenance. A full range of replacement parts is also available.

The following information offers a general guide to the performance and dimensions of our standard range of header tank heat exchangers. For more detailed information on additional configurations and specific applications, please download the product brochure. Computer aided selection software (CAS) is available to accurately select the correct heat exchanger specifically for your application.

Please contact us or your nearest stockist with the following information to receive a CAS selection:

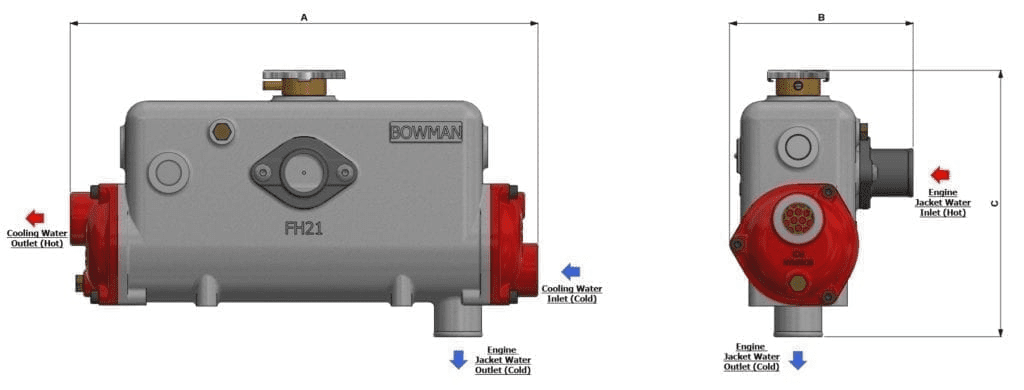

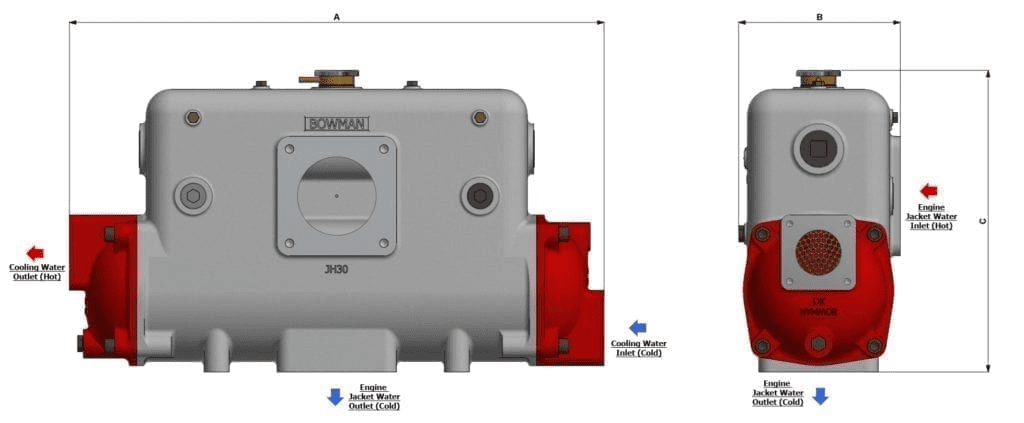

The drawings and dimensions below give general information on the product range. The drawings used are for the FH and JH products but can be used as a reference for alternative sizes in the relevant table of dimensions. For more detailed information please download the product brochure or contact us for detailed drawings.

| Type | Typical Engine Power (kW) | Max Flow - 1 Pass (l/min) | Max Flow - 2 Pass (l/min) | Max Flow - 3 Pass (l/min) | Dim A (mm) | Dim B (mm) | Dim C (mm) | Weight (kg) |

|---|---|---|---|---|---|---|---|---|

| EH100 | 40 | 180 | 85 | 54 | 260 | 150 | 240 | 5 |

| EH200 | 52 | 180 | 85 | 54 | 346 | 150 | 240 | 6 |

| FH100 | 82 | 270 | 140 | 95 | 358 | 182 | 260 | 8 |

| FH200 | 115 | 270 | 140 | 95 | 454 | 182 | 260 | 11 |

| FH300 | 150 | 375 | 190 | 125 | 472 | 208 | 327 | 14 |

| FH400 | 200 | 375 | 190 | 125 | 600 | 208 | 327 | 17 |

| GH200 | 240 | 640 | 330 | 225 | 502 | 257 | 405 | 24 |

| GH300 | 320 | 640 | 390 | 225 | 630 | 257 | 405 | 29 |

| GH400 | 400 | 640 | 330 | 225 | 776 | 257 | 405 | 34 |

| Type: EH100 | Typical Engine Power (kW) 40 | Max Flow - 1 Pass (l/min) 180 | Max Flow - 2 Pass (l/min) 85 | Max Flow - 3 Pass (l/min) 54 | Dim A (mm) 260 | Dim B (mm) 150 | Dim C (mm) 240 | Weight (kg) 5 |

| Type: EH200 | Typical Engine Power (kW) 52 | Max Flow - 1 Pass (l/min) 180 | Max Flow - 2 Pass (l/min) 85 | Max Flow - 3 Pass (l/min) 54 | Dim A (mm) 346 | Dim B (mm) 150 | Dim C (mm) 240 | Weight (kg) 6 |

| Type: FH100 | Typical Engine Power (kW) 82 | Max Flow - 1 Pass (l/min) 270 | Max Flow - 2 Pass (l/min) 140 | Max Flow - 3 Pass (l/min) 95 | Dim A (mm) 358 | Dim B (mm) 182 | Dim C (mm) 260 | Weight (kg) 8 |

| Type: FH200 | Typical Engine Power (kW) 115 | Max Flow - 1 Pass (l/min) 270 | Max Flow - 2 Pass (l/min) 140 | Max Flow - 3 Pass (l/min) 95 | Dim A (mm) 454 | Dim B (mm) 182 | Dim C (mm) 260 | Weight (kg) 11 |

| Type: FH300 | Typical Engine Power (kW) 150 | Max Flow - 1 Pass (l/min) 375 | Max Flow - 2 Pass (l/min) 190 | Max Flow - 3 Pass (l/min) 125 | Dim A (mm) 472 | Dim B (mm) 208 | Dim C (mm) 327 | Weight (kg) 14 |

| Type: FH400 | Typical Engine Power (kW) 200 | Max Flow - 1 Pass (l/min) 375 | Max Flow - 2 Pass (l/min) 190 | Max Flow - 3 Pass (l/min) 125 | Dim A (mm) 600 | Dim B (mm) 208 | Dim C (mm) 327 | Weight (kg) 17 |

| Type: GH200 | Typical Engine Power (kW) 240 | Max Flow - 1 Pass (l/min) 640 | Max Flow - 2 Pass (l/min) 330 | Max Flow - 3 Pass (l/min) 225 | Dim A (mm) 502 | Dim B (mm) 257 | Dim C (mm) 405 | Weight (kg) 24 |

| Type: GH300 | Typical Engine Power (kW) 320 | Max Flow - 1 Pass (l/min) 640 | Max Flow - 2 Pass (l/min) 390 | Max Flow - 3 Pass (l/min) 225 | Dim A (mm) 630 | Dim B (mm) 257 | Dim C (mm) 405 | Weight (kg) 29 |

| Type: GH400 | Typical Engine Power (kW) 400 | Max Flow - 1 Pass (l/min) 640 | Max Flow - 2 Pass (l/min) 330 | Max Flow - 3 Pass (l/min) 225 | Dim A (mm) 776 | Dim B (mm) 257 | Dim C (mm) 405 | Weight (kg) 34 |

| Type | Typical Engine Power (kW) | Max Flow - 1 Pass (l/min) | Max Flow - 2 Pass (l/min) | Max Flow - 3 Pass (l/min) | Dim A (mm) | Dim B (mm) | Dim C (mm) | Weight (kg) |

|---|---|---|---|---|---|---|---|---|

| KH200 | 450 | 975 | 490 | 325 | 820 | 221 | 410 | 51 |

| KH300 | 500 | 1050 | 550 | 400 | 890 | 235 | 445 | 55 |

| KH400 | 550 | 1150 | 600 | 425 | 950 | 240 | 460 | 60 |

| JH200 | 480 | 1020 | 510 | 350 | 800 | 225 | 420 | 50 |

| JH300 | 510 | 1100 | 560 | 375 | 890 | 230 | 440 | 52 |

| JH400 | 560 | 1200 | 600 | 400 | 960 | 240 | 460 | 58 |

| PH200 | 500 | 1125 | 560 | 400 | 930 | 245 | 450 | 55 |

| PH300 | 1500 | 2125 | 1050 | 700 | 1078 | 305 | 593 | 156 |

| PH400 | 1800 | 2125 | 1050 | 700 | 1280 | 305 | 593 | 190 |

| Type: KH200 | Typical Engine Power (kW) 450 | Max Flow - 1 Pass (l/min) 975 | Max Flow - 2 Pass (l/min) 490 | Max Flow - 3 Pass (l/min) 325 | Dim A (mm) 820 | Dim B (mm) 221 | Dim C (mm) 410 | Weight (kg) 51 |

| Type: KH300 | Typical Engine Power (kW) 500 | Max Flow - 1 Pass (l/min) 1050 | Max Flow - 2 Pass (l/min) 550 | Max Flow - 3 Pass (l/min) 400 | Dim A (mm) 890 | Dim B (mm) 235 | Dim C (mm) 445 | Weight (kg) 55 |

| Type: KH400 | Typical Engine Power (kW) 550 | Max Flow - 1 Pass (l/min) 1150 | Max Flow - 2 Pass (l/min) 600 | Max Flow - 3 Pass (l/min) 425 | Dim A (mm) 950 | Dim B (mm) 240 | Dim C (mm) 460 | Weight (kg) 60 |

| Type: JH200 | Typical Engine Power (kW) 480 | Max Flow - 1 Pass (l/min) 1020 | Max Flow - 2 Pass (l/min) 510 | Max Flow - 3 Pass (l/min) 350 | Dim A (mm) 800 | Dim B (mm) 225 | Dim C (mm) 420 | Weight (kg) 50 |

| Type: JH300 | Typical Engine Power (kW) 510 | Max Flow - 1 Pass (l/min) 1100 | Max Flow - 2 Pass (l/min) 560 | Max Flow - 3 Pass (l/min) 375 | Dim A (mm) 890 | Dim B (mm) 230 | Dim C (mm) 440 | Weight (kg) 52 |

| Type: JH400 | Typical Engine Power (kW) 560 | Max Flow - 1 Pass (l/min) 1200 | Max Flow - 2 Pass (l/min) 600 | Max Flow - 3 Pass (l/min) 400 | Dim A (mm) 960 | Dim B (mm) 240 | Dim C (mm) 460 | Weight (kg) 58 |

| Type: PH200 | Typical Engine Power (kW) 500 | Max Flow - 1 Pass (l/min) 1125 | Max Flow - 2 Pass (l/min) 560 | Max Flow - 3 Pass (l/min) 400 | Dim A (mm) 930 | Dim B (mm) 245 | Dim C (mm) 450 | Weight (kg) 55 |

| Type: PH300 | Typical Engine Power (kW) 1500 | Max Flow - 1 Pass (l/min) 2125 | Max Flow - 2 Pass (l/min) 1050 | Max Flow - 3 Pass (l/min) 700 | Dim A (mm) 1078 | Dim B (mm) 305 | Dim C (mm) 593 | Weight (kg) 156 |

| Type: PH400 | Typical Engine Power (kW) 1800 | Max Flow - 1 Pass (l/min) 2125 | Max Flow - 2 Pass (l/min) 1050 | Max Flow - 3 Pass (l/min) 700 | Dim A (mm) 1280 | Dim B (mm) 305 | Dim C (mm) 593 | Weight (kg) 190 |

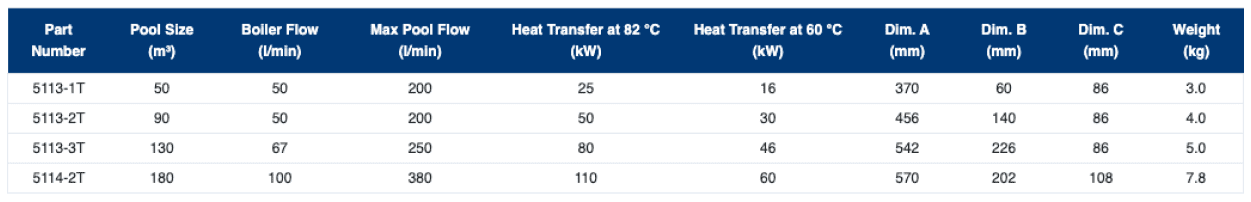

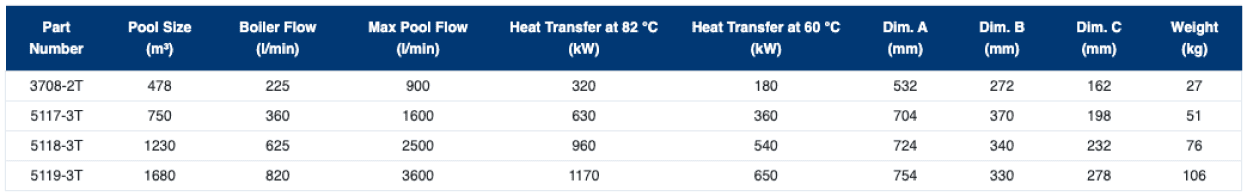

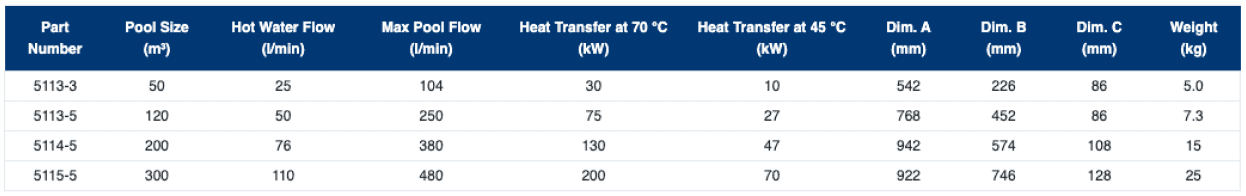

The table below enables the selection of the most appropriate heat exchanger for your swimming pool or spa. The information shows the amount of heat that can be transferred from either boiler or renewable energy sources, together with the basic dimensions of each unit. Typical pool sizes are also shown as a guide. For further information please download the product brochure, contact us or your nearest stockist.

Note – Ratings and weight are specifically relevant to the titanium versions of each heat exchanger. Download the brochure for more detailed information.

Note – Ratings and weight are specifically relevant to the titanium versions of each heat exchanger. Download the brochure for more detailed information.

Note – Ratings and weight are specifically relevant to the titanium versions of each heat exchanger. Download the brochure for more detailed information.

Note – Weight provided are for the titanium versions.

For spas, hot tubs and small private pools

For mid sized private and commercial pools

For large commercial and public pools

For more information on JK190-5118-3 and PK190-5119-3 please contact Bowman.

For transferring heat from solar panels and heat pumps

For spas, hot tubs and small private pools

For mid sized private and commercial pools

For large commercial and public pools

For more information on JK190-5110-3 and PK190-5111-3 please contact Bowman.

For transferring heat from solar panels and heat pumps

No download content found.

Technical sales brochure includes product information, ratings charts, drawings and dimensions for the standard product range.

Technical sales brochure includes product information, ratings charts, drawings and dimensions for the standard product range.

Technical sales brochure includes product information, ratings charts, drawings and dimensions for the standard product range.

Technical sales brochure includes product information, ratings charts, drawings and dimensions for the standard product range.

Technical sales brochure includes product information, ratings charts, drawings and dimensions for the standard product range.

Technical sales brochure includes product information, ratings charts, drawings and dimensions for the standard product range.

Technical sales brochure includes product information, ratings charts, drawings and dimensions for the standard product range.

Technical sales brochure includes product information, ratings charts, drawings and dimensions for the standard product range.

Technical sales brochure includes product information, ratings charts, drawings and dimensions for the standard product range.

Technical sales brochure includes product information, ratings charts, drawings and dimensions for the standard product range.

Technical sales brochure includes product information, ratings charts, drawings and dimensions for the standard product range.

Technical sales brochure includes product information, ratings charts, drawings and dimensions for the standard product range.

Technical sales brochure includes product information, ratings charts, drawings and dimensions for the standard product range.

Technical sales brochure includes product information, ratings charts, drawings and dimensions for the standard product range.

A heat exchanger is a device for transferring heat energy from a liquid or gas, to another liquid or gas without the two ever coming into contact with each other. A typical shell and tube heat exchanger will contain a tube bundle inside an outer shell, or body. Cold water flows through these tubes, whilst hot water, or gas flows around the outside of the tubes, enabling the heat from the hot water or gas to be transferred to the colder water inside the tubes.

A good example of how the process works are swimming pools, where most are heated via a boiler, using Gas, LPG or Biomass as the energy source. In theory, the most efficient way to heat the pool would be to circulate the pool water directly through the boiler. But were this to happen, the chemicals used in the pool water to keep it safe for use, would quickly corrode and damage vital parts inside the boiler, leading to premature failure and a costly replacement.

However, by using a heat exchanger to act as an ‘interface’ between the boiler water circuit and the pool water circuit, the boiler is protected from damage and the pool water is quickly heated up to the required temperature; the pool water passing through the central ‘tube core’, whilst the hot boiler water circulates around the outside of the tubes, transferring heat energy to the pool water.

More examples of applications where Bowman heat exchangers are used.

During the course of its operating life, a shell and tube heat exchanger will need cleaning many times. Both fresh water and sea water cooling media today contain high levels of minerals and pollutants, which can build up over time, restricting the water flow through the tube core, resulting in a reduced flow rate and significantly lower heat transfer efficiency.

The good news is that Bowman shell and tube heat exchangers are much easier to clean than many other types and the following information is intended as a basic guide:

For more detailed information on care and maintenance of your Bowman heat exchanger or oil cooler, download a copy of our ‘Installation, Operation & Maintenance guide’.

Many water cooled internal combustion engines (ICE), can be adequately cooled, simply by pumping the engines coolant through an air cooled radiator.

Cooler ambient air is drawn into and through the radiator by a cooling fan, transferring heat from the engine coolant as it is pumped through the radiator.

But there are applications where air cooling is either less efficient or not an option for an ICE. This could be due to insufficient air flow, or ambient air temperatures being too high, and in these situations, water cooling is a proven solution. Moreover, replacing the radiator with water cooled heat exchangers can save valuable space and considerably reduce noise.

Installing water cooling is quite straightforward as instead of a radiator, a heat exchanger, usually of ‘shell and tube’ design, is installed into the engines cooling system.

The heat exchanger has two circuits; one will be connected to the engines cooling circuit and the other connected to a source of cool water, which could be seawater for a marine engine or fresh water for applications such as irrigation systems, power generation, fire protection or automotive engine testing.

The cooling water is pumped through a central tube core in the heat exchanger, whilst the engines coolant flows over and around the outside of the tubes, transferring heat from the engines coolant circuit to the cooling water as it flows through the unit.

Whilst there are many heat exchangers suitable for cooling engines, Bowman’s Header Tank units are particularly successful due to the design, which incorporates and integral expansion chamber above the tube core. This eliminates the problem of air pockets or air locks getting into the cooling stream. There is also has a special de-aeration feature, plus pressurised filler cap, making integration very much easier. For more information on Bowman Header Tank Heat Exchangers

Selecting the correct heat exchanger is very important to ensure the pool heats up quickly to desired temperature. The main issues to consider when sizing a swimming pool heat exchanger are;

More information about heat exchanger selection, read the article ‘Why doesn’t my pool heat up faster?’

Selecting the correct heat exchanger is very important to ensure the pool heats up quickly to desired temperature. The main issues to consider when sizing a swimming pool heat exchanger are;

More information about heat exchanger selection, read the article ‘Why doesn’t my pool heat up faster?’

Selecting the correct heat exchanger is very important to ensure the pool heats up quickly to desired temperature. The main issues to consider when sizing a swimming pool heat exchanger are;

More information about heat exchanger selection, read the article ‘Why doesn’t my pool heat up faster?’

Bowman and Rinnai provide the perfect heating solution for an Australian roof top pool – where winter temperatures can be surprisingly cool!

Six Bowman heat exchangers have been installed at the recently opened Gold’s Gym, Amman, Jordan, to heat two half Olympic-sized swimming pools.

How Bowman heat exchangers are helping this internationally renowned golf destination reduce energy costs and CO₂ emissions.

Bowman heat exchangers are playing an important role in the success of a flagship hotel on the Black Sea coast in Georgia.

Bowman and Rinnai provide the perfect heating solution for an Australian roof top pool – where winter temperatures can be surprisingly cool!

Six Bowman heat exchangers have been installed at the recently opened Gold’s Gym, Amman, Jordan, to heat two half Olympic-sized swimming pools.

How Bowman heat exchangers are helping this internationally renowned golf destination reduce energy costs and CO₂ emissions.

Bowman heat exchangers are playing an important role in the success of a flagship hotel on the Black Sea coast in Georgia.

If you have a specific enquiry or would like to talk to one of our technical sales engineers, you can contact us by phone or email, using the contact details below. For more general enquiries, simply fill in and return the contact form for a fast response.

Tel: +44 (0)121 359 5401

E-mail: [email protected]

A network of authorised, international Bowman distributors, who hold product stocks and provide local service, is also available.